- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- quality inspection

Results for

Quality inspection - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

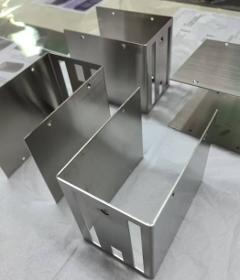

The process of sheet metal processing: Select the appropriate sheet metal, and carry out the necessary treatment and preparation, such as cutting, bending, stamping, etc Processing stage: forming the metal sheet, including cutting, bending, stamping, welding and other process operations Inspection stage: Conduct comprehensive quality inspection and evaluation of the final product, including appearance inspection, size inspection, performance testing, etc

Request for a quote

QUELLTECH GMBH

Germany

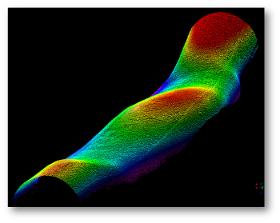

Particular Challenges: In the course of the production, endless cables are running at a considerable speed, and supervision has to be carried out nearly under real-time conditions. The size of the objects to be determined, i.e. of the flaws to be discovered, is in the range of only some hundredths of a mm. Another difficulty is the fact that surfaces with very different reflectivity and roughness are involved. In order to be able to check the cables all around, several laser scanners must be in place, mounted at different angles, thus covering the entire range of 360°. Quelltech Solution: The solution consists in a configuration of four Q6 laser scanners, mutually displaced by 90°, so the entire surface of the cables is in the field of view. On the basis of the 100% inline inspection, the position of defects can precisely be determined, without losing too much time.

Request for a quote

QUELLTECH GMBH

Germany

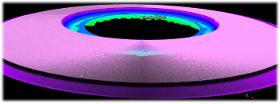

Particular Challenge: For the assessment of rotating parts, numerous parameters have to be taken into consideration: Concentricity, radial run-out and axial run-out (i.e. wobble); furthermore thickness, diameter, planarity and the absence of surface defects had to be examined. The solution developed by QuellTech consists in a configuration of three Q6 Laser Laser Scanners.Each of the lateral surfaces is assigned to its own scanner. In order to enable the thickness precisely to be determined, both laser lines are mutually oriented in opposite direction. The third scanner inspects the outer circumference of the wheel, this way measuring diameter and radial run-out. All of these scanners are subject to encoder signals supplied by the rotary axis and synchronously triggered, so possible defects on the wheel can precisely be localized. The measurement takes place at a resolution of ca. 30 µm, and a cloud comprising several millions of points are obtained.

Request for a quote

MICRO-EPSILON

Germany

3D laser scanners for inline quality inspection The scanCONTROL 3D scanners are used for inline 3D scans with high accuracy.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Customised system or individual part solutions are our core competence at KIS. We develop complete solutions for you based on our own KIS products and combine them with our comprehensive service for drive technology. Whether it's a careful selection of individual components or proper assembly ensuring your application functions perfectly: As bearing specialists based in Germany, we’re there for every step of the process, from development and construction, through monitoring of production and assembly, to quality inspections and practical tests.

Request for a quote

COMET YXLON GMBH

Germany

The YXLON UX20 system for X-ray and CT inspection of medium to large cast parts makes inspections easier than ever. The award winning user interface Geminy enables an easy inspection, both for your 2D and 3D inspection needs. Our efficient workflows with automation, wizards and presets guide the user. From novice to expert, all levels will discover intuitive controls. The operator makes consistent inspection decisions with our optimized image chain. It combines x-ray tube, detector and image processing providing benchmark image quality. Easy inspection is the sum of many parts. The operator desk, for example, has the absolute essentials you need. You can also vary the height of the desk to accommodate operation from a sitting or standing position. A number of options and upgrades offer possibilities to let the system grow with the demands of the operator. This ensures that the investment is future-proof and benefits from technical advancements for a lifetime.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

This special Metzner development is able to process cable wires with a diameter of up to 28 mm. The cycle time for this is 2000 mm / 35 seconds. The processing steps include long slitting, sawing, circumferential cutting, stripping, brushing and depositing. An integrated ink jet printer labels the cable wires with information or markings. As the heart of the processing method, Metzner uses a newly developed stripping head that combines a rotary cut with a powerful clamping and simultaneous rotation of the material. This enables a high-precision, multi-stage radial cut through the various layers of material. Microscopic quality inspection confirms that the processing is flawless with no scratches, pressure or abrasion marks. In addition to the high machining quality, the machinery also offers special precision: both the overall length and the machining position are maintained with an accuracy of 0.2 mm. The machine can process cable wires with diameters up to 28 mm.

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

Vibrating tables suitable for testing and quality inspection of sensitive components The vibratingsystems are employed for simulation of stress created by mechanic vibrations on mechanical and electrical components and subassemblies with the following features: Direction of oscillation: linear - horizontal (sinusoidal oscillation), adjustable by means of a selector. Either oscillation in x-axis or alternatively in y-axis

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

The range of external vibrators from Knauer Engineering includes normal frequency, high frequency and oscillating vibrators in various executions for applications in the construction and concrete industry as well as in other industries. Besides the proven vibrator system of Losenhausen, Knauer Engineering also offers now a considerably vibrator program for multi-purpose working areas. Applications are used in Construction industry, Industry of building materials, Mining-, Chemical-, Packaging and food industry, mechanical engineering as well as quality inspection and quality assurance.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Inspection of Surfaces 2D and 3D Regarding surface quality inspection for metal products such as cylinder head, gear tooth, it consumes a lot of time and human resources for the inspection. Since parts are inspected by bare eyes or slow speed inspection machines. With the inspection machine HE1000, inspection is much faster, more accurate and fully automated. In addition, there is a 3D laser sensor combined with our 2D inspection head to provide the most accurate result. This sensor is the first in the world to apply the Nobel Prize winning physics technology of optical frequency combs. It utilizes coaxial lasers and high precision range finders. There are some cases that our customers reduced over 90% of the inspection time. urthermore, if parts are inspected by humans, there might be different results by each person, because each of them has a different tendency and criterion.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Visual Inspection of Surfaces This SE1000 Visual inspection measuring machine has been developed to automatically inspect the appearance of dirt, scratches, and other imperfections on various kinds of surfaces of your product. This 2D inspection technology can be used in production lines and is suitable for all kinds of industries that want to improve quality, reduce human involvement in inspection and reduce inspection time. Leveraging this fast, precise inspection machine will help you to improve the quality of your product dramatically.

Request for a quote

SHINING 3D TECHNOLOGY GMBH

Germany

AutoScan Inspec is a fully automatic desktop 3D inspection scanner that innovative integrates highaccuracy 3D scanning and 3D inspection. Featuring intuitive user interface, easy operation and AI intelligent scanning algorithm, AutoScan Inspec offers fully automatic scanning experience with metrologygrade accuracy and fine detail. Designed for scanning small and complex parts, AutoScan Inspec can be applied in inspection and quality control, reverse engineering, product design and etc. Watch the video here.Metrologygrade Accuracy Advanced bluelight 3D scanning technology brings users the scan accuracy within 10μm to ensure high level of accuracy required by quality inspection.

Request for a quote

SHINING 3D TECHNOLOGY GMBH

Germany

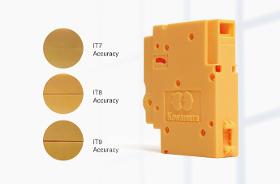

A highprecision resin 3D printer that improves prototyping efficiency and shortens the new product development lifecycle.Unparalleled Accuracy Accurate Precise IT7 level printing accuracy, to ensure the printing size is consistent with the design size. Outstanding Uniformity High luminance uniformity achieves up to 90%. Beyond the Limits Provides not only the possibility to obtain features, smaller than a pixel, but also superior surface finish.StateoftheArt Robustness AccuFab L4K’s 5 million layers tested in real engineering condition provides state of the art reliability. District Cooling System DCS (District Cooling System) maintains the temperature of optical system under 40℃, while extending the 3D printer lifespan significantly. Industrial Grade Components and Quality Inspections Assembly production adopts industrialgrade components, passed 21 strict factory inspections, to ensure the high quality of the factory equipment.

Request for a quote

WECKERLE MACHINES

Germany

Lipstick Filling and Processing Line The L 1800 is a sustainable and economical solution to serve all types of manufacturers of cosmetic products. The very compact L 1800 is able to produce up to 1.800 lipsticks per hour in 24/7 operation. Furthermore, the machine can be upgraded very cost-efficient for producing top filled products such as lipgloss, making it our most compact multi-functional machine available. Features: Weckerle Soft Mold Lipstick Molding Technology, Ergonomically comfortable machine with simple and intuitive handling, Small footprint enables highly efficient use of workspace, Innovative quality inspection camera

Request for a quote

GEBR. RETTBERG GMBH

Germany

Motic Microscope BA310 MET - Advanced Microscope for Industrial & Materials The BA310 MET series is the ideal microscope for industrial quality inspection or materials science Different alternative stand options allows also applications in brightfield or examination of larger samples BA310 MET Trinocular Infinity Optics [CCIS®] Observation Tube Trinocular 30° (Light split 100:00/20:80), F.N. 20 Interpupillary distance 48-75mm Widefield high eyepoint eyepieces N-WF10X/20mm with diopter adjustment on both eyepieces and rubber eyecups Reversed quintuple revolving nosepiece CCIS Plan Achromatic objectives 5X, 10X, 20X, 50X Coaxial course and fine focusing system Mechanical stage 180x140mm, hard coated with built-in low position coaxial stage control Epi-illuminator 12V/50W quartz halogen with integrated field and aperture diaphragms and external lamphouse Power supply 115-230V (CE) Ø 32mm blue, green, yellow and frosted filters, power cord, Allen hexagonal key, vinyl dust cover

Request for a quote

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

InfraCam® of the manufacturer FlirSystems® is with only 550g very light and easy to operate. It is suitable for indoor and outdoor. Through precise high resolution of InfraCam® slight temperature differences are recognized clearly. A high quality, cost-effective inspection device with an operating time of seven hours. Over 50 years experiences in development and production of infrared cameras influenced the development of this new revolutionary model. Rapid developments in detection technology enabled to a small, compact, easy to operate and extremely favourable diagnostic tool. This technology that was so far in high-end infrared cameras and only accessible for limited users, is now open up to a larger circle of users thanks to InfraCam®. Now, InfraCam® produces and saves infrared pictures, which can be easily analysed due to updated software "ThermaCam QuickView". This software is included in delivery of scope of InfraCam®! Datenblatt

Request for a quote

POLIFILM GMBH

Germany

POLIFILM surface protections films have been successfully used for the protection of decorative laminates for decades. Depending upon the gloss level of the laminates low adhesion level films (for high gloss surfaces) or higher adhesion films (for rougher finishes) are used. Typically transparent films are used as they allow quality inspection of the decorative surface without a need to remove the films for this process. For 2D and 3D applications with special requirements we offer several solutions. Co-extruded, uncoated protection films present a good solution for these requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Quality inspection - Import exportNumber of results

18 ProductsCountries

Company type

Category

- Surface inspection systems (3)

- Light-emitting diode LED (2)

- Machine vision system (1)

- Mechanical engineering - custom work (1)

- Bearings - ball, needle and roller (1)

- Cosmetics industry - machinery and equipment (1)

- Foundries - machinery and installations (1)

- Measurement equipment and instruments - position and distance (1)

- Sensors (1)

- Sheet metal and strips, tinplate (1)

- Testing of products and materials (1)

- Vibrators, industrial - installations (1)