- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- prototyping

Results for

Prototyping - Import export

CIC - KLAUS CZERWONKA

Germany

Milling of complex components for automotive and mechanical engineering. Production of prototypes, test parts, small and large series according to data records, drawings, samples or specifications. Machining of cast and forged blanks. Attachment of decorative surfaces.

Request for a quote

MICROCONTROL GMBH & CO. KG - SYSTEMHAUS FÜR AUTOMATISIERUNG

Germany

From the Idea to Prototyping to Series Production and Evolution – MicroControl plans, develops and manufactures individual solutions. MicroControl experts will work in close liaison with the customer to realize hardware and software for the desired application. In a following step, a prototype will be developed and manufactured – either by the customer or MicroControl. In the conceptual stage, the required technical specifications of the customer’s application are checked continually.

Request for a quote

EWOQE GMBH & CO. KG

Germany

Welcome to EWOQE, your specialist for prototype construction. We offer a wide range of services to help you move your development projects forward, including demonstration models, dummy components, and functional parts. We are committed to delivering high-quality prototypes and initial samples, and we take pride in being your reliable partner throughout the process. Our team of experienced professionals works closely with you to understand your requirements and provide customized solutions. We provide model creation services that enable you to verify the design and functionality of your products. Our prototypes are of the highest quality and meet your specifications, whether they involve machine elements, bezels, or complex functional components. We offer rapid turnaround times and cost-efficient solutions to help you achieve your development goals.

Request for a quote

MECHASYS GMBH

Germany

Samples, prototypes and small series made of sheet metal Laser cutting, embossing and bending or punching including electroplating. Prototypes and small series - everything from a single source! We manufacture your individual sample parts, prototypes and small series mostly without any proportionate tool costs. This means that we are very flexible, efficient and cost-effective even with small quantities - in extreme cases from a quantity of 1. This is made possible by our modular bending kit. Everything from a single source: • raw sheets in stock • Laser fine cutting also from pre-punching tape using camera calibration technology • Embossing, bending, folding, pressing • Punching of functional areas • Progressive punching of medium quantities, depending on economic efficiency • Module assembly • CNC laser welding • Complete or partial electroplating by partner.

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

The NDIR bundle medical gases is a test set of perfectly matched components for gas analysis in the medical environment. The bundle offers a selection of IR emitters and detectors for the measurement of common gases such as CO2, CO, N2O, hydrocarbons, halothane, x fluranes or alcoholic compounds: three IR emitters of the JSIR 350 series in different housings and seven matched thermopile IR detectors with two or four channels of the MTS 200 series. Developers thereby achieve rapid results in the project phase: short-term availability of infrared components in small quantities; evaluation and testing of products and various components in one measuring system. Fast test results in the development of medical technology systems and devices help to achieve a significant competitive edge until the series product is ready for the market. Micro-Hybrid is the only manufacturer worldwide to supply both infrared components for gas analysis in one set.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Based on your ideas and in close collaboration with your specialists, PRUFREX takes part in the development of your new products. In the shortest possible time, we are able to supply you with individually produced prototypes and functional models. We use 3D printing technologies to efficiently produce mechanically functional device models. We know how important functionally correct sample products are in the early phases of your product, as are impressions of the look and feel of the device as a whole.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Thanks to our expertise in mechanical production, we can provide you with effective support in the purchase and procurement of: supplier parts Prototypes Experimental parts Rapid prototypes Sample parts You can obtain these parts directly from us from our supplier network, or we will support you in procuring them from your suppliers by coordinating your development, purchasing, logistics and quality assurance.

Request for a quote

EWOQE GMBH & CO. KG

Germany

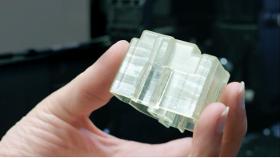

Discover EWOQE's comprehensive service offering in 3D printing for mechanical components and prototype construction! We provide a variety of advanced 3D printing techniques such as FDM, SLS, MJF, and SLA to meet your needs and produce high-precision components. Our experienced team assists in the development and manufacturing of prototypes as well as functional mechanical parts. Understanding the importance of quick iterations, we offer rapid turnaround times to shorten your development cycles and optimize your time-to-market. With our advanced 3D printing technologies, we can achieve complex geometries and fine details to ensure your components meet the highest quality standards. Whether you require prototypes for product development, individual pieces for specific applications, or series production, we have the solution for you. Depend on EWOQE as your trusted partner in 3D printing for mechanical components and prototype construction.

Request for a quote

EWOQE GMBH & CO. KG

Germany

EWOQE is your expert in Rapid Tooling, especially for prototype initial samples. Our comprehensive range of 3D printing processes, including FDM, SLS, MJF, and SLA, offers fast, cost-efficient, and high-quality solutions for your Rapid Tooling needs. Our experienced team is here to support you in the design and manufacturing of Rapid Tooling components, regardless of their size or quantity. We understand the urgency and requirements of the industry for high-quality prototypes and provide you with precisely manufactured components that meet your specifications. Thanks to our additive manufacturing technologies, we can reproduce complex geometries and fine details, helping you quickly obtain high-quality prototype initial samples. Our express service ensures rapid turnaround times to optimize your time-to-market and efficiently advance your projects.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

We take the right turn! In the area of turning technology we can offer you a spectrum of prototypes, zero series and small series as well as the production of large series as a powerful partner. We process all materials, e.g. Such as automatics, tempering, stainless steels, aluminum, brass, copper and more! Max. Diameter when working rod and / or coil: Ø 65 mm Max. Diameter when machining sections: Ø 380 mm Max. Working length: 500 mm All common heat- and surface- treatments possible Assembling and more…

Request for a quote

VOXELJET AG

Germany

The VX200 is the most compact 3D printer in the voxeljet portfolio. It weighs a mere 450 kilograms and, thanks to its dimensions of only 1,700 x 900 x 1,500 mm (LxWxH), the VX200 can be installed without problems in places where space is tight, such as research laboratories. The machine is very fast, easy to operate and permits the economical production of small prototypes and design pieces. Plastic and sand can be used as the particulate materials. The build space measures 300 x 200 x 150 mm. The VX200's print head system can achieve a resolution of up to 300 dpi. The thickness of a layer applied in one cycle is 150 µm for plastic and 300 µm for sand.

Request for a quote

VOXELJET AG

Germany

The VX500 is a 3D printer for industrial applications that has been tried and tested many times over in practice. These machines can be found wherever there is a demand for the straightforward production of prototypes and models. Despite their compact dimensions, they captivate with the features of a high-performance printer, such as multi-jet print heads, integrated material handling and job boxes. The machine is very fast, easy to operate and permits cost-effective production of both individual parts and small series alike. Plastic can be used as the particulate material. The machine's build space measures 500 x 400 x 300 mm. The VX500's print head system can achieve a resolution of up to 600 dpi. The thickness of a layer applied in one cycle is 150 µm. In addition, the VX500 concept is resource-friendly: In plastic processes, the unprinted particulate material is recyclable.

Request for a quote

VOXELJET AG

Germany

Our international bestseller: the VX1000 is a universal 3D printer for industrial applications. The machine is fast, easy to operate and enables you to cost-effectively produce medium-sized molds, cores and models for making prototypes. The VX1000 is also suitable for producing small series. Plastic and sand can be used as the particulate material. The piezo print head system of the VX1000 achieves a resolution of up to 600 dpi. The machine's build space measures 1,000 x 600 x 500 mm. The thickness of a layer applied in one cycle is 150 µm for plastic and 300 µm for sand. In addition, the VX1000 concept is environmentally friendly: In plastic processes, the unprinted particulate material is recyclable.

Request for a quote

VOXELJET AG

Germany

The VX2000 is a 3D printer for industrial applications. It is a particularly good choice for cost-effectively producing large-format models from sand cores for prototyping. The VX2000 can also be used to economically manufacture small-series components. The machine is fast and easy to operate. The build space measures up to 2,000 x 1,000 x 1,000 mm. The VX2000's print head system can achieve a resolution of up to 300 dpi. A layer applied in one cycle is 300 µm thick.

Request for a quote

VOXELJET AG

Germany

The VX4000 is the world's biggest industrial 3D printing system for sand molds. It has a cohesive build space measuring 4,000 x 2,000 x 1,000 mm (LxWxH). This machine can be used to economically produce very large individual molds, a great many small series components or a combination of the two. With its uniquely large volume, the VX4000 maximizes productivity and flexibility. The unique and patented layering process was specially adapted for this printer. Instead of lowering the building platform during the printing process, the print head and coater are raised with each layer. As a result, the machine can bear the enormous weight of the building platform, which can be quickly exchanged via a rail—making it possible to print nearly continuously. Sand can be used as the particulate material. The VX4000's print head system can achieve a resolution of up to 300 dpi. A layer applied in one cycle is 300 µm thick.

Request for a quote

VOXELJET AG

Germany

• Mold measurements up to 4 x 2 x 1 m • Does away with elaborate and expensive mold set-ups • Short throughput time (a few days) • Sand molds correspond 1:1 with CAD model • Structures can be designed in accordance with requirements, without having to watch for draft angles or undercuts • Special sands prevent casting problems • Surface quality can be adjusted through use of different sands • Coarse-grained sands for high gas permeability • Considerable flexibility with changes in geometry, without additional expenses • No storage or maintenance of patterns • Cost savings particularly for complex molds and batch sizes of 1 to several hundred pieces

Request for a quote

VOXELJET AG

Germany

• Mold measurements up to 4 x 2 x 1 m • Does away with elaborate and expensive mold set-ups • Short throughput time (a few days) • Sand molds correspond 1:1 with CAD model • Structures can be designed in accordance with requirements, without having to watch for draft angles or undercuts • Special sands prevent casting problems • Surface quality can be adjusted through use of different sands • Coarse-grained sands for high gas permeability • Considerable flexibility with changes in geometry, without additional expenses • No storage or maintenance of patterns • Cost savings particularly for complex molds and batch sizes of 1 to several hundred pieces

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VOXELJET AG

Germany

• Mold measurements up to 4 x 2 x 1 m • Does away with elaborate and expensive mold set-ups • Short throughput time (a few days) • Sand molds correspond 1:1 with CAD model • Structures can be designed in accordance with requirements, without having to watch for draft angles or undercuts • Special sands prevent casting problems • Surface quality can be adjusted through use of different sands • Coarse-grained sands for high gas permeability • Considerable flexibility with changes in geometry, without additional expenses • No storage or maintenance of patterns • Cost savings particularly for complex molds and batch sizes of 1 to several hundred pieces

Request for a quote

VOXELJET AG

Germany

• Mold measurements up to 4 x 2 x 1 m • Does away with elaborate and expensive mold set-ups • Short throughput time (a few days) • Sand molds correspond 1:1 with CAD model • Structures can be designed in accordance with requirements, without having to watch for draft angles or undercuts • Special sands prevent casting problems • Surface quality can be adjusted through use of different sands • Coarse-grained sands for high gas permeability • Considerable flexibility with changes in geometry, without additional expenses • No storage or maintenance of patterns • Cost savings particularly for complex molds and batch sizes of 1 to several hundred pieces

Request for a quote

VOXELJET AG

Germany

• Model measurements up to 1.000 x 600 x 500 mm • Same handling as for conventional wax parts • Tool-less and hence more cost-effective process • Single items and small series can be produced within a few days • High degree of accuracy: ±0.4% (min. +/- 100 µm) • Wax infiltration creates closed smooth surface • Suitable for autoclaves, even for thin-walled shells • Can be burnt out in normal kiln with low emission formation • Does not expand during burn-out process, hence no shell cracking (whether gypsum or ceramics) • Residual ash contents <0.02% for polypor binder type C • All alloys can be used with lost-wax casting process

Request for a quote

VOXELJET AG

Germany

• Model measurements up to 1.000 x 600 x 500 mm • Same handling as for conventional wax parts • Tool-less and hence more cost-effective process • Single items and small series can be produced within a few days • High degree of accuracy: ±0.4% (min. +/- 100 µm) • Wax infiltration creates closed smooth surface • Suitable for autoclaves, even for thin-walled shells • Can be burnt out in normal kiln with low emission formation • Does not expand during burn-out process, hence no shell cracking (whether gypsum or ceramics) • Residual ash contents <0.02% for polypor binder type C • All alloys can be used with lost-wax casting process

Request for a quote

VOXELJET AG

Germany

• Model measurements up to 1.000 x 600 x 500 mm • Same handling as for conventional wax parts • Tool-less and hence more cost-effective process • Single items and small series can be produced within a few days • High degree of accuracy: ±0.4% (min. +/- 100 µm) • Wax infiltration creates closed smooth surface • Suitable for autoclaves, even for thin-walled shells • Can be burnt out in normal kiln with low emission formation • Does not expand during burn-out process, hence no shell cracking (whether gypsum or ceramics) • Residual ash contents <0.02% for polypor binder type C • All alloys can be used with lost-wax casting process

Request for a quote

VOXELJET AG

Germany

• Model measurements up to 1.000 x 600 x 500 mm • Same handling as for conventional wax parts • Tool-less and hence more cost-effective process • Single items and small series can be produced within a few days • High degree of accuracy: ±0.4% (min. +/- 100 µm) • Wax infiltration creates closed smooth surface • Suitable for autoclaves, even for thin-walled shells • Can be burnt out in normal kiln with low emission formation • Does not expand during burn-out process, hence no shell cracking (whether gypsum or ceramics) • Residual ash contents <0.02% for polypor binder type C • All alloys can be used with lost-wax casting process

Request for a quote

VOXELJET AG

Germany

• Model measurements up to 1.000 x 600 x 500 mm • Same handling as for conventional wax parts • Tool-less and hence more cost-effective process • Single items and small series can be produced within a few days • High degree of accuracy: ±0.4% (min. +/- 100 µm) • Wax infiltration creates closed smooth surface • Suitable for autoclaves, even for thin-walled shells • Can be burnt out in normal kiln with low emission formation • Does not expand during burn-out process, hence no shell cracking (whether gypsum or ceramics) • Residual ash contents <0.02% for polypor binder type C • All alloys can be used with lost-wax casting process

Request for a quote

VOXELJET AG

Germany

• Model measurements up to 1.000 x 600 x 500 mm • Same handling as for conventional wax parts • Tool-less and hence more cost-effective process • Single items and small series can be produced within a few days • High degree of accuracy: ±0.4% (min. +/- 100 µm) • Wax infiltration creates closed smooth surface • Suitable for autoclaves, even for thin-walled shells • Can be burnt out in normal kiln with low emission formation • Does not expand during burn-out process, hence no shell cracking (whether gypsum or ceramics) • Residual ash contents <0.02% for polypor binder type C • All alloys can be used with lost-wax casting process

Request for a quote

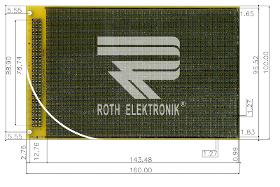

ROTH ELEKTRONIK GMBH

Germany

Epoxy fibre-glass FR4 1.50 mm Double-sided 35 µm Cu Plated through holes (PTH) Hot air leveling (HAL-leadfree) SMD hole spacing 1.27 x 1.27 mm 113 x 76 soldering pads 1.00 x 1.00 mm (8588 soldering pads) Hole diameter 0.35 mm Connector 32/64/96-channel DIN 41612 type C Size 100 x 160 mm

Request for a quote

ROTH ELEKTRONIK GMBH

Germany

Epoxy fibre-glass FR4 1.50 mm Double-sided 35 µm Cu Plated through holes (PTH) Surface chem. Sn SMD hole spacing 1.27 x 1.27 mm 108 x 69 soldering pads 1.00 x 1.00 mm (7452 soldering pads) 4 potential strips Connector 32/64/96-channel DIN 41612 type C Size 100 x 160 mm

Request for a quote

ROTH ELEKTRONIK GMBH

Germany

Epoxy fibre-glass FR4 0.80 mm Double-sided 35 µm Cu Plated through holes (PTH) Surface chem. Sn SMD hole spacing 1.27 x 1.27 mm 40 x 60 soldering pads 1.00 x 1.00 mm Hole diameter 0.35 mm 2 grids 2.54 x 2.54 mm (1/20") 17 x 32 and 18 x 32 soldering pads 2.00 x 2.00 mm Hole diameter 1.00 mm Connector 32/64/96-channel DIN 41612 type C Size 100 x 160 mm

Request for a quote

ROTH ELEKTRONIK GMBH

Germany

Epoxy fibre-glass FR4 0.80 mm Double-sided 35 µm Cu Plated through holes (PTH) Surface chem. Sn SMD hole spacing 1.27 x 1.27 mm 39 x 59 soldering pads 1.00 x 1.00 mm Hole diameter 0.35 mm Size 53 x 95 mm

Request for a quoteResults for

Prototyping - Import exportNumber of results

75 ProductsCountries

Company type

Category

- Prototypes, industrial (19)

- 3D printers (17)

- Models for the building industry (3)

- Vehicles - mechanical components and parts (2)

- Machine tools, metal machining - parts and accessories (1)

- 3D software (1)

- Optical measuring equipment (1)

- Turning - steels and metals (1)

- 3D scanner (1)

- Additives for plastics industry (1)

- Bending - steels and metals (1)

- Bending machine tools (1)

- Car tuning equipment (1)

- Electronic data processing - microcomputers (1)

- Engineering - industrial contractors (1)

- Hosting of online services (1)

- Laser - cutting and welding machines (1)

- Light-emitting diode LED (1)

- Motor racing - equipment and accessories (1)

- Potting equipment (1)