- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressing materials

Results for

Pressing materials - Import export

LÖDIGE INDUSTRIES GMBH

Germany

Precision handling for heavy loads From end-of-line, through rack handling, to automated storage: Lödige has complete control of all the materials handling processes required in the press shop — including tool handling and systems for improved tool maintenance. Your advantages using Lödige solutions in the press shop: Ergonomic tool maintenance Coil handling up to 40 t Safe provision of pressed components Lifting and tilting tables up to 40 t Connection to pressed component storage Linked materials handling systems

Request for a quote

IGUS® GMBH

Germany

Save 88% assembly time with cost-effective energy chain for intralogistics and crane systems. The igus autoglide 5 system transfers energy, data, fluids, and air safely in a single system, requires almost no maintenance, and is also very cost-effective, including a 2400.07AG.075.0 e-chain, steel cable guide, harnessed bus cable, and five single cores of 6mm² each.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

Reducing transportation costs, compressing material for feeding to existing pressed-waste containers or baling presses, or shredding of material for conveyor belt feeding are good reasons for deploying a cardboard shredder. With the EKZ cardboard shredder and FKZ paperboard shredder, ERDWICH’s two rugged machines offer 100% process reliability in a range of form factors. Whether you need to shred packaging or process cardboard waste for feeding into existing conveyor systems, ERDWICH can always offer you a perfect solution tailored to your requirements.

Request for a quote

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

In the area of elastomer technology, the Zimmer Group uses the most modern production processes to manufacture sophisticated workpieces from elastomers. In addition to the transfer molding process, in which the elastomer is placed in a mold, pressed into shape with a die and vulcanized under pressure and heat, we also use the injection transfer molding process. Here, the starting materials are pressed into the mold on an injection molding machine and vulcanize out there. With these two processes, we process a wide range of elastomers such as NBR, silicone, EPDM, FPM or polyurethane. In terms of quantities as well as dimensions, the sky's the limit, because we can manufacture almost any quantity required, from special solutions in quantities of one to medium-sized small batches and large series of more than 10,000 units.

Request for a quote

CARL SCHMIDT SOHN GMBH

Germany

Wood fiber cutting board LUBECK use various natural materials and pressed under extremely high pressure and heat, so the cutting board is exceptionally strong, but still retains the texture and natural appearance of the wood. It has a high-density surface and non-absorbent properties, which effectively prevents mildew and bacteria.

Request for a quote

SPIROL

Germany

Since the development of coil springs in turret tooling, engineers have been challenged to increase the productivity of turret presses even further. In a traditional press, the option of material type and material thickness is limited by the coil springs inability to produce a high force in a short linear distance. When this performance is necessary, coil springs will have a negative effect on the quality of the formed product and efficiency of the manufacturing process. SPIROL® Disc Springs are the solution to form thick materials, large extrusions, and more complex designs. When stacked in series, they are capable of providing a greater, more consistent stripping force than coil springs and require less space. They have become an instrumental component in the advancement of turret punch press tooling. Visit www.SPIROL.com to learn more!

Request for a quote

SPIROL

Germany

SPIROL's DP100 Straight Pins have smooth outer diameters with no retention features such as knurls or barbs. When used as a press-fit pin, the DP100 Straight Pin is pressed into a hole sized slightly smaller than the diameter of the pin. SPIROL's DP100 Straight Pins are suitable for press fit in host materials that can withstand compression in the order of 0.05mm – 0.08mm (.002” – .003”). The actual recommended hole size for a press-fit depends on the actual host material. It is for this reason that SPIROL Engineering should be consulted for the recommended hole size when DP100 Straight Pins are intended to be press-fit into an assembly. Straight Pins are a great option for applications that do not require the tight tolerances of Machined Solid Pins or Ground Solid Dowels. SPIROL Series DP100 Straight Pin consists of metric diameters ranging from Ø2mm to Ø6mm and inch diameters ranging from Ø.078" (5/64) to Ø.250" (1/4).

Request for a quote

RUF MASCHINENBAU GMBH & CO. KG

Germany

The RUF briquetting systems of the Biomass series process dust, shavings and wooden chips into briquettes of consistently high quality and density. Varying bulk densities are offset automatically during the process. These materials can be pressed into a compact form without the use of binders. It is important that the moisture content of the chips is below 15%, preferably under 12%, and that the chip size does not exceed 50mm. The general rule is that the finer the material is, the smoother and more solid the surfaces and edges of the resulting briquette. The systems can be equipped with a multitude of options, thus optimally adapting them to customer needs. This series offers maximum flexibility. All systems are extremely energy efficient thanks to the innovative RUF hydraulic system. Depending on the model, the machines are equipped with motors ranging between 4 kW and 90 kW. The throughput capacities of the RUF Biomass presses range between 50 and 1,300 kg/h.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

We reserve the right to make technical changes without notice. Options are machine parts that can only be ordered while buying the machine. Press designed specifically for the production of automotive hoses. A good example for such a tailor-made solution is the HMC 1-25 and the HMC 1-30 with patented C-shaped crimping tool designed for radial insertion of complex hose lines. This special press is an ergonomically designed, low-noise machine that requires no lubrication. It has been specifically devised for the production of hoses for the automotive industry, offering outstanding press forces and precision. With PFC and other optional features, you can adjust the press force to process materials that are easily damaged, producing strong and lasting connections without any need for gluing, screwing or welding.

Request for a quote

FRIMO GROUP GMBH

Germany

Adhesive-free equipment Bonding with the substrate component is carried out without adhesive. These processes are particularly useful for back-injected or back-pressed components, where the decorative material needs to cover component edges.

Request for a quote

FRIMO GROUP GMBH

Germany

For sophisticated decorative materials Press laminating is mainly used to process materials that are unsuitable for vacuum processes, such as textiles, materials with and without foam backings or non-stretchable cover materials like leather or Alcantara. Processing these materials requires high quality tooling and machinery to ensure the quality of the grain, the soft touch and the color remain intact. The decorative element and the substrate are usually laminated together by being pressed between two hard instruments. Precise decor positioning and tool arrangements ensure optimal laminating conditions. Other forms of laminating include leather laminating and membrane laminating, which combines press laminating, edge folding, trimming.

Request for a quote

FRIMO GROUP GMBH

Germany

The combination of multiple technologies/procedures in one step is called OneShot technology. Semi-finished products (e.g. renewable raw materials such as natural fibers) and decorative materials (e.g. textiles) have to be handled in one production step to finish a component, such as a door panel. FRIMO has developed a modular system that allows for simple and customized configuration of a OneShot plant with all necessary tools. The following units can be integrated into such a plant: feeding station, heating station, calibrating station, material assembly station, press with OneShot tool, part-removal station.

Request for a quote

SYSKOMP GMBH - EMICO

Germany

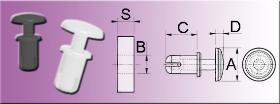

These rivets can be brought into the right position with one turn. No tools required! Mountable by the press of a finger. Material: PA 6 , UL 94 V-2 Colours: last digits 600 = white last digits 699 = black Further types on written request.

Request for a quote

GEISSEL

Germany

wege® - the flexible cable gland system in brass, stainless steel and plastic. wege® M Pressing-screws. Material: brass nickel-plated, thread: M12-M63, PG7-PG48

Request for a quote

GEISSEL

Germany

wege® - the flexible cable gland system in brass, stainless steel and plastic. wege® M Pressing-screws with strain relief. Material: brass nickel-plated,screws: stainless steel, thread: M12-M32, PG9-PG48

Request for a quote

GEISSEL

Germany

wege® - the flexible cable gland system in brass, stainless steel and plastic. wege® M Pressing-screws with strain relief. Material: brass nickel-plated,screws: stainless steel, thread: M12-M40, PG7-PG48

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

D 5 Prophit High Temperature Gasket of Expanded Flexible Graphite with and without reinforcements Characteristics Temperature range in inert environment up to +3000 °C (attention: reinforcement inserts cause temp limits) Permanent elasticity, resilience approx. 10 % Non ageing - does not contain binding compounds High pressure resistance Radiation resistance and excellent media resistance Main application Flanges Sight glasses Valve bonnets Pipe flanges Suitable for Chemical industry Petrochemical refineries and steam production Pharmaceutical industry Power plant technology Paper industry Sugar industry Form of delivery Sheets or custom die cut rings With inner or/and outer crimp: mat. 1.4571 0.15 mm thick, seamless pressed Other materials and designs on request.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ECKOLD GMBH & CO. KG

Germany

With the ECKOLD insertion system, nuts, studs and bolts can be pressed into almost any material, especially in the automated production. The servo motor-driven system can be configurated for stationary or robot-guided use. This offer includes: Servo motor-driven insertion system • Insertion frame, throat of approx. 700 mm Stroke 150 mm Press force max. 58 kN Positioning accuracy +/- 0.02 mm Stroke speed max. 150 mm/s • Servo motor-driven • Feeding unit • Separator • Frame • Control cabinet incl. visualisation software ECKOLD VISU • Tool holders Tools are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer!

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

MSE stainless steel filter presses comply with the high hygiene and purity standards both in design and processing. With the stainless steel filter press, all components in contact with the product are covered with high-quality stainless steel. This also provides optimum protection against corrosion. FDA-COMPLIANT SOLID-LIQUID SEPARATION WITH THE MSE STAINLESS STEEL FILTER PRESS A large number of materials with different properties are used in the food sector in particular. Here, especially care must be taken to ensure that no ingredients are released into the food. The law stipulates a FDA certification for this. Accordingly, all materials used must be FDA-certified. The FDA certification stands for high purity and durability. Each component such as the filter plates, filter cloths and piping systems complies with the FDA guidelines. This contributes to high hygiene and safety requirements.

Request for a quote

K-A-L-M BEFESTIGUNGSSYSTEME GMBH

Germany

The wedge anchor is hammered into the borehole, with the expansion clip resting against the borehole wall due to its internal stress. When the nut is tightened, the cone pulls into the expansion clip, spreads it and presses it against the building material.

Request for a quoteResults for

Pressing materials - Import exportNumber of results

21 ProductsCountries

Company type