- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pure metals

Results for

Pure metals - Import export

EWG E. WAGENER GMBH

Germany

The grey shiny niobium is not unlike tantalum, which also has a very high melting temperature. A striking difference to tantalum is its much lower density. The pure metal is easy to process due to its low hardness. However, it becomes much harder and more brittle due to minor carbon impurities. Niobium is a relatively base element. When exposed to air, a protective oxide layer forms around the metal, which protects it from further corrosion and provides additional resistance. These wafer-thin oxide layers on the metal surface cause the coloured iridescence that occurs when heating a compact piece with a burner. Niobium powder is pyrophoric and can therefore ignite by itself. Glowing niobium powder reacts with oxygen to form niobium(V)-oxide. The compact metal resists most acids at room temperature. After heating, however, almost all acids are able to decompose the metal.

Request for a quote

EWG E. WAGENER GMBH

Germany

Zirconium is a silver-grey, shiny heavy metal. In its pure form it is easy to work, corrosion resistant even at high temperatures and has a very low neutron capture cross section. In addition, zirconium offers good stability against structural damage caused by neutron irradiation and against cavitation by coolant flows. The metal is mainly used pure or alloyed with 1.2-1.7% tin, for corrosion resistant pipes, fittings and valves in the chemical industry. This special alloy is called Zircaloy. Zirconium plays an important role in reactor construction. It is used for fuel element claddings and holders, for the pressure vessel lining, and for all structural components that come into contact with neutrons. In the rocket and jet aircraft industry zirconium is used for the manufacture of combustion chambers and feed lines. In electron and X-ray tubes zirconium is used as getter material.

Request for a quote

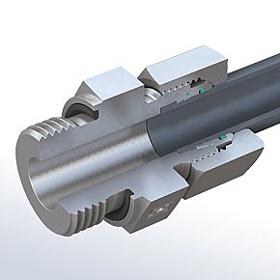

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Soft-Sealing Cutting Rings provide an additional safety and protection against potential leakage risks, e.g. caused by the settling of purely metallic sealed connections, temperature fluctuations or considerable pressure and vibration loads in the system. "Sweating effects" on the connection points can be permanently avoided. The type FI-WDDS Soft-Sealing Cutting Ring of the STAUFF Connect range is characterised by the elastomer sealing, which is located in a specially designed groove close to the rear end of the 24° taper and protected to prevent loss. An additional o-ring is used to secure the secure the second potential leakage path between the cutting ring and the tube – even in the event of unfavourable tolerances FKM/FPM (Viton®) is used as the standard sealing material and enables problem-free use of the system for challenging applications involving high temperatures or aggressive media. Like all other components in the STAUFF Connect product range, the cutting ring...

Request for a quote

MECHASYS GMBH

Germany

Electrical Steel: rotor and stator sheets as full service Due to the growing demand for electrical steel, we have bundled our technological resources and expanded the production of pure sheet metal blanks to complete packages in stator and rotor sheets. We are therefore able to provide you, our customers the service of complete sheet metal stacks baked, laser-welded or punched packaged in the electrical steel sector. Due to our extremely thin cutting gap of just 0.07mm - as much as the diameter of a human hair - we are able to produce the smallest contours. The extreme power density at a max. laser power of 1,000 watts enable electrical sheets based on baked varnish technology with the lowest possible edge zone melting - burr-free. Everything 100% "Made in Germany" in packaged quality - usually tolerance class T7. Usual delivery times are approx. one week for cutted sheets, 2-3 weeks for baking or welding parts. Let’s get in contact for your new e-drive, rotor or stator!

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

VSG systems offer a poven and economic solution for the inductive melting of metals or alloys under vacuum or protective gas atmosphere and subsequent casting. Applications: The VSG furnaces can be universally employed for melting and casting under high vacuum or different gas atmospheres in the laboratory or production, e.g. alloying, degassing, purification melting, re-melting processing of noble metals highly pure, highly alloyed steel. • Processing of: ◦noble metals ◦ processing of highly pure, highly alloyed steel ◦ High temperature resistant materials on Fe- Ni- Co- basis ◦ Solar-silicon and other special material ◦ Special- / super alloys

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HARTMANN VALVES GMBH

Germany

The Hartmann Twin Ball Valve (TBV) provides a double line barrier and enables a significant increase of safety without much effort. Designed for applications with especially high safety requirements, the TBV consists of two integrated ball valves, which can be equipped with two independent barriers each. Thereby the safety can be raised by factor 4 compared to a standard valve. With the Double Isolation and Bleed function each ball valve seals both at the upstream and downstream side. With the so-called „studded“-design, meaning a closed flange form, the valve has the length of a single standard valve and affords a compact and economic alternative for the application of multiple valves. The TBV comprises – like all Hartmann valves – a pure metal-to-metal sealing system between ball and seat ring. With this sealing system leakage rates A, respectively 0, can be fulfilled. Furthermore, it is characterized by an outstanding longevity and low maintenance requirements.

Request for a quoteResults for

Pure metals - Import exportNumber of results

7 ProductsCountries

Company type