- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision optics

Results for

Precision optics - Import export

MICRO-EPSILON

Germany

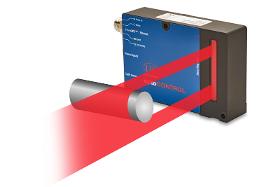

Optical micrometers from Micro-Epsilon operate according to the transmitted light principle (ThruBeam micrometer). Here, the transmitter produces a parallel light curtain that is transmitted via a lens arrangement into the receiver unit. The beam is interrupted if an object is in the light path. The resulting shadowing is detected by the receiving optics and output as measurement value. Most optical micrometers are used for dimensional measurements in production, machine monitoring and quality assurance. Parameters such as diameter, gap, height and position are detected with high accuracy.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

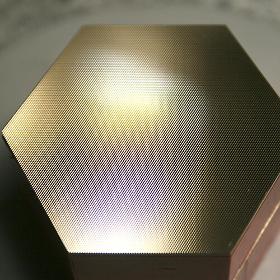

With the chip-removing microstructuring of metal surfaces, LT Ultra offers the right manufacturing technology for the production of embossing tools with optical surface qualities that allow economical replication in large numbers. Examples of microstructuring are the production of microfluidics or microlenses on our ultra-precise multi-axis machines. We can manufacture the structures directly in various materials such as brass, chemically deposited nickel or in selected hardened steels.For the replicating production of optical components, ultra-precise mold inserts made of steel are of particular interest due to their very long service life compared to other materials. In order to avoid the final polishing, which often leads to an undesirable change in shape or which is impossible due to a high structure density, LT Ultra offers ultrasound-assisted machining of steels with geometrically defined cutting edges made of monocrystalline diamond.

Request for a quote

MICRO-EPSILON

Germany

The optoCONTROL 2520 is a compact laser micrometer with integrated controller. A high resolution, model variant with measuring ranges of 46 mm and 95 mm as well as variable mounting distances allow a wide range of applications in quality monitoring and production control. The measurement object can be placed at any position within the light curtain and the distance from transmitter to receiver can be freely selected.

Request for a quote

MICRO-EPSILON

Germany

The optoCONTROL 2700 is a compact LED micrometer for the precise measurement of diameter, gap, edge and segment. The micrometer is characterized by its high accuracy with a measuring range of 40 mm. As the controller is integrated in the receiver, the cabling and installation work is reduced to a minimum. Thanks to the active inclination correction, objects tilted by up to 45° are also detected extremely precisely. The configuration is performed conveniently via the web interface and enables the parameters set up of video signal, filter and different measuring modes. In set-up mode, a shadow image can be used for simple alignment of the measuring object. The excellent price-performance ratio rounds off the service package.

Request for a quote

MICRO-EPSILON

Germany

The optoCONTROL 1200 is based on the principle of light quantity measurement. The compact laser micrometer has all the evaluation electronics integrated in the case and the mounting is very flexible. High dynamic applications can be measured due to the measuring rate of 100 kHz.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Control of thread density / course density / basis weight The Famacont PMC determines the thread density by means of a non-contacting, optoelectronic or imaging process. With the optoelectronic process individual threads or courses pass the sensor and are projected onto the photocell using a precision optical lens. The resulting frequency is proportional to the thread count. A high-resolution camera is used with the imaging process. The image is analysed with using suitable software (FFT analysis). Both, the thread count in weft and warp direction can be determined here with maximum precision.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication, cleaning and protection of bright metal surfaces, e.g. of precision machine tools, measuring equipment, mechanisms in precision mechanics and optics, of precision instruments Can be used at machine elements of all types, for example sliding parts or slideways, at threads, locks, hinges, joints, drives Versatile use over the full range of care, conservation and maintenance applications Advantages and benefits Highly effective due to good wetting, dissolving and protective ability Good creep properties Behaves neutrally with respect to plastics, elastomers and paints Good protection against corrosion-causing moisture and wetness Resin and acid-free OKS 700 is also suitable for use with the refillable Airspray system

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication, cleaning and protection of bright metal surfaces, e.g. of precision machine tools, measuring equipment, mechanisms in precision mechanics and optics, of precision instruments Can be used at machine elements of all types, for example sliding parts or slideways, at threads, locks, hinges, joints, drives Versatile use over the full range of care, conservation and maintenance applications Advantages and benefits Highly effective due to good wetting, dissolving and protective ability Good creep properties Behaves neutrally with respect to plastics, elastomers and paints Good protection against corrosion-causing moisture and wetness Resin and acid-free OKS 700 is also suitable for use with the refillable Airspray system Also available as spray version OKS 701

Request for a quote

INGENERIC GMBH

Germany

The use of aspheres and acylinders offers substantial advantages: minimization of aberrations, increase in efficiency, reduction of optical elements and weight of the optical system. With its unique molding technique, INGENERIC combines cost effectiveness with highest serial precision. Molded optics can be structured/curved on one or both sides with a large degree of geometrical freedom and a flexible lateral contour. The lateral dimensions range approximately from 2.0 mm to 5.0 mm. Structures in the sub-millimeter range are feasible. Acylinders with larger dimensions are manufactured by INGENERIC’s well-proven grinding and polishing technology. The dimensions of these large acylinders can reach 60.0 mm in length and 120.0 mm in height. This technology is particularly adept for the manufacture of fused silica optics for applications with high power densities.

Request for a quote

INGENERIC GMBH

Germany

High-precision Aspheres and Acylinders The use of aspheres and acylinders offers substantial advantages: minimization of aberrations, increase in efficiency, reduction of optical elements and weight of the optical system. With its unique molding technique, INGENERIC combines cost effectiveness with highest serial precision. Molded optics can be structured/curved on one or both sides with a large degree of geometrical freedom and a flexible lateral contour. The lateral dimensions range approximately from 2.0 mm to 5.0 mm. Structures in the sub-millimeter range are feasible. Acylinders with larger dimensions are manufactured by INGENERIC’s well-proven grinding and polishing technology. The dimensions of these large acylinders can reach 60.0 mm in length and 120.0 mm in height. This technology is particularly adept for the manufacture of fused silica optics for applications with high power densities. Advantages superior image quality freedom of design free form surfaces integrated...

Request for a quote

MICRO-EPSILON

Germany

During the production of inner liner, the thickness profile of inner liner material is measured immediately after the calender using systems of the thicknessCONTROL TIP series. Accurate precision of the non-contact optical system ensures high quality and security of the product produced. Sensors belonging to the thicknessCONTROL RTP series can also be applied for this application.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For lubrication points of all kinds as slide ways, spindles, geared parts of the electronic, precision engineering and optical equipment, temporarily or permanently exposed to extreme low temperatures like in arctic climates or cold storages Roller bearing lubrication of high-speed bearings, e.g. spindle bearings, miniature or precision bearings in machine-tools or textile machines, measuring equipment, electric motors of control technology and precision mechanics Advantages and benefits Dynamic light noise proofed long-term lubrication grease Best use at arctic conditions and very high speed High efficiency through optimal formulation Multifunctional application beside the regular range of performance for greases Efficient through economical application No nameable change of consistency at low temperatures or high speeds and accordingly temperatures

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

In the basic version the MMC 5000 consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. A Y-axis is available as an option. Another useful accessory is a second milling spindle, used perpendicular to the first one, thus allowing for the machining of two sides of a workpiece to perpendicularity in one setup. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement, machine interferometers and other sensors for insitu measurement of workpiece shape and roughness, make the MMC 5000 machines an effective tool. In addition, various sensors are available for measuring of the workpiece geometry and surface quality during the manufacturing process.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The MMC 600/900 is the basis for a series of machines that, via several accessories and options, can be fully customized to individual needs. In the basic version the machine consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. Several accessories like a Y-axis, an A-axis and/or C-axis are available, thus expanding the range of machinable parts to microstructures, lenticular structures, spheres, polygons and so on. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement and even machine interferometers for insitu measurement of workpiece shape, make the MMC 600 and 900 machines an effective tool. Besides further accessories, there is the possibility to make customized solutions, to adapt the machine to your needs.

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

Sturdy, optical precision instrument to be attached on machines, control devices, measuring devices and equipment.

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

The Centring Microscope ZM1 is a sturdy, optical precision instrument to be attached on machines, control devices, measuring devices and equipment. The high quality, coated optics and the complete metalic design ensures a high durability. Eyepiece with diopter compensation and crosshair with concentric circles Straight tube, 45° or 90° image redirection available Versions with prism for image erection Special designs are available upon request.

Request for a quote

BRUKER OPTICS GMBH & CO. KG

Germany

The IFS 125HR is the ultimate instrument for the high resolution IR spectroscopy Outstanding results in your laboratory In absorption or emission mode, the IFS 125HR can resolve highly complex spectra into discrete lines for recognition and spectral assignment. Outstanding resolution across the entire spectrum Resolved linewidths of < 0.0009cm -1 Broad spectral range: from 5cm -1 in the far-IR to >50,000cm -1 in the UV Double-sided interferogram acquisition (option) Symmetric line shapes - due to high precision optics Easy range change - every experiment can access different sources and detectors without breaking vacuum. A total of 4 sources and 6 detectors can be accessed through each of two different sample compartments

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NANOSYSTEC GMBH

Germany

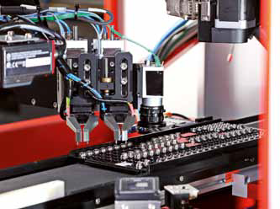

The fully automated assembly station VersaGlue takes components, such as lenses or dies from a loading area and mounts them by epoxy gluing with UV or thermal curing. The large work area of up to 1000 mm x 1000 mm provides space for the positioning of device trays and support systems. The parts are presented manually or fully automated. Feeders or stop-motion conveyor belts bring the parts to the working area and collect the finished product. The VersaGlue processes optoelectronic elements like VCSELs, photo diodes, laser dies and micro optics with highest precision while the passive placement of fiber ribbon cables is another major application.Thorough design and continuous optimization of all functional groups lead to superior mechanical stability. Mechanical references with tight tolerances provide a repeatable manufacturing operation from device to device.

Request for a quote

TOPTICA PHOTONICS AG

Germany

TOPTICA's high-power single-frequency diode lasers are ideal coherent laser sources for a multitude of demanding applications, including lithography, optics test & inspection and holography. These lasers pave the way to manufacture high-quality optics for Augmented Reality (AR), Virtual Reality (VR) or Mixed Reality (MR). For example, ultra-precise optical gratings are easily produced with these laser systems to fabricate hologram projections or holographic safety features.

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

The premium dual channel thermopile has been specifically designed for demanding measurement applications for the analysis of N2O (nitrous oxide) in environments from -20 to 85 °C. It achieves an exceptionally high detectivity of up to 6.27*10^8 cm√Hz/W and a sensitivity of up to 171 V/W. This signal quality is comparable to pyroelectric detectors. The infrared filter with a CWL of 4525 ± 20 nm and a HBW of 83 ± 6 nm is precisely matched to the optical characteristics of the target gas. Medical technology, especially patient and anesthetic gas monitoring, are typical application fields for the MTS2SENS200 nitrous oxide. The integrated thermistor for reference temperature determination and an additional reference channel (CWL: 3910 ± 28, HBW: 70 ± 10 nm) complete the detector. The dual detector MTS2SENS200 nitrous oxide is based in the core on 2 chips with 200 bismuth-antimony/antimony thermocouples each.

Request for a quoteResults for

Precision optics - Import exportNumber of results

21 ProductsCountries

Company type

Category

- Sensors (5)

- Silicones (3)

- Measurement - Equipment & Instruments (2)

- Laboratory equipment and instruments (2)

- Milling - steels and metals (2)

- Optical measuring equipment (1)

- Heat detectors (1)

- Embossing machine tools (1)

- Import-export - electrical and electronic equipment (1)

- Textiles - Machines & Equipment (1)