- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- repairs

Results for

Repairs - Import export

LLOYD DYNAMOWERKE GMBH

Germany

The repair works are located at our site in Bremen. Through the utilisation of all the resources of our manufacturing operations our customers enjoy all the benefits of repairs, maintenance and reconditioning in accordance with the DIN IEC60034-23 standard. For work on explosion-proof machines we can provide all the certificates required for order fulfilment in full compliance with legal provisions. LDW has a certified expert and the legally binding permits ATEX, PTB KTE etc. required for a professional execution. All AEG documents from around 100 years of electrical engineering are available in their entirety within our company. This enables us to carry out repairs, supply spare parts or complete machines that are electrically and mechanically interchangeable. As part of this process we upgrade these procedures in step with the latest technological developments. The energy balance is thereby significantly improved on a regular basis.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The SG 175 support grinder is designed for grinding the conical seating surface of valves of medium speed diesel engines on a standard lathe. Handling The support grinder is clamped in the toolpost located on the top slide of the lathe. The grinding angle corresponding to the required valve seat angle is adjusted by turning the top slide of the lathe to an angular position which corresponds to the valve seat angle and which is defined by the template supplied with the grinder. The valve stem is clamped in the chuck of the lathe and the valve face is ground by feeding the grinding wheel into the rotating valve face. Features The precision grinding spindle is permanetly sealed and lubricated for lifetime accuracy. The wheel guarding system is designed to the prevailing safety regulations. The cone-shaped head of the template is provided with a bore receiving the dressing diamond so that the grinding wheel can be properly dressed after adjustment of the grinding angle.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Selfcentering Steady (Option) Selfcentering steady rests are available to fit on the swivel plate slideway for additional support of long stem valves. Both the workhead and the stready rest are adjustable along the swivel plate to clamp each valve on that part of the valve stem which normally travels in the valve guide. The combination of collet chucking and the unique Hunger steadying provides double support of long valves to ensure the ultimate in valve refacing accuracy. Oscillating Equipment (Option) An oscillating equipment for automated power traverse of valve face across the grinding wheel is available to ensure efficient stock removal and superior finish. The stroke of oscillation is infinitely adjustable. Automated Infeed (Option) Power infeed is available for automatic grinding according to a preselected program. The feed rate, the total infeed and the sparkout time can be easily selected.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure with integrated dove tailed slideway for the workhead and steady rest. The machine base houses an industrial type flood pump for delivering coolant to the grinding site and a baffled drawer type coolant reservoir which can be drawn out for ease of cleaning. The machine base houses also the control panel for the motors. Grinding Spindle The permanently sealed and lubricated grinding spindle slides on a swivel plate which is provided with an integrated dove tailed slideway. The swivel plate is set to the desired valve angle by means of a wide spaced scale. Steady Rest An unique selfcentering steady rest is provided for additional support of long stem valves. Both the workhead and the stready rest are adjustable along the slideway on the machine base to clamp the valve on that part of the valve stem which normally travels in the valve guide.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure with integrated dove tailed slideway for the workhead and steady rest. The machine base houses an industrial type flood pump for delivering coolant to the grinding site and a baffled drawer type coolant reservoir which can be drawn out for ease of cleaning. The machine base houses also the control panel for the motors. Grinding Spindle The permanently sealed and lubricated grinding spindle slides on a swivel plate which is provided with an integrated dove tailed slideway. The swivel plate is set to the desired valve angle by means of a wide spaced scale. Steady Rest An unique selfcentering steady rest is provided for additional support of long stem valves. Both the workhead and the stready rest are adjustable along the slideway on the machine base to clamp the valve on that part of the valve stem which normally travels in the valve guide.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure with integrated slideway for wheelhead. The machine base houses an industrial type flood pump for delivering coolant to the grinding site and a baffled coolant tank which can be drawn out for ease of cleaning. Workhead and Steady Rest Both the workhead and the steady rest are adjustable along the swivel plate to clamp each valve on that part of the valve stem which normally travels in the valve guide. The combination of collet chucking and the unique Hunger steadying provides double support of long valves to ensure the ultimate in valve refacing accuracy. Automated Oscillation An oscillating equipment for automated power traverse of valve face across the grinding wheel is available as an option to ensure efficient stock removal and superior finish. The stroke of oscillation is infinitely adjustable.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Machine Base Heavily ribbed cast iron structure for vibration-free performance. Adjustable slideways for wheelhead infeed and workhead traverse. Wheelhead Box type monobloc noted for its excellent vibration dampening characteristics. The precision motor grinding spindle is permanently sealed and lubricated. Workhead Located on a swivel plate which can be set to the required angular position by means of a wide-spaced scale. Collets for perfect valve alignment. Dressing Attachment The dressing attachment is permanently mounted on the worktable for rapid wheel dressing. Wet Grinding Coolant is delivered by an industrial type flood pump. The baffled coolant tank is easily removed from the machine base for cleaning. Electrical System Individual grinding spindle motor, work spindle motor and coolant pump motor all controlled by switches grouped in front of the wheelhead for ease of operation.

Request for a quote

KLN ULTRASCHALL AG

Germany

Our skilled service team is at your disposal for questions about our products as well as technical problems. Our services: • maintenance of all KLN-machines • training • cost-free Hotline (the service is free of charge, only the standard telephone costs will be charged. • augmented support • annual examination of BWS (contactless active protective device) • examination according to DGUV V3 • spare parts • repair center • repair offers free of charge • determination of adaption values of generators (cleaning sector) with special measuring devices • lifelong service installation files of all KLN machines The best day for good service is today!

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Competent, reliable and efficient. As experienced grab systems specialists, we professionally repair and restore all makes of grabs. We always have the main spare parts for KROGER rope and motor grabs in stock in our warehouse, whether you require them for a revision, quick on-site damage repair, repairs caused by wear-and-tear or refurbishment. We either make quick repairs on site or take your machinery to our workshop for more comprehensive refurbishments. Contact us, we will be happy to advise you.

Request for a quote

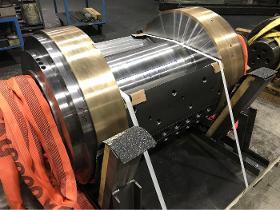

MIBA INDUSTRIAL BEARINGS

Germany

Miba Industrial Bearings provides a center of excellence in babbitted bearing manufacturing, repair, labyrinth seal optimization as well as troubleshooting, failure analysis, engineering solutions and upgrades.

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

Some 3,000 different types of brushes in our off-the-shelf store are just waiting to go into action. And if the right one is not amongst them, we will design a customised solution to help out in an emergency. You have a problem, we solve it – that’s the deal. Whether in the course of regular machine maintenance or an unexpected repair job: We can supply a broad range of replacement parts within 24 hours, starting with single parts. Because we have decades of experience in stocking carbon brushes. For special individual productions, we coordinate with you using photographs or construction drawings, then make samples of your requirements, produce the required tooling, and move quickly into production and assembly. Carbon brushes and brush holders from a single provider. And if you like it easy, then our Carbon brush configurator can ‘advise’ you. Using the online tool you can easily make enquiries about or order typical small and industrial carbon brushes directly.

Request for a quote

GMN PAUL MÜLLER INDUSTRIE GMBH & CO. KG

Germany

With more than ten GMN authorized GMN service centers throughout the world, we offer our customers over 80 years of experience in the development and production of machine spindles. Our extensive service network ensures that we can offer expert advice as well as long term maintenance and quick repairs. If the spindle function is compromised, GMN service technicians are on-site quickly to ensure that our customers maintain maximum productivity. Equipped with the latest technology, GMN repair service guarantees a detailed cause analysis and professional service – worldwide.

Request for a quote

WELTE CARDAN-SERVICE GMBH

Germany

Welte Cardan-Service GmbH has developed into a leading company in the cardan shaft industry since 1972. Thanks to our many years of experience in the repair and overhaul of drive shafts and cardan shafts, we guarantee a rapid maintenance process with short delivery times, always optimised in line with our quality standards. Our maintenance service enables you to carry out the repair of almost any cardan shaft quickly.

Request for a quote

ING. KURT SCHADE GMBH & CO. KG

Germany

Our many years of experience in the fields of steel construction and CNC machining also make us a competent service provider in the field of repairs. Contact us – together we will find the optimal solution!

Request for a quote

MALEKI GMBH

Germany

Versatile environmentally friendly repair mortar for concrete and masonry. For repair and coating work. Maleki-RM 500 is ideal for filling holes and cavities, especially on wall surfaces. Due to the rapid setting of the mortar, surfaces can be prepared quickly and cost-effectively for further coating work. Packaging unit: 25 kg paper bag, 1050 kg per pallet – Article-No.: 1416

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Repair or maintenance of fans. Repairs Fan impellers are often subject to high degrees of wear due to the solids in the conveying medium. Preventative maintenance helps to save costs, because a completely destroyed impeller can only be replaced by a new one. An impeller that is only partly damaged can easily be repaired and is comparable to a new impeller with regard to its subsequent service life. Naturally we also repair fans not made by us. Balancing and inspection of bearings The increasing demands on the performance, smooth running, weight, quality and life span of machines mean that increasing importance is also attached to mechanical vibrations. Balancing helps in most cases to eliminate the vibrations or at least to reduce them to an acceptable level. The fact that mechanical vibrations are not only unpleasant but also damaging is shown by a drastic shortening of the lifetime of gearboxes and roller bearings as well as the occurrence of fatigue fractures or unacceptable noise. The diagnosis is imbalance or bearing damage. Both causes result in elaborate repair work. While the bearings can be exchanged by the user’s service technicians, external services are required for the balancing of a fan impeller, since a balancing machine and special know-how are needed for this. Rippert uses state-of-the-art balancing machines in accordance with DIN ISO 1940 for this. Stationary balancing Rotor size: max. DN 4,000 mm Rotor weight: max. 10,000 kg Measuring procedure: force measurement Balancing quality: Q 6.3* * other qualities on request On-site balancing In addition to stationary balancing in the factory, Rippert also offers on-site balancing. This saves elaborate disassembly and assembly work as well as time-consuming and, depending upon size of the impeller, expensive transport.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for any strained indoor vinyl surfaces or superficially scratched. Vinyl Repair effectively diminishes superficial scratches. It simultaneously maintains and protects the surface. Transparent when dry.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PNZ-PRODUKTE GMBH

Germany

Suitable for mending damages, scratches and small defects on any wooden surface indoors such as doors and furniture, wall panels and wooden parts. Retouching Pen distinguishes itself by virtue of its high quality. Ideal for any wooden surface. Easy use, instant result. The beveled tip guarantees easy application, even in corners and angles

Request for a quote

ALPHA LASER GMBH

Germany

The ALM laser system is particularly suitable for welding large molds and tools, housings and machine components - wherever mobility and maneuverability are required. With the ALM you have exactly the mobility you need for welding. No matter whether in your own workshop or on site at the customer. The laser is ready for use within a few minutes. The arm can be quickly adjusted to the area to be welded and fixed in the desired working position using electro-hydraulic brakes. The operator then has the option of welding manually using a joystick or semi-automatically. One or more axes are automatically moved at a preset speed and with the joystick curves can be driven or small corrections made.

Request for a quote

ALPHA LASER GMBH

Germany

Suitable also for welding precision mechanical parts and medical technology components as well as for the manufacture of sensors and electrical components The ALS 100 is an ergonomic workplace The spacious work chamber offers a very brightly lit work area and is loaded via two side doors. The average power of 100 W enables a fast pulse sequence (up to 25 Hz) and thus fast work even at high energy settings. The homogeneous fusion of the materials results in welding results of the highest quality. The laser is used in the manufacture and repair of jewelry, in precision engineering or when welding sensors

Request for a quote

ALPHA LASER GMBH

Germany

The desktop laser welding machine delivers with 50 watts good beam power and is characterized by its uniform, powerful, yet soft welding behaviour. The manual welding laser VL 50 has a very spacious working chamber and allows to weld precious metals such as silver and gold due to its powerful laser behaviour. Longer concentrated work is easily possible thanks to the ergonomically designed housing with the well thought-out arrangement of keyboard, display and joystick. The desktop laser VL 50 is a valued tool in the manufacture and repair of dentures and jewelry, in welding on precision parts, medical technology components and sensors, but also when applying materials to small molds.

Request for a quote

ALPHA LASER GMBH

Germany

You won’t get it more flexible. The mobile welding laser AL-ARM was developed to quickly and flexibly repair offset seams, pores and penetrations in the car body. The fiber laser system can be positioned quickly and has a long range. The 3D visualization with integrated laser safety glasses enables the user to observe his welding task as well as the surroundings. The welding process is shown enlarged and the process-relevant data is also visible in the image. The handpiece, which is used for welding, is equipped with an automated wire feed and an integrated shielding gas nozzle. It weighs just 1.5 kg and is easy to position. There is no set-up time for welding.

Request for a quote

SPINDEL- UND LAGERUNGSTECHNIK FRAUREUTH GMBH

Germany

One of the most significant and functionally important components of working machines is their spindle unit. It operates as guidance and drive of tool respectively work piece. It is very important that its function is fulfilled precisely. As a manufacturer of a wide range of machining spindle units naturally short-term maintenance and repairs belong to our service package. In addition to repair of our own products we are also able to repair spindle units with bearings made by other manufacturers. Examination on receipt / disassembling Quotation Rework / remanufacture Assembly Test run Test certificate

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

Repair Kits Related Links DM Advantage Training Online Catalog QuickShip Program Literature Order Center Video Library Related Products DM Advantage Two-Speed Fan Drives PolarForce Two-Speed Conversion Kits DM Advantage Reman Fan Drives DM Advantage Repair Kits WindMaster Fans WM Revolution Fans WindShift Modular Fans To maximize DM Advantage's performance, depend on DM Advantage Repair Kits. Designed to handle the demanding high-torque, high-heat requirements of today's more powerful diesels, these parts ensure top vehicle performance, unrivaled fuel efficiency, and savings you'll see on your bottom line. DM Advantage Super Kits include a fan mounting disc, clutch pak, sheave bearing, O-rings, friction liner, air cartridge, face seal, retaining rings, facing screws and lubricant. These kits allow the rebuilding of a DM Advantage to new condition in about 30-45 minutes. DM Advantage Seal Kits include everything you need to eliminate an air leak in fifteen minutes: O-rings, retaining rings, facing screws, air cartridge, face seal and lubricant. DM Advantage Friction Disc Kits include a fan-mounting disc, friction liner and facing screws — allowing the replacement of a worn-out disc and liner in fifteen minutes. DM Advantage Friction Liner Kits include a friction liner and facing screws. Liner replacement can be completed in about fifteen minutes. All Horton Repair Kits feature Genuine Horton Parts. DM Advantage Bearing Kits include a sheave bearing, bearing nut and retaining ring. Bearing kits are designed for repairs requiring fewer parts than a super kit. DM Advantage Clutch Pack Kits include an O-ring lubricant, facing screws, air cartridge seal, spring housing/piston. Clutch Pack Kits repair the clutch pack. PolarForce Two-Speed Conversion Kits include an O-ring seal, fan mounting disc, button head screws, air chamber seal, face seal, retaining ring, friction liner, spring housing/piston, magnet assemblies. Whether you're looking to upgrade your fleet's performance or needing torque enough to turn today's 32-inch diameter fans, DM Advantage is the answer. Related Products - DM Advantage On/Off Fan Drives - DM Advantage Reman On/Off Fan Drives - DM Advantage Two-Speed Fan Drives - DM Advantage Reman Two-Speed Fan Drives - PolarForce Two-Speed Conversion Kits - WindMaster Fans - WindMaster Revolution Fans - WindShift Fans - Shogun Fans Links - DM Advantage Training - Order or View Literature - On-line Catalog

Request for a quoteSKINOVATORS GMBH

Germany

The SOS skin care concentrate soothes sun-stressed skin and counteracts moisture loss with ectoin and hyaluronic acid. The vitamins A and E with their antioxidant properties are aimed at neutralizing the free radicals caused by UV irradiation and protecting against sun-induced skin aging. Panthenol has a skin soothing effect. The concentrate is free of PEGs, parabens and mineral oils.

Request for a quote

BAUER GMBH

Germany

-sturdy construction made of round pipes -nonslip access safety platform -number of persons permitted: 2 -through fork sleeves with safety mechanism to prevent slipping -underrun protection device ensures pick-up via fork sleeves -with galvanized tool deposit -approved by the german technical inspection agency “TÜV”, in compliance with the "BGV" (German accident prevention regulations) Types available -Type SIKO picked up lengthwise by a forklift truck -Type SIKO/L picked up crosswise by a forklift truck Accessory -2 swivel + 2 fixed polyamide castors Ø 180 mm, one swivel castor with brake - construction height 220 mm

Request for a quote

KURO KUNSTSTOFFE GMBH

Germany

The challenging nature of civil engineering demands high quality protection from external loads. We can offer you a diverse cable protection programme for use in the power industry, traffic technology and communication technology.. Our strategic manufacturing relies on the highest standards for quality and accuracy in accordance with DIN 8061/62 und DIN 16873. Sophisticated quality controls and short lead times enable a fast and smooth transfer of your cable protection pipes. Are you looking for a solution to meet your specific requirements? Why not take advantage of our customized solutions in our workshop and utilize our wealth of experience.

Request for a quote

KURO KUNSTSTOFFE GMBH

Germany

The challenging nature of civil engineering demands high quality protection from external loads. We can offer you a diverse cable protection programme for use in the power industry, traffic technology and communication technology.. Our strategic manufacturing relies on the highest standards for quality and accuracy in accordance with DIN 8061/62 und DIN 16873. Sophisticated quality controls and short lead times enable a fast and smooth transfer of your cable protection pipes. Are you looking for a solution to meet your specific requirements? Why not take advantage of our customized solutions in our workshop and utilize our wealth of experience.

Request for a quote

METZEN INDUSTRIES GMBH

Germany

We are well prepared for quick repairs, which means shorter downtimes for our clients. We know what downtime means for our customers. Which is why we develop and manufacture superior, robust products. Our maintenance-free rope and motor grabs contribute to both environmental protection and economic efficiency. Because maintenance-free means no need for lubricants, no time spent greasing and no wear. However, even our KROGER grab sometimes require spare parts, inspections or repairs after repeatedly lifting maximum loads. We are here to help you when you need it. We can guarantee quick repair as we always have access to our KROGER grab ’ spare parts. We will ship the required parts to you as quickly as possible. The use of original KROGER spare parts can improve your grabs’ long-term performance. Please refer to your grab’s technical documentation for its spare parts delivery scope.

Request for a quoteResults for

Repairs - Import exportNumber of results

43 ProductsCountries

Company type

Category

- Paint mixers and grinding machines (6)

- Car body repair shops - services (5)

- Tyres - repair supplies (5)

- Laser - cutting and welding machines (4)

- Hydraulic equipment (2)

- Repairs - industrial equipment (1)

- Tools & Hardware (1)

- Plumbing, domestic (1)

- Basket lifts (1)

- Building materials (1)

- Electroheat - machines and equipment (1)

- Fittings, pipe, tube and hose - plastic (1)

- Folding, bending and welding of rubber and plastic (1)

- Mechanical engineering - custom work (1)

- Plain bearings (1)

- Rolling machines (1)