- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision milling

Results for

Precision milling - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC milling is an automated machining process used to manufacture 2D and 3D parts by removing material from raw stock . This process is used in various industries such as aerospace, automotive, and industrial equipment to produce a wide range of parts, including gears, shafts, brackets, and housings .The precision and accuracy of CNC milling make it an ideal process for producing complex and high quality parts .It can produce parts of nearly any shape from soft metals like aluminum, harder metals like steel, and plastics such as acetal...

Request for a quote

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

Wissner’s highly dynamic GAMMA series is your HSC milling center for the most precise and fastest machining of your parts! Whether 3-axis, 4-axis or 5-axis – our modular concept allows customization to ensure your individual, machining tasks are achieved. The machine with a mono-block portal design is extremely compact and requires minimal space. The GAMMA series machines use Wissner’s FEM optimized machine frame with an exceptionally stiff and robust machine housing. The entire portal construction including side walls, the machine bed, and the traverse are built in one piece. Conical, tapered portal walls, a technology that Wissner initially introduced to this machine category, ensures a solid, vibration-free connection between the portal and the machine bed.

Request for a quote

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

WiTEC Performance is the perfect solution for the most precise and fastest machining of your sheet material! The Performance is the flagship solution of the WiTEC machine family. A machine concept based on a FEM optimized design, built using premier precision components, and equipped with linear magnet motor technology, the Performance is able to achieve the highest levels of precision and speed, up to 80m/min! Thanks to the combination of Wissner’s innovative and patented hold&press Technology and sophisticated Vacuum System, you can mill even the smallest parts all the way through the finishing cut-out! No need for any adhesive paper or foil, no need for leaving connector tabs, and no deburring or cleaning is necessary! The ready-finished parts will go directly from the machine table to the end customer!

Request for a quote

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

WiTEC Basic - the perfect, allrounder machine for the most precise and fastest machining of your sheet materials! Equipped with an FEM optimized machine design, premier precision components, and using powerful Servo Technology, the WiTEC router is capable of achieving top milling speeds and delivering top precision results. Thanks to the combination of Wissner’s innovative and patented hold&press Technology and sophisticated Vacuum System, you can mill even the smallest parts all the way through the finishing cut-out! No need for any adhesive paper or foil, no need for leaving connector tabs, and no deburring or cleaning is necessary! The ready-finished parts will go directly from the machine table to the end customer!

Request for a quote

STARRAG GMBH

Germany

The Bumotec s191V is the combination of proven Swiss made mechanics and stateoftheart CNC control and drive technology. With the CNC Bumotec s191V mill / turn center, precise and complex components can be produced via 5axis machining. Thanks to its stable mechanical concept and its linear drive technology, accuracies of just a few microns can be achieved. The integration of an individually adaptable automatic workpiece change unit, allows the machine to be used for one off prototypes or to run so called «unmanned shifts» without personnel. Many different configurations are available with three to five axes of machining capacity. The thermal stabilization unit almost eliminates warmup cycles when starting or after machining interruptions. Features Linear driven motors and directdriven rotation axis High speed spindles (maximum 40,000 rpm) Smart combination of turning and 5axis machining High thermal stability Automatic tool changer for 90 HSK40 tools

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

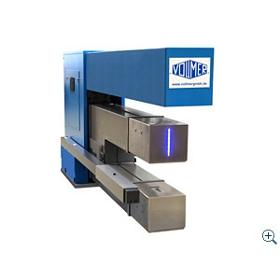

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The new standard for precision and speed With the new VTLG Series laser systems, Vollmer is giving strip thickness measurement new impetus: They combine the highest precision with rolling mill-oriented design. Thanks to their unique measuring method, they are suitable for use in cold rolling mills. With a measuring precision of ± 1 µm and scanning rate of up to 80 kHz, they offer the precision and speed necessary for the control of the strip thickness. VTLG systems are the only laser gauges to measure the strip thickness during rolling in the mill, thus opening up completely new possibilities in production and quality assurance for our customers. As with our contact gauges, they measure the thickness irrespective of the alloy – ideal preconditions for use in the rolling mill, but also on the annealing line, in the finishing section, on the strip edge miller or in the steel service centre.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The ERM scale drums are available in two completely different design types, appropriate for their use in different installations: The TTR ERM 2x00 scale drums for precise axes in turning and milling applications The TTR ERM 2x04 and TTR ERM 2x05 scale drums for spindle applications Furthermore, various grating periods are available for the scale drums, depending on the speed and accuracy requirements.

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

Multitasking machines for combined, precise milling, turning, and grinding of complex workpieces. Unique ergonomics and user-friendliness for optimum operation and work processes thanks to low machine table with integrated vertical rotary table and open access to the work area. Optimal machine concept for the production of single workpieces and series production. - Machining of complex workpieces in one clamping operation Longitudinal (X): 2,500 – 4,000 mm Vertical (Z): 1,250 – 1,800 mm Cross (Y): 1,200 – 1,500 mm NC-rotary table: Ø 1,250 – 2,000 mm

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

The SORALUCE KB-150-W series is a modern table-type horizontal boring machine for efficient multi-face machining of large and precision workpieces with weights of up to 40,000 kg. The heavy cast iron design and INA linear roller guide systems guarantee maximum stability and precision. The automatic milling head changing system provides exceptionally high flexibility thanks to the automatically lowering milling heads for machining at any angle. Longitudinal (X): 3,000 – 5,000 mm Vertical (Y): 2,600 – 3,200 mm Cross (Z): 2,000 – 5,000 mm

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

Technical information: PCD, CBN and diamond coated milling cutters are best used for the machining of non-ferrous metals, cast materials and special materials. Polycrystalline diamond (PCB) is a synthetic, extremely hard composite mass of diamond particles randomly oriented in a metal matrix. It is manufactured under high pressure and temperatures from selected diamond particles. Because of its fundamental hardness, CBN makes it possible to machine steels with hardnesses up to 70 HRC. The ability of CBN to withstand high speeds and feed rates, along with its good tool life, stable inserts and a precision milling machine guarantee unequalled process reliability, performance and cost effectiveness.

Request for a quoteResults for

Precision milling - Import exportNumber of results

11 ProductsCountries

Company type