- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ptfe coating

Results for

Ptfe coating - Import export

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication of most different materials sliding on resp. rubbing against each other like metals, wood, ceramics, rubber as well as paintable plastics For packing machines, sliding areas in the plastics and textile industry, rollers and chutes in the transport range, etc. Non-stick coating of all kinds of sealings and sealing areas to avoid sticking, squeaking of soft on hard materials (e.g. rubber on glass), for water-repellent impregnation of absorbing materials or as separating film for casting resin applications Advantages and benefits Thin, tack-free separating film with very good adhesive properties on prepared surfaces Best suitability for low-friction lubrication of all kind of materials in contact Colourless and odour-free antifriction coating with non-stick properties

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication of the most varied materials sliding on top of or rubbing against each other (such as metals, wood, ceramic, rubber, and also adhesives or paintable plastics) Anti-stick coating of seals or sealing surfaces of all kinds to prevent sticking-on To cure the squeaking noises of soft on hard materials For water-repellent impregnation of absorbent materials Separating film in cast resin applications Advantages and benefits Dry, non-soiling film Highly effective due to good adhesion to prepared substrates Colourless and odourless low-friction coating with non-stick properties Prevents frictional corrosion Dries at room temperature

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication of the most varied materials sliding on top of or rubbing against each other (such as metals, wood, ceramic, rubber, and also adhesives or paintable plastics) Anti-stick coating of seals or sealing surfaces of all kinds to prevent sticking-on To cure the squeaking noises of soft on hard materials For water-repellent impregnation of absorbent materials Separating film in cast resin applications Advantages and benefits Dry, non-soiling film Highly effective due to good adhesion to prepared substrates Colourless and odourless low-friction coating with non-stick properties Prevents frictional corrosion Dries at room temperature Also available as spray version OKS 571

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication with solid lubricants for long-lasting efficiency at low sliding speed and with high surface pressure Long-term lubrication with excellent protection against wear for increased service life of slide areas Fully effective even after longer downtimes; no adherence of dust and dirt Advantages and benefits High-strength long-term antifriction bonded coating with high efficiency through good adhesion on prepared surfaces Constant friction value of the sliding film even under extreme load Increased protection against wear of otherwise not accessible slide areas

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing Stainless steel / PTFE coated | Maintenance-free dry sliding bearing | Corrosion resistance | Chemical resistance | DIN 1494 / ISO 3547 NOX-MET® is a versatile, corrosion-resistant dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, additional lubrication is possible in principle! Excellent sliding and wear behaviour, high load capacity, shock resistant, chemically resistant against acids and bases (ph-value 0-14), corrosion resistant. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing steel / Special PTFE coated Maintenance-free dry sliding bearing | DIN 1494 / ISO 3547 TEF-MET/P is a versatile dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, it is very well suited for lubricated applications (e.g. hydraulic oil lubrication). For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Wrapped composite plain bearing steel / PTFE coated | Maintenance-free dry plain bearing | DIN 1494 / ISO 3547 TEF-MET is a versatile dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, additional lubrication is possible in principle! Excellent sliding- and wear behaviour, for all types of movement, high load capacity, all-round adaptable. For technical details, please visit the product page on our website!

Request for a quote

GLT BEARINGS GMBH

Germany

Rolled composite plain bearing steel / PTFE coated | Maintenance-free dry plain bearing | DIN 1494 / ISO 3547 TEF-MET/B is a versatile, corrosion-resistant dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, additional lubrication is possible in principle! Excellent sliding and wear behaviour, for all types of movement, high load capacity, good corrosion resistance, non-magnetic. For technical details, please visit the product page on our website!

Request for a quote

STOTTROP-TEXTIL GMBH & CO KG

Germany

This glass fiber fabric or facade fabric is coated with a Teflon coating . The chemical term for Teflon is PTFE. The unique properties of Teflon are already known from many other applications , e.g. the incomparable dirt repellency and the high stability against environmental influences. Due to these properties, the PTFE MESH glass fabric is the perfect material for your building envelope . A facade concept with which building structures can be marketed much more attractively. In the textile PTFE MESH fabric, we combine very strong glass fibers to form a defined, non-flammable mesh and encapsulate the fibers with a special PTFE coating . These Teflon fabrics are stretched over frames that are hung in front of the building's facade . The hole size can be chosen so that it is easy to look through the facade from the inside of the building . From the outside, the building appears as a light and clear surface.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE inductive sensors for high mechanical loads still work trouble-free even after 10 impacts of 8 Joule. The sensor protected by a solid stainless steel sleeve is thus particularly resistant to shock and vibration. They are ideal for areas where standard sensors could be damaged mechanically. EGE offers variants resistant to high pressure cleaning with protection class IP 68/IP69 for use at temperatures up to 110° C and contamination-resistant sensors with PTFE coating. The proximity switches are based on the proven inductive principle and switch con tactless when a metallic object moves close. The sensors are particularly suited for heavy duty use, for example in metal processing, during welding and in mobile machinery.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Strong crimped plug/cable attachment Circular cable cross section to reduce kinking and twisting Various cable lengths available Types: MicroMag surface + air thermocouples Easy to place, ideal for difficult-to-access car body shell areas Encapsulated magnet design allows reliable direct use even on wet painted and e-coated substrates IRMAG surface thermocouple Designed to measure ferrous substrates in IR cure ovens Robust alternative to Adhesive Patch thermocouple, combines easy attachment and fast thermocouple response Magnetic surface + air thermocouples Magnet offset from sensor prevents heatsink effect PTFE handle for easy removal or repositioning PTFE-coated to prevent sticking Aluclamp surface thermocouple Clips onto the edge of an aluminum car hood or other nonferrous panel Allows measurement of surface temperature at center of panel Aluminum automotive thermocouples with a spring-loaded bobbin for use on aluminum car body shells

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Designed to be accurate, repeatable, and easy to operate IEC584 color standard (green) for type K thermocouples Strong crimped plug/cable attachment CLAMP thermocouples clip to non-ferrous components Clamp Surface for measuring substrate temperature Clamp Air for measuring ambient temperature ADHESIVE PATCH thermocouple Ultrafast response, single strand and PTFE coated Minimal thermal mass – ideal for small items or plastics EXPOSED-JUNCTION thermocouples for use on test pieces that are left permanently rigged Attached to the substrate by spot welding, soldering, use of high-temp tape or screw EXPOSED-JUNCTION THERMOCOUPLE – HIGH-TEMPERATURE featuring a glass-fiber cable Attached to the substrate by high-temp tape or screw, or spot-welded into position Placed at critical points on the product, thermocouples enable temperature profiling with a DATAPAQ Oven Tracker. All DATAPAQ probes conform to the highest standards and provide the most accurate data possible.

Request for a quote

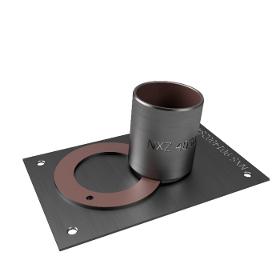

KROHNE MESSTECHNIK GMBH

Germany

Sensor with flange and extention tube The TRA/TCA-F13 is a flange temperature assembly. The main field of application is in tanks or pipelines and a weld neck flange is used to connect them; the particular advantage to this type of thermometer is that they can be coated (e.g. with PTFE), making them resistant to aggressive media. Form acc. DIN 43772: Form 2F Design: DIN-style, welded, multipart thermowells Process connection: flanges: DN25/PN40, DN50/PN40, ANSI 1/2", 1" and 1 1/2", 150 and 300 lb Neck tube connection: with fixed neck tube Tip design: straight tip Diameter: Ø 9, 10, 11 and 12 mm

Request for a quote

BRUKER OPTICS GMBH & CO. KG

Germany

10 cm optical path length for the identification and quantification of high gas concentrations Volume inside the gas cell is 25 ml only PTFE coating of the gas cell enables the measurement even of corrosive gases Accounts for variable pressure and temperature of the gas by sensors The MATRIX-MG01 features a gas cell with 10 cm optical path length and is especially well suited for the quantification of gas compounds with very high concentration. The cell has a volume of 25 ml only to enable a fast gas exchange with minimum gas consumption. Its PTFE coating and ZnSe windows ensure a maximum corrosive protection. The MATRIX-MG01 is equipped with temperature and pressure sensors and their measurement values are automatically read out and considered within the control software OPUS GA.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

For temperatures up to 450 °C. High-temperature furnaces Tempering furnace for car chassis stabilisers Previously cold-formed workpieces, e.g. stabilisers, are heated up in the tempering furnace at circulating air temperatures of up to 450°C and maintained at this temperature for an adjustable dwell time. This tempering increases toughness and dissipates residual stresses. Preheating furnace for frying pans and roasting tins Pan blanks are heated up to a temperature of approx. 390 °C and burnt free of all grease and oil residues. Enamelling furnace for frying pans and roasting tins The PTFE coating sprayed beforehand onto the frying pans is baked on at a temperature of approx. 450 °C. PTFE is used as a non-stick coating for frying pans and cooking pots on account of its low surface tension and good heat resistance. Chamber enamelling furnace for aluminium sheet metal forms Baking on of the single or multi-layer PTFE coatings at approx. 450 °C.

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Technical specifications • threads G 3/4A, ¾” NPT (wrench size 32mm) • accuracy ± 3mm or 0,03% of measured distance (reference conditions see product information) • repeatability <2mm (reference conditions see product information) • application temperature according to design -40°C to +150°C • Druck -1 bis 40 bar Variants • single rod probe / optional: PTFE coating • wire rope probe • coaxial probe • standard or Ex version

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre compressed Packing set of expanded graphite with Inconel Matrix reinforcement and special PTFE coating Characteristics Ring Set made from special high temperature resistant yarn and pore filling cross section impregnation fulfills with a tested leakage rate of 8.4 x 10 -3 mbar · l/(s·m) the leakage criteria of VDI 2440 +400 °C with a maximum allowable leckagerate of 1 x 10 -2 mbar l/(sm) and is suitable for temperatures up to +300 °C. Operating range Pressure without LiveLoading: p 40 [bar] Pressure with LiveLoading: p 100 [bar] Temperature without LiveLoading: t +300 °C Temperature with LiveLoading: t +300 °C pH: 0 - 14 Main application Valves Flaps Gate valves Fittings Control Valves Suitable for Power plant technology Chemical industry Petrochemical plants Boiler houses Approvals TA Luft / VDI 2440 Certificate ISO 15848-1 CC1 ISO 15848 test was conducted with 20,000 mechanical cycles and 2 thermal cycles (RT, +200 °C) and passed with a leckagerate of 6.1 x 10 -4 mg/s/m.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Ptfe coating - Import exportNumber of results

18 ProductsCountries

Company type