- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- punch cutting

Results for

Punch cutting - Import export

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For short, straight and figure cuts, small radii • Cutting edge hardness 57-59 HRC • Cutting edges inductively hardened • Re-adjustable screw-joint • Handles coated with plastic • Made of tool steel, forged, oil-hardened

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

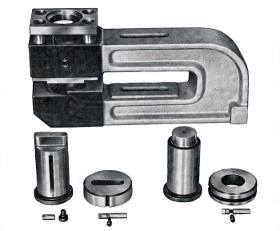

Punching units Punching unit with exchangeable cutting elements for sheets and profiles up to a material thickness of 25.0 mm and a hole diameter of 150.0 mm JOKA punching units consist of a special cast stand that accepts the punch and die and ensures the exact axis alignment between the cutting elements (punch and die). In addition, there is a stripping system in the upper part of the tool stand, as the material wipes off automatically after punching. The scraper contains two or more disc spring packages that guarantee perfect scraping even in the border areas. A fixed connection between the tool and the upper part of the press is therefore not required. To determine the exact position, each tool has a positioning pin (two for shaped holes) on the underside, which is precisely aligned with the cutting elements (center of the hole). The above picture shows a complete punching unit without cutting elements and one cutting set (punch and die) each for round hole or shaped hole.

Request for a quote

BRUNO UNGER GMBH & CO KG

Germany

For cutting, perforating or punching of foil and paper products

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

J57S UP is a rolled alloy designed to be a perfect base material for batch anodized aluminum. Created specifically by Novelis to meet the requirements of modern architecture, including aluminum facades and aluminum roofing, its value and utility have been proven over decades of use. Its excellent deformation capacity provides the best preconditions for fabrication, allowing for bending, cutting, punching, drilling and more.

Request for a quote

J.D. GECK GMBH

Germany

Our competences ,Flexible and toolbased sheet metal processing ,2D laser cutting, punched and folded parts. ,Bent wire parts madetomeasure ,Manual and automated welding. We would be happy to manufacture your preliminary products. More information available at https//www.geck.de

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Drop lubrication of cutting tools at machining work on ferrous and non-ferrous metals, for example during drilling, thread cutting, sawing, milling, punching and nibbling Advantages and benefits Reduces friction and required force Permits high continuous load and higher cutting speeds Allows optimal cutting surfaces Extend tool lives through reduction in wear Neutral behaviour toward machine coatings Free of chlorine and heavy metals Low tendency to form oil mist OKS 390 is suitable for use with the OKS Airspray system Also available as spray version OKS 391Apply a sufficient quantity of OKS 390 to the tool or machining point using a brush, drip oiler or oil can. Spray on sufficiently OKS 391 spray. After use OKS 390 can be removed with OKS 2610/OKS 2611 universal cleaner. Caution: Check compatibility before using on non-ferrous metals.

Request for a quote

KW HYDRAULIK GMBH

Germany

Bus Bar Working Stations for Bus Bars and Flat Material Punching Tools for Bus Bars and Flat Material Cutting Tools for Bus Bars and Flat Material Bending Tools for Bus Bars and Flat Material Brochure Tools for Control and Switchgear Cabinets Tools for Laminated and Flexible Bars and Earthground Sheet Metall Hole Puncher DIN Mounting Rail Cutting Devices Wiring Duct Cutting Tool Punching Tools for Sheat Metall

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Drop lubrication of cutting tools at machining work on ferrous and non-ferrous metals, for example during drilling, thread cutting, sawing, milling, punching and nibbling Advantages and benefits Reduces friction and required force Permits high continuous load and higher cutting speeds Allows optimal cutting surfaces Extend tool lives through reduction in wear Neutral behaviour toward machine coatings Free of chlorine and heavy metals Low tendency to form oil mist Apply a sufficient quantity of OKS 390 to the tool or machining point using a brush, drip oiler or oil can. Spray on sufficiently OKS 391 spray. After use OKS 390 can be removed with OKS 2610/OKS 2611 universal cleaner. Caution: Check compatibility before using on non-ferrous metals.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

When processing sheet metal parts by punching, lasering, plasma cutting, flame cutting, etc., a burr is always created. We have met the challenge of deburring or rounding these “sharp” edges of the workpieces in companies by developing our deburring grinding wheels and deburring rollers. By using these highly flexible tools, both on hand machines and on automatic machines, sheet metal parts can be optimally rounded or deburred. We have the right dimensions for your deburring machine! We would be pleased to advise you on which deburring rollers can be used in your processing, in order to achieve top process results.

Request for a quote

BÜRKLE GMBH

Germany

The drill head for carcass sampling has a hexagonal socket for bit holders or chucks, suitable for all commonly used cordless screwdrivers or drilling machines. Meat sampler for microbiological sampling of carcass surfaces. Slaughtering businesses (slaughterhouses, butcher's shops, etc.) are obligated as part of operational process control and for monitoring of slaughter hygiene to conduct regular microbiological examinations of carcasses for cattle, hogs, sheep, goats and horses, etc. The samplers for carcass sampling are similar to a cork drill. They can be used in the punch process (a destructive process, also called the cork drill or excision process) to remove a circular sample of tissue of 5 cm² from the surface. After the punch sample is cut out, it is removed from the carcass with a scalpel and tweezers.

Request for a quote

HFP BANDSTAHL GMBH & CO KG

Germany

Cold rolled strip is used in a variety of applications. It meets high demands on forming behaviour, dimensional tolerances and surface finish, which offers our customers decisive advantages! HFP cold rolled strip is ideally suited for all stamping, bending, drawing and deep drawing purposes. From ball bearing housings to roll cutting and punching strips, hose clamps, headlight reflectors, electrical equipment, office supplies and tubes to safety parts of all kinds, a wide variety of components can be manufactured for various industries. DC 01, DC 03, DC 04 according to DIN EN 10139 / mild steel - St 37/ special grades on request Depending on the customer's requirements, we supply treatment states from LG to C690.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

The consistent high quality of B57S makes it an excellent choice of anodising quality aluminum. It is designed for many different applications including electronic covers, in the transport and automotive industries, road and advertising signs and equipment housings. Your selection of material is of utmost importance. Finding a high quality product, with a good price/performance ratio, B57S will meet your needs. B57S can easily be cut, drilled, punched, edge-flanged and formed. Welding and brazing should be avoided in visible areas, because the localized heating of the metal will change its structure and affect the anodized finish.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Labelling systems can be integrated, whether it is laser, needle or inkjet, to mark and identify the tubes. Other options that can be integrated are welding seam detection, length control or measurement of processed tubes. The corresponding sensor and camera technology can be implemented for the specific product. The following step can be carried out without any problems, whether it is cutting, punching, deburring of holes or seal testing with external systems. Smart data evaluation All the systems can be equipped with different control and IPC panels. Interfaces to data caption systems for consumption and operation make the digitalization and evaluation of the data. Marking system, Welding seam detection, Camera control system, Internal and external cleaning processes, Cleaning and suction, Hole punching, Deburring – chamfering

Request for a quote

EFFBE GMBH

Germany

Our excellent reputation motivates us to tackle new challenges every day With the qualities EFFBE 295 and EFFBE Urelast®, EFFBE sets new standards in the service life and settling behavior of elastomer springs. Our elastomer springs stand for many years of permanently elastic and unbreakable use, for example in cutting and punching tools. Our customers around the world appreciate the quality of the EFFBE product ranges, which also offer a favorable price-performance ratio and high cost-effectiveness due to zero maintenance. Awareness of our excellent reputation motivates us to tackle new challenges every day. That's why our engineers and designers develop customized parts for you, if our standard ranges are unable to solve your problem. Elastomer compression springs are regulated by the standard DIN ISO 10069-1. Our qualities EFFBE 295 and EFFBE Urelast® meet this DIN standard and even surpass it in terms of service life and settling behavior.

Request for a quote

NWS GERMANY PRODUKTION W. NÖTHEN E.K.

Germany

• For short, straight and figure cuts, large radii • Cutting edge hardness 57-59 HRC • Cutting edges inductively hardened • Re-adjustable screw-joint • Handles coated with plastic • Made of tool steel, forged, oil-hardened

Request for a quote

MECHASYS GMBH

Germany

Laser welding is a very gentle welding technique, as the heat input takes place in a locally very limited area. In this way, it is possible to reliably connect critical components with one another in a materially bonded manner, without the parts annealing. With laser welding, the two welding partners are joined together with as few gaps as possible in order to then weld them together (e.g. press-fit zones such as EloPin® puzzled at any feed or distance). The background to this is that no additional material is generally used in laser welding. Exception for build-up welding or repair welding of e.g. broken tool parts such as punches or cutting plates or injection molding tools for abrasive plastics with glass fiber filling. Materials - almost all metals: e.g. • non-ferrous metals (Cu, CuSn0.15, CuSn6, CuNiSi, ...), • titanium, • steel, stainless steel (1.4301, 1.4404, ...), • spring steel (1.4310), • electrical steel (M235, M270, NO20, NO30, ...), …

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming and scoring hidden airbag compartments on thermoformed skin. After the fabrication of IP skins through thermoforming, two separate fabrication steps are still needed before foaming. In the first step, the thermoformed skin will be trimmed in the external zone through punching or a blade cutting process. Depending on the requirements, this is where FRIMO's blade cutting equipment comes into operation. In the second step, the skin will be weakened in the airbag area by a blade. By using the new FRIMO FlexTrim Combi Trim Scoring machine, both steps can be realised at once. The skin is positioned in a common component fixture and finished with two different cutting tools. The new system concept, with its flexible design and layout possibilities, offers a variety of options for combinable process and operation groupings. As an example : one 2-station system with two robots, which are equipped with automatically exchangeable cutter heads, and where two different products

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WINTERHOFF PICARD GMBH

Germany

We develop precision-cut knives for a wide variety of foils. Irrespective of whether the foils are extra thin, unusually thick, viscous or elastic, or whether they are shrink-wrapped, printed, finished, environmentally friendly or else biofoils - we supply the best knives.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Cutting, punching, perforating, folding and register cutting are among the most important work steps in the production process. These are the main tasks of our knives – used in a wide variety of ways, for applications on various types of machines. With excellent repeat performance and optimally protected against wear and tear, for highly profitable knife inserts and tool life.

Request for a quoteResults for

Punch cutting - Import exportNumber of results

44 ProductsCountries

Company type

Category

- Knives, industrial (15)

- Lubricants, industrial (3)

- Punching machine tools (2)

- Metal industrial presses (2)

- Building hand tools, non-power (2)

- Silicones (2)

- Aluminium sheets and bands (1)

- Anti-vibration supports (1)

- Cold rolled steel strips (1)

- Grinding - steels and metals (1)

- Laser - cutting and welding machines (1)

- Packaging (1)

- Pipes and tubes - ferrous metal (1)

- Quality control and certification (1)

- Rubber seals (1)

- Screen printing for advertising (1)

- Seals (1)

- Steel & Metals (1)

- Structures, aluminium (1)

- Ultrasound systems - Processing plastics (1)