- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- production tools

Results for

Production tools - Import export

EWS WEIGELE GMBH & CO. KG

Germany

The rapid change system EWS-Varia allows to set-up a modern CNC lathe or a turning milling center – and this flexibly. A tool change will just take 20 seconds, which is an unbeatable argument especially in small batch productions whenever it is about reducing the set-up time and thus increasing the productivity. The advantages, however, are also evident in large batch productions. Preset twin tools lie at the machine, thus significantly reducing the down-times. A further advantage is provided by the variety of adaptations; so the optimal tool clamping can be selected for each operation. The inserts available include: Collet chuck holders Weldon/Whistle Notch Milling arbors Morse tapers Hydro extension Shrink adaptations The most important advantage is certainly created by the easy handling. The inserts can be changed with just one hand without counter pressure by the spindle.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Static tools form one of the EWS core areas. There is no other manufacturer in the world offering such a variety of products: More than 20,000 different tool holders are available for machine operators. Our portfolio includes VDI tool holders with shaft diameters of 16-80 as well as block tool holders of BMT55-BMT85 to machine-specific holders for MAZAK, Okuma or Mori Seiki, to name just a few. We also offer prism holders according to DIN 69881 (VDI3425 Bl.3) in all nominal sizes. Our standard portfolio includes Capto, HSK, KM and ABS adaptations in addition to the standard holders. Moreover, our scope of supply includes special holding fixtures made according to customer drawings or innovative solutions of the EWS engineers designed to master production engineering challenges. The tool holders are manufactured at our factory in Uhingen and rightly carry the label: Made in Germany! Boring bar holder BMT Capto C4 Double boring bar holder Capto Bar Gripper Infee

Request for a quote

PRESSTA EISELE GMBH

Germany

Punch tools to work aluminium profiles Customized Production Single or Chain tools Holes, notches, bending Tool size up to 1.200 mm Power up to 800 KN

Request for a quote

MESUTRONIC GMBH

Germany

METAL SEPARATOR FOR THE PHARMACEUTICAL INDUSTRY FOR THE INSPECTION OF TABLETS AND CAPSULES. Detects and separates all metals encapsulated or as loose parts. Meets the highest h ygiene requirements. Fast decontamination of all product touching parts without tools. Fits every tablet press and deduster installation. High throughput owing to round equipment design DN50.

Request for a quote

BIZERBA SE & CO. KG

Germany

With the master data maintenance tool _dataMaintenance.BRAIN you can centrally create and maintain PLU data including label parameters and send them to Bizerba devices. Only verified data is loaded for production. The master data maintenance tool _dataMaintenance.BRAIN is closely integrated with Bizerba devices and applications. The user-friendly interface optimally shows the data structure of each Bizerba weigh price labeler and checkweigher. Compatibility with Windows® 8.1 ensures future support. Depending on the size of your company we have the right software version (Basic, Standard or Professional) for you.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Control room application mPilot is a control room application for Mahlo equipment. The software allows the user to configure up to ten Mahlo devices with one control centre. Individually selected data of several devices are clearly arranged. The innovative control tool supports production and shift managers in handling their daily business as efficiently as possible. Key elements Display of running processes of up to ten Mahlo machines Job control (configure jobs and recipes) Configuration of product lines and machines Alarm management (current and historical warnings) Various communication protocols (OPC UA, OPC DA, Modbus TCP, Profibus, Profinet, Ethernet/IP) Start of predefined jobs (only with mCockpit)

Request for a quote

MICRO-EPSILON

Germany

The RTP 8302.T is based on the laser triangulation sensors and therefore ensures the measurement being independently from material constants. In order to ensure highest precision, the laser beams of the sensors are accurately adjusted during the production process using optoelectronic tools which have been specially developed. The system is ideal for monitoring high-dynamically processes due to its high measuring rate. The C-frame mechanics of the system disposes of an automated in-situ calibration in order to avoid interferences caused by temperature.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

CIC will be happy to support you in planning, securing, controlling, monitoring and optimizing your quality management, e.g. with: advanced quality planning supplier quality purchased part quality component qualification product engineering Supplier Audit Internal audits Process monitoring and process optimization Production control and monitoring at the supplier bottleneck coordination production readiness tool design Tool tracking mold trials Gauge concepts and gauge acceptance component measurements Resident Engineering Task Force Abbreviations such as APQP, PEP, FMEA, PPAP, 8-D, 5Why are not foreign words for us but common tools.

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

Where it says carbon on the package, there is innovation inside! That's because carbon brushes from MACK are playing their part in helping gantry cranes and container-handling technology go green. Lower diesel fuel consumption, less air pollution, significant increase in productivity: Slowly but surely, new technology is bringing the electrification of container-stacking cranes to port terminals around the world. ERTG (Electrified Rubber-Tyred Gantry) is the keyword. And: MACK is at the forefront when contact shoes are required, at times even for conductor lines that are several hundred metres long. We would be pleased to play a major role in your ‘green harbour’ projects with our high-quality, durable carbon brushes and holders, making our contribution towards a future that is more environmentally friendly in the process. Our tool production and our injection moulding workshop work for you exactly to your needs.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

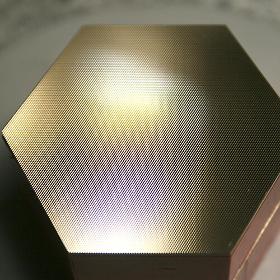

With the chip-removing microstructuring of metal surfaces, LT Ultra offers the right manufacturing technology for the production of embossing tools with optical surface qualities that allow economical replication in large numbers. Examples of microstructuring are the production of microfluidics or microlenses on our ultra-precise multi-axis machines. We can manufacture the structures directly in various materials such as brass, chemically deposited nickel or in selected hardened steels.For the replicating production of optical components, ultra-precise mold inserts made of steel are of particular interest due to their very long service life compared to other materials. In order to avoid the final polishing, which often leads to an undesirable change in shape or which is impossible due to a high structure density, LT Ultra offers ultrasound-assisted machining of steels with geometrically defined cutting edges made of monocrystalline diamond.

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Profiline – This EZM brand name stands for cold-drawn standard sec-tions and special sections to customer drawings in virtually all steel materials. Optimum heat-treatment, pickling and coating facilities are available for every material group. As a result of the continuous improvement of our in-house tool production operations, EZM can manufacture sections whose geometry and shape are as near as possible to the net shape, maintaining the tightest tolerances and producing flawless surfaces. Our cold-drawn sections are successfully used when metal cutting is uneconomical due to the great effort and material losses involved, or when the section is to be given specific properties that can only be achieved by targeted cold-forming. In our plant EZM Profil Bearbeitung, based in Rohr/Thüringen, sections are manufactured by machining up to 6,200 mm length and a maximum crossing-section of 125 mm, which are needed for for example for linear guides in the machine and plant...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Profiline – This EZM brand name stands for cold-drawn standard sec-tions and special sections to customer drawings in virtually all steel materials. Optimum heat-treatment, pickling and coating facilities are available for every material group. As a result of the continuous improvement of our in-house tool production operations, EZM can manufacture sections whose geometry and shape are as near as possible to the net shape, maintaining the tightest tolerances and producing flawless surfaces. Our cold-drawn sections are successfully used when metal cutting is uneconomical due to the great effort and material losses involved, or when the section is to be given specific properties that can only be achieved by targeted cold-forming. In our plant EZM Profil Bearbeitung, based in Rohr/Thüringen, sections are manufactured by machining up to 6,200 mm length and a maximum crossing-section of 125 mm, which are needed for for example for linear guides in the machine and plant...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Profiline – This EZM brand name stands for cold-drawn standard sec-tions and special sections to customer drawings in virtually all steel materials. Optimum heat-treatment, pickling and coating facilities are available for every material group. As a result of the continuous improvement of our in-house tool production operations, EZM can manufacture sections whose geometry and shape are as near as possible to the net shape, maintaining the tightest tolerances and producing flawless surfaces. Our cold-drawn sections are successfully used when metal cutting is uneconomical due to the great effort and material losses involved, or when the section is to be given specific properties that can only be achieved by targeted cold-forming. In our plant EZM Profil Bearbeitung, based in Rohr/Thüringen, sections are manufactured by machining up to 6,200 mm length and a maximum crossing-section of 125 mm, which are needed for for example for linear guides in the machine and plant...

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Corrosion protection of metal semi-finished products and spare parts during transportation and storage Temporary storage of forms, machines and tools in production and maintenance Advantages and benefits Environmentally friendly VOC-free product on a water base Workplace-friendly and not detrimental to health, since emissions (vapours) from volatile organic compounds do not arise during application Setting of the layer thickness for optimal corrosion protection through dilution with water possible In case of mass coating, pre-heating of the parts to accelerate drying possible Dry wax film fast to handling Can be removed easily with warm water and water-based cleaners, such as OKS 2650 Good adhesion on metal surfaces Neutral with respect to most plastics and paints

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Profiline – This EZM brand name stands for cold-drawn standard sec-tions and special sections to customer drawings in virtually all steel materials. Optimum heat-treatment, pickling and coating facilities are available for every material group. As a result of the continuous improvement of our in-house tool production operations, EZM can manufacture sections whose geometry and shape are as near as possible to the net shape, maintaining the tightest tolerances and producing flawless surfaces. Our cold-drawn sections are successfully used when metal cutting is uneconomical due to the great effort and material losses involved, or when the section is to be given specific properties that can only be achieved by targeted cold-forming. In our plant EZM Profil Bearbeitung, based in Rohr/Thüringen, sections are manufactured by machining up to 6,200 mm length and a maximum crossing-section of 125 mm, which are needed for for example for linear guides in the machine and plant...

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

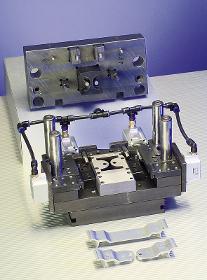

In order to get started with low pressure molding technology, for prototyping new projects and producing small series, Labline offers a selection of small devices tailored to the requirements of low pressure molding technology. The basis here is the hand-held casting gun with a 0.2l tank for filling the casting materials in granulate form. In order to achieve process stability and reproducibility even with this manual processing, a timer can be connected. Two different clamping devices are available for convenient handling of sample and pre-series tools. product [hot melt application systems, hot melt coating machines for paper, hot melt, hot melt adhesive, hot melt adhesives, special machines for adhesive processing, hot melt packaging, machine for gluing, machines for gluing, hot melts, gluing machines, hot melt coating, gluing machines for labels, laboratory coating machines, systems for adhesive technology]

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Hotmelt Extruder OptiMel has developed an extruder system that is specially adapted to the conditions and parameters in electronics encapsulation. A special design uses the advantages of the extruder when melting the materials and implements the injection via an additional piston unit. This process avoids pressure peaks and combines the advantages of extruders with the requirements when processing sensitive electronic components. product [extrusion tools, extrusion tools, hotmelt application systems, extrusion tool, extrusion tool, plastic welding extruder, hotmelt adhesive, extruder systems, extruder system, extrusion machines, hotmelt, hotmelt adhesives, extruder construction, extruder pumps, extrusion machine]

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ASP GERMANY

Germany

The very different requirements created by diverse welding techniques mean that specific products have to be specially developed. The industrial fabrics we use have specific coatings that leave the cover flexible but resistant to spatter and weld splashes. Their para-aramid base has excellent mechanical strength. Production tooling protection is a necessity. ASP offers a wide range of protective covers for all types of welding guns, regardless of the welding technology involved (pneumatic, hydraulic or electric motor).

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

USM 10 The skiving machine for the workshop. For skiving hoses up to 2” on the inside and the outside. 0.37 kW drive. USM 10 ecoline variant in 1-phase design, all others in 3-phase design. USM 10 S The new skiving machine: The lowest change-over times due to preset tool. Higher productivity due to low change-over times and user friendly operation for optimum results.

Request for a quote

KROMER GMBH - HERSTELLER UND LIEFERANT FÜR FEDERZÜGE UND BALANCER

Germany

- zero-gravity ability - tool handling - tool positioning - ergonomic work place - assembly / production - tool support - quality made in germany

Request for a quote

KROMER GMBH - HERSTELLER UND LIEFERANT FÜR FEDERZÜGE UND BALANCER

Germany

- zero-gravity ability - ergonomic tool support for industrial environements - assembly & production - handling of tools - positioning of tools

Request for a quote

KROMER GMBH - HERSTELLER UND LIEFERANT FÜR FEDERZÜGE UND BALANCER

Germany

- zero-gravity ability - ergonomic tool support for industrial environements - assembly & production - handling of tools - positioning of tools

Request for a quote

KROMER GMBH - HERSTELLER UND LIEFERANT FÜR FEDERZÜGE UND BALANCER

Germany

- zero-gravity ability - ergonomic tool support for industrial environements - assembly & production - handling of tools - positioning of tools

Request for a quote

KROMER GMBH - HERSTELLER UND LIEFERANT FÜR FEDERZÜGE UND BALANCER

Germany

- zero-gravity ability - ergonomic tool support for industrial environements - assembly & production - handling of tools - positioning of tools

Request for a quote

KROMER GMBH - HERSTELLER UND LIEFERANT FÜR FEDERZÜGE UND BALANCER

Germany

- zero-gravity ability - tool positioning and handling - ergonomic tool support - assembly / production - made in germany

Request for a quote

KROMER GMBH - HERSTELLER UND LIEFERANT FÜR FEDERZÜGE UND BALANCER

Germany

Balancers are holding tools in a waiting position. The needed tools in production are always ready for use. They increase safety and ergonomics at workplace. Features: Safe suspension with freely rotating and swivelling screw-type spring hook Housing of very impact-resistant and abrasion-resistant plastic Housing cover of painted sheet steel Cable drum of high-strength, abrasion-resistant plastic High-strength special suspension spring High-strength steel cable Infinitely adjustable cable stop buffer Cable wedge allows infinite adjustment of cable length Screw-type spring hook for load suspension Simplified load setting

Request for a quote

STARRAG GMBH

Germany

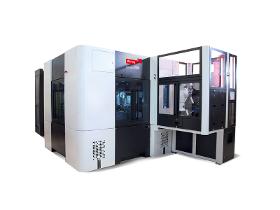

A standalone monostation machine A compact industrial concept for maximum performance taking up minimum floor space With its dual spindle concept enabling concurrent tool change operations, its high dynamic acceleration, its powered spindles capable of a rotation speed of up to 60.000 min1, its high number of tools, the s100 is a modern production tool pushing back the boundaries of highprecision machining. The s100 range makes it possible to produce highly complex parts. Ideal for 3 axis machining of watch movement parts, it has also proven itself unbeatable in a whole host of fields, such as mobile telephony, electronics or nanotechnologies. Features Unique dual spindle concept Highly dynamic acceleration, up to 3g

Request for a quote

STARRAG GMBH

Germany

A 4station transfer machine A compact industrial concept for maximum performance taking up minimum floor space With its dual spindle concept enabling concurrent tool change operations, its high dynamic acceleration, its powered spindles capable of a rotation speed of up to 60.000 min1, its high number of tools, the s100 is a modern production tool pushing back the boundaries of highprecision machining. The s100 range makes it possible to produce highly complex parts. Ideal for 3 axis machining of watch movement parts, it has also proven itself unbeatable in a whole host of fields, such as mobile telephony, electronics or nanotechnologies. Features Unique dual spindle concept Highly dynamic acceleration, up to 3g 4 machining stations Up to 36 tools integrated into the machine

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

SpeedCore is a newly developed substrate for hobs. The increased hot hardness of the intermetallic cutting material allows for cutting speeds of at least 30 % higher compared with HSSPM4/ 14 hobs, resulting in shorter production times without sacrificing tool live and ocmplies with the demand of customers for easy handling and easier recycling. Combining the new SpeedCore substrate with a custom coating achieves top performance with easy implementation and high reliability. Advantages - Improved productivity of up to 70 % - Process reliability (like HSS-PM) - Easy to implement; also on older or unstable machines - Regrinding and coating possible without problems

Request for a quoteResults for

Production tools - Import exportNumber of results

41 ProductsCountries

Company type

Category

- Lifting equipment (6)

- Milling - machine tools (2)

- Packing and packaging - machinery and equipment (2)

- Machine tools, metal machining - parts and accessories (2)

- Measurement - Equipment & Instruments (2)

- Potting equipment (2)

- Software (2)

- Tools & Hardware (2)

- Steels and metals - machining (1)

- Embossing machine tools (1)

- Handling - Machines & Equipment (1)

- Hydraulic equipment (1)

- Industrial tools (1)

- Models for the building industry (1)

- Numerical control systems - minicomputers and mainframes (1)

- Plastics - machines and material for industry (1)

- Portable power sanders (1)

- Sensors (1)

- Silicones (1)

- Vehicles - mechanical components and parts (1)