- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rate controls

Results for

Rate controls - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

A flow valve is a critical component in various systems where the regulation of fluid flow is necessary. It’s designed to control the rate at which fluid passes through a system, ensuring that the flow matches the requirements of the application.Flow control valves are essential in industrial usage, hydraulic systems, and pneumatic systems. They play a crucial role in regulating the flow of fluids, ensuring optimal performance and efficient operation of machinery and equipment. Control valves can be actuated in various ways, including pneumatically, hydraulically, or with electric motors. Some valves, known as automatic control valves, do not require an external power source and operate solely on fluid pressure.When selecting a flow control valve, it’s important to consider factors such as flow rate and pressure requirements, material compatibility, and environmental conditions.

Request for a quote

INFICON GMBH

Germany

Advanced, Affordable Rate Control for Single or Multiple Layers Now get everything you want in a thin film deposition controller for single and multiple-layer processes. The XTC/3 with patented ModeLock provides proven mode hop prevention for consistent quality. With the XTC/3 Thin Film Deposition Controller, you get highly accurate control of deposition rate and thickness, the capacity for virtually any number of layers, easy installation, and extremely high reliability to ensure productivity. INFICON, the global leader in thin film deposition control, now offers an instrument with a remarkably low cost of ownership for unprecedented value. Whether your control needs reflect production or research and development use, you will find a precise match in the INFICON XTC/3. Worldwide INFICON Support No matter where you are, you get fast answers, attentive service, and maximum uptime. With offices around the world, INFICON is the only manufacturer of thin film deposition...

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Electromagnetically operated pinch valve PPV 7 (NC) with high flow rates and precise control. The 2/2-way NC pinch valve clamps tubes with a Diameter up to 7mm and depending on the used material (PVC / Silicone) up to 1.5mm wall thickness. It has a clamping force of 42N.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Electromagnetically operated pinch valve PPV 7 (NO) with high flow rates and precise control. The 2/2-way NO pinch valve clamps tubes with a Diameter up to 7mm and depending on the used material (PVC / Silicone) up to 1.5mm wall thickness. It has a clamping force of 42N.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Pivot pins are found on shutoff devices such as spherical valves, butterfly valves, hollow jet valves and plunger valves. These valves are generally used for opening and closing and occasionally to control the flow rates by oscillating movement. The greaselubricated sliding bearing is protected against water infiltration by a seal on the inside. The seal also prevents the grease leaking into the inside to prevent water contamination. The MANOY® system seal WP, type 418, was developed for this application. To prevent leakage of grease from greased bearings, the unidirectional MANOY® system seal WP, type 456, is also installed.

Request for a quote

PETER HUBER KÄLTEMASCHINENBAU SE

Germany

The new Grande Fleur expands the product offering in the dynamic temperature control range. The Grande Fleur together with the Petite Fleur are two small Tangos and are the entry level into the world of Unistat technology. The compact dimensions and unique thermodynamics of the Grande Fleur mean it is ideally suited for high precision temperature control of research reactors. The Grande Fleur offers all of the great performance and features of the Unistat series, achieving unrivalled heating and cooling rates. The new multi-touch controller Pilot ONE offers a brilliant 5.7" touchscreen with graphic functions and a comfortable navigation menu. All important operating parameters and temperature values are neatly displayed on the touchscreen. Thanks to the new favourites menu, the one-click operation and the integrated technical glossary the operation is very easy, just like on a smartphone. Integrated USB and Ethernet ports allows connection to a PC or network, e.g. for remote...

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ N082, N182 and N782 pressure reducers ensure that a constant outlet pressure is maintained in process plant utilizing the pressure differential.If the pressure rises on the outlet side, the spring force is lower and the valve closes as the spring is raised. The pressure is reduced until the spring force and the outlet pressure are the same. If the pressure falls, the valve opens as the spring force presses against the diaphragm surface via the control aperture. The outlet pressure can be read off a diaphragm-protected pressure gauge (not available for N782) and the spring force adjusted using a set screw as required. - The working pressure can be very easily adjusted using a set screw and secured with the integrated lock nut. If required, the setting that has been made can be lead sealed - The flow-efficient design of the valve body ensures good flow rate values - Control errors are kept to a minimum due to the large control face and the spiral spring

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The patented gwk solution includes cold water temperature controllers that can be operated without glycol in the temperature range between 0 °C and 25 °C. The user can select between two models that are differing in cooling capacity and flow rate. A precise microprocessor control with simultaneous indication of nominal and actual value, the simple one-touch operation, optional interfaces at the front panel and external sensor connection, splash-water proofed electrics and the cabling with CEE-socket ready for connection make the unit ready for immediate use. Leak stop operation, mould draining, acoustic alarm, automatic filling and top up, additional manual filling possibility for conditioned water, strainer in the cooling water connection and parts out of corrosion resistant materials that are in contact with the medium are part of the comprehensive standard equipment.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The teco cs series was improved by installation of a user-friendly touch screen with new, integrated functions. All standard units are equipped with an energy efficient constant heating control. Depending on the product version a flow rate measurement and control, whose actual value is indicated simultaneously with the actual and nominal values on the colour screen, is installed as standard or is optionally available. Temperature profiles are graphically indicated after selection of the corresponding menu function. On the start page useful functions like limit value monitoring, leak stop operation etc. can be selected. The proven teco cs series was improved by installation of a user-friendly touch screen with new, integrated functions. The 95°C series was extended by three versions with higher capacities. The models are designed for larger consumers; they have heating capacities from 18 to 36 kW, cooling capacities from 50 to 120 kW and pump flow rates from 110 to 170 l/min.

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Valve Island VI Nom.width (mm) Flow rate (l/min) Control 6 800 Profi-Bus simultaneous vacuum control of several suction circuits

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Reversing Valve UV Nom.width (mm) Flow rate (l/min) Control 10 ... 25 6.000 ... 6.960 24 V DC / 230 V directly controlled vacuum valve to control suction circuits when using blowers

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Impulse Valve IMV Nom.width (mm) Flow rate (l/min) Control 10 ... 25 350 ... 1.350 24 V DC / 230 V directly-controlled, bistable vacuum valve to control individual suction circuits

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

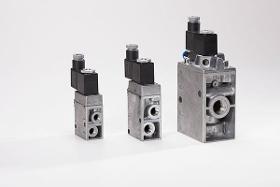

Solenoid Valve EMV Nom.width (mm) Flow rate (l/min) Control 10 ... 25 430 ... 1.200 24 V DC / 230 V directly-controlled vacuum valve to control suction circuits

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Solenoid Valve EMVK Nom.width (mm) Flow rate (l/min) Control 2 ... 4 200 ... 400 24 V DC directly-controlled pneumatic valve for control of suction circuits or ejectors

Request for a quote

ALBERT FEZER MASCHINENFABRIK GMBH

Germany

Solenoid Valve PEMV Nom.width (mm) Flow rate(l/min) Control 5 ... 19 150 ... 1410 24 V DC pneumatically controlled vacuum valve to control one suction circuit

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Valve-Tronic Plus™ is designed for use in highly demanding industrial applications that require accurate flow control and measurement. It can function as a stand-alone controller for basic applications or become an integral part of a process control system for automatic flow control. FEATURES • Large LCD displays actual flow rate, totalized flow, valve position, alarms, and diagnostic messages • Field programmable engineering units • Magnetic sensor technology immune to problems related with dirty oil • Configurable to control based on rate of flow or valve position for applications where the Process Variable (PV) is Dew-point, Carbon Potential, etc. • Standard Modbus TCP for easy integration with control systems • Manual actuation of value possible • Field calibration for null and span • Advanced polynomial calibration for high accuracy over the entire range of the meter • Built-in Web Server with remote access to device • Full PID setpoint control The VALVE-TRONIC Plus™...

Request for a quote

EM-TECHNIK GMBH

Germany

The fine control valve regulates even the smallest flow rates with great precision and with linear flow rate characteristics. Different spindle types are exactly matched to the media and the flow range. Additional safety and reliability are achieved by the spindle thread outside the media flow.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The system is a fully computer controlled unit of turn key design, and ready for use after installation and commissioning. It is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector with 20 receivers includes a builtin internal balance for the determination of the fraction weight, while the separate volume follower system is used for discharging the fractions into the final receivers and the determination of the fraction volume as well as for the direct distillation rate control. The vacuum equipment and the control system are designed for highest accuracy, repeatability and reproducibility of data. Numerous optional items available.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D5236 CC / FISCHER® AUTODEST® 860 AC is a fully computer controlled unit of turn key design, and ready for use after installation and commissioning. The system is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector with 12 receivers includes a builtin internal balance, which is used for the simultaneous determination of the fraction weight and for the direct distillation rate control. The vacuum equipment and the control system are designed for highest accuracy, repeatability and reproducibility of data. Also available are the iFischer® DIST D5236 CC 50 ltr, 100 ltr, 150 ltr and 250 ltr fully automated computerised distillation systems acc. to ASTM D5236 equipped with a set of comprehensive safety features in correlation with the applicable EU Machine Directives and refinery standards. Numerous optional items available.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D5236 CC / FISCHER® AUTODEST® 860 AC can be converted to the “HV” version by adding an extended Potstillcolumn to the standard ASTMsystem (Potstill). The respective distillation process is performed in the range of 0.005...0.1 mm Hg. The iFischer® DIST D5236 HV 6 ltr / FISCHER® AUTODEST® 860 HV 6 ltr is a fully computer controlled unit of turnkey design, and ready for use after installation and commissioning. The system is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector with 12 receivers includes a builtin internal balance, which is used for the simultaneous determination of the fraction weight and for the direct distillation rate control. The vacuum equipment and the control system are designed for highest accuracy, repeatability and reproducibility of data. The system is also available with a capacity of up to 50 ltr.

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

Welbee W400: Precise adjustment and arc stability – even in the lower welding area* Precise adjustment of energy input due to AC pulse welding process * High-speed AC pulse welding due to improved features for the respective material * Welding shape looks like TIG welding process due to AC wave pulse technology * High melting rate, weld penetration control * Extended application scope due to 400 A at 40% rated duty cycle

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

laserXtens Array HP features a measuring head incorporating seven fixed high-resolution cameras. The overlapping fields of view of the seven cameras are combined into a single large image, giving a very large measuring range.Advantages of laserXtens Array - laserXtens Array HP possesses an extremely large measuring range, combined with a resolution of 0.10 μm. - laserXtens Array HP has no moving parts and is completely maintenance-free. - laserXtens Array HP satisfies the requirements of Class 0.5 of ISO 9513 (Class B2 of ASTM E83). - Used for strain-rate-controlled tests to ISO 6892-1 Method A1 (closed loop) for gage lengths from 30mm. Different gage lengths can be set in fractions of a second. laserXtens Array HP can also measure transverse strain with no need for additional markings; biaxial measurement is additionally possible. Determination of strain distribution and strain at break as per Annex H of ISO 6892-1

Request for a quote

HEXPOL TPE GMBH

Germany

With our Dryflex WS range we have turned the usual water-resistant properties of TPEs on their head to engineer materials that swell up to ten times their volume when immersed in water. Dryflex WS are a range of thermoplastic elastomers (TPE), which contain hydrophilic particles. They swell at a controlled rate and percentage, with swell rates from 300 to 1000% when immersed in water. When there is no longer water present the compound shrinks back to its original size, a process that can be repeated an almost unlimited number of times. Dryflex WS materials are used in applications to form a positive seal and prevent the ingress or exit of water. We have also developed softer grades which offer excellent drapability. They are an ideal choice for water stop applications where the profiles may be coiled or need to be fitted around complex structures. Compounded in any colour, the water swellable TPE is 100% recyclable and can be processed using conventional plastic fabricating methods, i

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

With its VEN SPRAY PERFECT Venjakob has the innovative answer to all requirements encountered on the market. Based on decades of know-how in the realisation of high-performance spray painting plants, it is the flexibility of this new generation that convinces. In the long term, the modular system takes into account all production requirements. At the time of machine purchase, its concept realises all variants, from "one off batch size" through to large series production in the high-end range. The modular concept permits implementation of changing framework conditions at any point in time by retrofitting new modules, thereby making your investment future-proof. Working width: 1,300 / 1,600 / 2,200 mm Working height: 940 mm Feed speed: 3-8 m/min Exhaust air volume: 7,000 - 10,000 m³/h Connection value: 20 KW Machine dimensions: 2,280 / 2,800 mm (length of booth) The sophisticated spray gun control minimizes the rate of overspray. With the patented V-belt design up to 98 % of the liquid overspray can be reclaimed. The paint retrieved in this way is recycled into the paint process. Over and above, the innovative ventilation system improves the ecological energy balance. The short setup times, long service life of the filter elements, fast changing times for spray systems and automated paint-change procedures offer a very high degree of efficiency. The twin cleaning units allow the use of solvent-based paints as primer and the direct switchover in split seconds to the second cleaner operating with water-based paints. Maintenance and cleaning operations take place completely separate from the production process.

Request for a quote

PULSARLUBE GMBH

Germany

The Pulsarlube PLC electromechanical automatic grease lubricator is specially designed to be fully integrated as well as be synchronized to a PLC system .Kindly offers two types of PLC lubricator, Month and Interval type for wider range of usage. Can remotely send a dispensing signal to the lubricator when lubrication is needed Precise lubrication on demand Can lubricate up to 8 lube points (Max. 6m) High output pressure of 30~60kgf/cm² (425~850psi) User can control dispensing rate based on hours of operation of equipment(INTERVAL TYPE)

Request for a quote

PULSARLUBE GMBH

Germany

The Pulsarlube V automatic grease lubricator operates based on the proven technology of electrochemical reaction which generates inert Nitrogen (N2) gas through the systematic use of an electrolyte and electrical energy. Cost effective by reduced inventory Easy to install and simple to operate using one-touch switch Microprocessor controlled accurate dispensing rate Large user friendly LCD Available dispensing periods: 1, 2, 3, 6, 12 months and Purge (P) Immediate grease dispensing available for testing and installation by using Purge (P) mode Transparent container for easy visual inspection of lubricant levels

Request for a quoteResults for

Rate controls - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Water extraction - systems and equipment (4)

- Lubrication equipment and machinery (2)

- Plastics - machines and material for industry (2)

- Valves for pneumatic equipment (2)

- Valves for industrial fittings (1)

- Testing equipment (1)

- Industrial valves, operating equipment (1)

- Plastics - industrial machinery and equipment (1)

- Sealing rings (1)

- Welding, soldering and brazing - equipment and supplies (1)