- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- process filters

Results for

Process filters - Import export

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

CF 30 G equipment is supplied completely assembled and ready for operation. The dust collection unit is suited for intermittent operation only, because regular cleaning of the pocket filter element in certain intervals is an absolutely must for the proper operation of the equipment. The cleaning intervals will depend on the operating conditions and must be established by experience. Normally cleaning intervals will be between operating times of 30 minutes to two hours. It is a prerequisite for sufficient and intensive cleaning of the filter cloth that dust collecting is interrupted during cleaning to achieve static pressures on the filter material. A retention time of 1 - 2,5 minutes between the end of the suction and the beginning of the cleaning process is therefore required. The filtered air must be removed outside - do not lead back to closed rooms!

Request for a quoteFAUDI GMBH

Germany

Advantages Parallel alignment of multiple Sieve Cylinders enables a large filtration area on limited space Higher filtration degree possible through bag inserts Area of application Applicable as pipeline and process filter Flow rate Various filter sizes and the modular design enable any required flow rate. classification number S26 Filter aid - Filtration degree 0,5 µm - 20 mm Medium low viscosity liquids, gases Filter material perforated plate cylinder, mesh, bags

Request for a quote

APROVIS

Germany

* FriCon - gas dehumidification * Gas heaters * ActiCo - activated carbon filters * Gas compressors * Process gas heat exchangers

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

Our wide selection of different types of filter cartridges offers you the greatest possible flexibility. FTJ filter cartridges have maximum dirt holding capacity and are suitable for large volume flows as well as complex filtration processes. Absolute rated filter cartridges Type: AT Genius / CLA Genius-FTJ

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

Our wide selection of different types of filter cartridges offers you the greatest possible flexibility. FTJ filter cartridges have maximum dirt holding capacity and are suitable for large volume flows as well as complex filtration processes. Absolute rated filter cartridges Type: AT

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

By using an array of sophisticated sound sensors, the SV600 can be mounted close to any equipment or asset, to any area of the production line, or where human access is restricted or dangerous to ensure you can monitor the most important parts of your facility without interruption. As a fixed, automated solution, the SV600 integrates with your process and eliminates the need for lengthy fault-finding processes such as soapy water tests, when used as part of your product leak testing process. By continuously monitoring your environment, you can quickly detect and fix air leaks – reducing your consumption of compressed air and energy to help save your facility money. Key Features: High-end 24/7 acoustic monitoring 64-Digital MEMS microphones placed in a Sunflower Array Integrated visual light camera Powerful processor for onboard real time processing Sound classification Frequency filtering dB values and sound intensity mapping Event triggering

Request for a quoteFAUDI GMBH

Germany

Advantages Compact design Low assembly requirements Very economic due to compact and standardized design Area of application For high demands on the filtrate quality in grinding processes. Flow rate Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid without Filtration degree 30-100 µm Medium oil Filter material filter cartridges

Request for a quoteFAUDI GMBH

Germany

Advantages Filter aid-free filtration Compact design Applicable for various machining processes Area of application For high demands on the filtrate quality in grinding processes. Flow rate Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid without Filtration degree 5-10 µm Medium oil Filter material filter cartridges

Request for a quote

FORBO SIEGLING GMBH

Germany

Different mesh sizes with open areas of 60% max. make Forbo mesh belts ideal processing belts for cleaning, drying, filtering and cooling. The belts can be supplied in different versions, for example with reinforced belt edges, with fibre-glass or Kevlar-fabric, with tracking- and lateral-profiles.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Filter out contaminants during the dissolution testing process POREX ® Dissolution Filters are used in conjunction with pharmaceutical tablet and capsule products to help filter contaminates during the dissolution testing process. Heavy metal free POREX ® Dissolution Filters are available in cannula, circular/disk and filter frit designs in a wide variety of porosities and: Meet U.S. Pharmacopeia Standards for elemental impurities Can be used with molecular diagnostics, clinical IVD, infectious diseases and research applications. Will withstand automated assembly equipment and resist breakage due to strong, durable and lightweight construction. Are designed with chemically-resistant media which will tolerate most acids and bases. Offer instant pore size identification with color-coded resins. Cannula Filters POREX ® Cannula Filters are used on the end of a sampling cannula and feature a large surface area and optimized flow rate for an ideal choice in applications with a high...

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

We adapt our filter bags exactly to your specific requirements and thus create the highest process reliability for you. FTJ filter bags are available in sewn and welded design, with plastic collar and stainless steel ring. We offer standard filter bags, high performance filter bags and absolute rated filter bags. Standard filter bags made of needle felt in PP or PES Optionally with plastic collar or stainless steel ring or galvanized ring

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

We adapt our filter bags exactly to your specific requirements and thus create the highest process reliability for you. FTJ filter bags are available in sewn and welded design, with plastic collar and stainless steel ring. We offer standard filter bags, high performance filter bags and absolute rated filter bags. Microfiber multi-layer filter bags with up to 3 m² filter area Very high solids absorption capacity (up to approx. 2 kg) Extremely long service life Graded depth filtration (with integrated pre-filters) Absolute rated separation of 98 - 99.99% Guaranteed without fibre migration Fully welded seams

Request for a quote

CANDELA BIO-HANDELS GMBH

Germany

The oil is extracted from the pulp of the fruit, through an expeller pressing process, to obtain a filtered, crude oil (unrefined) and without additives. Rich in Omega 9, it helps maintain the hair's natural color and shine, strengthening the hair follicles. It can be use in formulas for the treatment of dandruff and to revitalize hair, increasing its resistance and recovery. Apply to the scalp and massage for five minutes, spreading it along the hair.

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

We adapt our filter bags exactly to your specific requirements and thus create the highest process reliability for you. FTJ filter bags are available in sewn and welded design, with plastic collar and stainless steel ring. We offer standard filter bags, high performance filter bags and absolute rated filter bags. High performance filter bag made of needle felt in PP or PES (welded/sewn version) Longer lifetime Higher dirt absorption capacity Fully welded seams Special bag filter seal Full compatibility with the entire FTJ filter housing program Production according to the highest quality standards

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

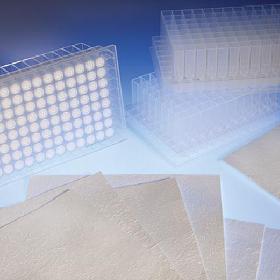

Recover filtrates and particulate retentates thoroughly and quickly Used for high recovery of filtrates and particulate retentates, POREX® deep well filter media are designed for high-throughput sample processing. Our POREX deep well filter plate media features: High sample recovery for many processing techniques including filtration, vacuum filtration, centrifugation or other positive pressure techniques Minimal contamination–Porous material structure prevents cross talk between adjacent well walls. Proprietary surface modification – Materials allow multiple functionalities or sorbent addition, including CPG, carbon C18 or C8, and media is suitable for vacuum filtration, centrifugation or other positive pressure techniques. Tested by independent laboratories - Certified pure materials ensure performance, accuracy and reproducibility. Features Certified Pure Porex™ Materials Filter Media Purity – no material additives or contaminants No Heavy Metal Interference No other...

Request for a quote

FILTERTECHNIK JÄGER GMBH

Germany

We adapt our filter bags exactly to your specific requirements and thus create the highest process reliability for you. FTJ filter bags are available in sewn and welded design, with plastic collar and stainless steel ring. We offer standard filter bags, high performance filter bags and absolute rated filter bags. Made of monofilament fabric (surface filtration) Optionally with plastic collar or stainless steel ring

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Enhance semiconductor processing with pure materials Our high-purity diffusion tubes allow semiconductor processing facilities a precise way to diffuse, filter and distribute process gases. Specifically designed to precise flow and dimensional tolerances, POREX® diffusion tubes: Ensure purity –Material is backed by the Certified Pure POREX™ program of independent laboratory testing of leachables, extractables and interfering substances. Deliver precise flow rates and tolerances–Engineered for tight pore size and volume control. Improve process effectiveness–Design is customizable per application requirements. request sample ask an engineer

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

F.E.S. GMBH

Germany

Multifunctional filters are used for fine filtration of low-viscosity oils with low levels of contamination. The filter systems can be operated as either precoat filters or edge filters, and conversion between the two modes is easily achievable. This versatile design allows the filter systems to be well-adapted to various filtration tasks. The achievable filtration fineness ranges from 1 to 5 µm. When operating as an edge filter, the filter regeneration process is fully automatic, while the precoat filter version requires manual cleaning. Multifunctional filter systems can be operated as either edge filters or precoat filters: ultifunctional Filter MFF300-AF2.5 to MFF800-SF120 Multifunctional filters are used for fine filtration of low-viscosity oils with low levels of contamination. The filter systems can be operated as either precoat filters or edge filters, and conversion between the two modes is easily achievable.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Up to three processes – cleaning, painting and drying in one booth. Multi-process booth Just one booth for cleaning, painting and drying (up to three processes). Dry paint filter and wet cleaning in one booth – that is actually a contradiction in itself. Thanks to the separate air guidance, the exhaust air is fed downwards through the grating when drying and laterally through the filter boxes when painting, so that very little moisture enters the dry filter and virtually no particles get into the cleaning water. In order to prevent the ingress of particles, the gratings can additionally be covered over during painting. Any paint that does get into the cleaning water is usually already dry, so that no dilution in the classic sense takes place; instead, it behaves like small, filterable plastic balls. Advantages:

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

Premium infrared emitter with a high performance nanoamorphous carbon membrane. This achieves membrane temperatures of up to 850 °C for high and long-term stable radiation output. The JSIR 350 IR emitter in the HermeSEAL® option is a high performance emitter for particularly demanding gas analysis applications in medicine, industry and aerospace. The packaging version in the standard TO39 housing with reflector and window (SiARC) is suitable for measurement distances from 2 cm and optimizes the emission in the wavelength range from UV to 15 µm. Due to the HermeSEAL® technology option, this IR source can be used in harsh environments and is insensitive to high temperatures, humidity or aggressive gases. In the patented HermseSEAL® packaging process, filters are connected to the housing by soldering. This hermetically seals the inside of the housing. The sensitive membrane of the infrared source is protected from harmful ambient influences which increases its lifetime and reliability.

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

Premium infrared emitter with a high performance nanoamorphous carbon membrane. This achieves membrane temperatures of up to 850 °C for high and long-term stable radiation performance. The JSIR 350 IR emitter in the HermeSEAL® option is a high performance emitter for particularly demanding gas analysis applications in medicine, industry and aerospace. The packaging version in the standard TO39 housing with reflector and window (sapphire) is suitable for measurement distances from 2 cm and optimizes the emission in the wavelength range from 2.5 to 5.5 µm. Due to the HermeSEAL® technology, this IR emitter can be used in harsh environments and is insensitive to high temperatures, humidity or aggressive gases. In the patented HermseSEAL® packaging process, filters are connected to the housing by soldering. This hermetically seals the inside of the housing. The sensitive membrane of the IR source is protected from harmful ambient influences which increases its lifetime and reliability.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

MSE stainless steel filter presses comply with the high hygiene and purity standards both in design and processing. With the stainless steel filter press, all components in contact with the product are covered with high-quality stainless steel. This also provides optimum protection against corrosion. FDA-COMPLIANT SOLID-LIQUID SEPARATION WITH THE MSE STAINLESS STEEL FILTER PRESS A large number of materials with different properties are used in the food sector in particular. Here, especially care must be taken to ensure that no ingredients are released into the food. The law stipulates a FDA certification for this. Accordingly, all materials used must be FDA-certified. The FDA certification stands for high purity and durability. Each component such as the filter plates, filter cloths and piping systems complies with the FDA guidelines. This contributes to high hygiene and safety requirements.

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

The pyro-detector measures methanol (CH4O/half structure formula: CH3OH) & ethanol (C2H5OH) at ambient temperatures between -20 and 85 °C. With its high detectivity of up to 4.0*10^8 cm√Hz/W and a sensitivity of up to 200000 V/W, the 2-channel detector represents the high end solution for demanding applications in medical or industrial production and process applications. The optical filter with a CWL of 9663 ± 80 nm and a HBW of 240 ± 40 nm combined with the reference channel are specially designed to analyze typical alcohol compounds. The exceptional signal values result from the combination of a broad spectral sensitivity of 2 - 15 µm (optimized from 3 - 5 µm), a high sensitivity with a modulation frequency of up to 100 Hz, a low microphone effect due to the low membrane mass, very low temperature dependence and an amplified signal in current mode. The reliable measurement results are furthermore secured by a high read-out rate up to 100 Hz as well as by the short response time.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

The hot filter press combines the standard process steps of a membrane filter press, (filtration, filter cake washing and squeezing), with the additional function of a thermal filter cake drying (TCD). As a result, all process steps are carried out in one plant, the hot filter press. Dewatering and drying of the resulting filter cake is thus done without a downstream drying process. Cost-intensive and time-consuming vacuum contact drying is therefore no longer necessary. FUNCTIONAL PRINCIPLE OF THE HOT FILTER PRESS – WITH THERMAL FILTER CAKE DRYING In contrast to the conventional method, the system consists of membrane filter plates and heat exchanger plates, which are installed alternately in a filter press. For thermal drying, hot steam and/or oil is applied to the working space behind the membrane and the filter cake is thermally dried accordingly. The advantage of this process is that a high dry matter content (DM content) of over 90% is achieved.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

Based on the decisive properties of the flexible material, the rubberised filter press is mainly used for the filtration of particularly aggressive suspensions and environments. The aggressive suspensions include, for example, solvents or acids. In this context, the conventional painting of the steel parts is no longer sufficient. THE RUBBERIZED FILTER PRESS OF MSE AS PROTECTIVE MEASURES AGAINST AGGRESSIVE SUSPENSIONS In a complex process, the load-bearing filter press components are coated with a layer of 3mm thick plastic. In the case of the rubberised filter press, the hydraulic stands, feed stand, pressure plate and supporting beams are hard rubberised and the smaller components are made of polypropylene. It is also possible to rubberise only the components in contact with the product, such as the feed stand and the pressure plate. The composition of the rubber coating depends on the special surface requirements of our customers.

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

The IR Thermopile can be used to measure methanol (CH4O / half structure formula: CH3OH) & ethanol (C2H5OH) at ambient temperatures between -20 and 85 °C. With its very high detectivity of up to 6.27*10^8 cm√Hz/W and a sensitivity of up to 171 V/W, the 2-channel detector is the high end solution for demanding applications in medical technology or industrial production and process applications. The optical filter window with a CWL of 9663 ± 80 nm and a HBW of 240 ± 40 nm is specifically designed for NDIR gas analysis of these typical alcohol compounds. These signal values, which are comparable to pyrodetectors, are achieved by the interaction of chip design, integrated thermistor for reference temperature determination, an interference absorber and backgassing with krypton. The precise measurement results are further secured by the second reference channel (CWL: 5060 ± 25, HBW: 100 ± 15 nm).

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

SEPARO A solder recycler for the electronic industry The solder recycler SEPARO is designed to capture and process dross for reuse. Dross, a side effect of the solder process requires special handling that is very costly. This unit not only provides considerable savings but has the added benefit of being right in your own manufacturing environment. SEPARO is primarily used in the electronic industry but has proved, by eliminating the outsourcing, to be very useful in other parts of the tin processing industry and the consequent disposal of alloy waste SEPARO activates the specific weight of the materials that are to be separated. After a filtering process the reusable alloy settles in the lower section of the pot while the dross floats on the surface.

Request for a quote

MAYFRAN GMBH

Germany

Machine pump back stations are the ideal solution for the transport of swarf and coolant (oil or emulsion). They are easy to retrofit nearly, to all types of machine tools. Crushers must be added at those machines producing long swarf. High pressure systems can be added easily. Swarf and coolant (oil as well as emulsion) will be conveyed through pipes to a central filter or processing plant

Request for a quote

WESTFALEN CARE GMBH

Germany

"Special features: ›Innovative 1-layer filter material instead of the standard 3-layer material with a significantly lighter weight of ≤ 45 [g / m2] ›Production site: Lichtenau in North Rhine-Westphalia ›Use of 100% renewable energies (RE) in the production process Description: Innovative 1-layer filter material instead of the commercially available 3-layer material with a significantly lighter weight of ≤ 45 [g / m2], Production site: Lichtenau in North Rhine-Westphalia, Use of 100% renewable energies (RE) in the production process. Main features: Particularly suitable due to its pleasantly soft comfort in the common folding design, High quality and skin-friendly material, completely hydrophobic, does not allow liquids to pass through and enables easier breathing, Anatomically adaptable shape with nose clip and elastic ear straps (not latex-free). Instructions for use: For private use only. Not a medical device or personal protective equipment.

Request for a quoteResults for

Process filters - Import exportNumber of results

33 ProductsCountries

Company type

Category

- Filtering equipment and supplies (6)

- Drainage systems and equipment (3)

- Sensors (3)

- Acoustic equipment, electric - professional sound-engineering (1)

- Biogas and biofuel - energy use (1)

- Conveyor belts (1)

- Cosmetics (1)

- Cutting - machine tools (1)

- Dust extraction installations and equipment (1)

- Finishing of surfaces - machinery (1)

- Heat detectors (1)

- Industrial equipment hire (1)

- Lighting, street, industrial and commercial (1)

- Masks, safety (1)

- Vegetable oils (1)