- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision machining

Results for

Precision machining - Import export

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

A flow valve is a critical component in various systems where the regulation of fluid flow is necessary. It’s designed to control the rate at which fluid passes through a system, ensuring that the flow matches the requirements of the application.Flow control valves are essential in industrial usage, hydraulic systems, and pneumatic systems. They play a crucial role in regulating the flow of fluids, ensuring optimal performance and efficient operation of machinery and equipment. Control valves can be actuated in various ways, including pneumatically, hydraulically, or with electric motors. Some valves, known as automatic control valves, do not require an external power source and operate solely on fluid pressure.When selecting a flow control valve, it’s important to consider factors such as flow rate and pressure requirements, material compatibility, and environmental conditions.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are accessories for precision machining.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used for precision machine parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material and create the desired shape. A wide variety of materials can be used in CNC turning, including:Aluminum, brass, bronze, copper, hardened metals, precious metals, stainless steel, steel alloys,ABS...

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Precision machine screw fittings.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Accessories used for furniture fitting parts,connector parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The stainless steel used for precision machine.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

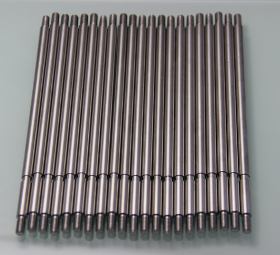

Custom pins for precision machinery.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These accessories use for precision machinery parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

these screws are used in different machine.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The accessories of panel.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Mechanical parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The stianless steel shafts, used in many fileds like construction manufacturing industry.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in valve.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel processing.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories apply for the precision machine,which were made by copper.Process by the CNC Turning machine.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Automobile brake parts,High precision CNC machine parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Camera precision aluminum cavity.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

EWS quality now available for Swiss-type lathes. This new development in driven tools is EWS's response to many customers' requests. The tool systems may appear straightforward at first sight, but their simplicity belies their performance. The design concentrates on the mounting and the spindle concentricity. The requirement profile was developed jointly with an American medical technology company which uses very small drill bits and requires extreme concentricity properties. The spindle bearing technology used with labyrinth seals sets new standards in this field, and is associated with a long service life. Provision has already been made for service. The service centres in Germany, China, Korea and the USA have already been trained in the system and are ready to respond without delay. Third-party brands can also be serviced there at any time. Download catalogue: PDF

Request for a quote

ING. KURT SCHADE GMBH & CO. KG

Germany

With our modern CNC boring machines, CNC milling machines and CNC lathes we work on steel construction components and process forgings and castings into precision components for mechanical engineering. Our cutting machine operators work precise on parts that are up to 10 meter long and weigh 25 t - with an accuracy of 0.01 millimeters. This is how customized mechanical engineering elements are created, such as: - wind power components - press stand - gear housing for mining ... The machining technicians create the individual CNC programs together with our CAD specialists directly on the CNC machines. An integrated management system and the uniform control concept from Heidenhain guarantee a high degree of flexibility; all CNC machines for heavy-duty machining are networked and access a central data pool. This is how we guarantee you fast programming and set-up times, absolute repeatability and adherence to schedules.

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

Features – 4-pole rotor with resin bonded NeFeB-magnets – 3-phase winding in delta-connexion – 3 inside hall sensors for rotor position detection – Housing made in aluminium – End shields in precision machined aluminium parts – Ballbearings on both sides electronics

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

Features – 4-pole rotor with resin bonded NeFeB-magnets – 3-phase winding in delta-connexion – 3 inside hall sensors for rotor position detection – Housing made in aluminium – End shields in precision machined aluminium parts – Ballbearings on both sides

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

Features – 4-pole rotor with resin bonded NeFeB-magnets – 3-phase winding in delta-connexion – 3 inside hall sensors for rotor position detection – Housing made in aluminium – End shields in precision machined aluminium parts – Ballbearings on both sides electronics

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

Features – 4-pole rotor with resin bonded NeFeB-magnets – 3-phase winding in delta-connexion – 3 inside hall sensors for rotor position detection – Housing made in aluminium – End shields in precision machined aluminium parts – Ballbearings on both sides

Request for a quote

KÄHLIG ANTRIEBSTECHNIK GMBH

Germany

Features – 4-pole rotor with resin bonded NeFeB-magnets – 3-phase winding in delta-connexion – 3 inside hall sensors for rotor position detection – Housing made in aluminium – End shields in precision machined aluminium parts – Ballbearings on both sides

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers an extensive range of mobile equipment for cutting and welding metal. Our products are designed to offer the highest precision and flexibility wherever they are needed. From pipe cutting devices to hand-held flame cutting machines to portable oxy-fuel technology - we have the solution for your requirements. RSV pipe cutting devices Our mobile pipe cutting devices enable the simultaneous cutting and beveling of steel pipes. Thanks to the quick-clamping device, they can be fixed in any position, offering maximum flexibility and efficiency. The cutting torch can be rotated by 45°, adjusted in height and sideways and can optionally be motorized. Hand-held flame cutting machines ZINSER's mobile hand-held flame cutting machines are designed for daily use. They offer precise and reliable cuts with maximum user-friendliness. ZINSER oxy-fuel technology ZINSER has been involved in the economical use of acetylene and other gases for over 100 years.

Request for a quote

ZINSER GMBH

Germany

High-precision plasma cutting machines from ZINSER - efficient cutting solutions for all applications ZINSER GmbH offers a wide range of high-precision plasma cutting machines that are known for their outstanding cutting quality and efficiency. Our systems are specially designed to cut mild steel, stainless steel and aluminum with the highest precision. Thanks to the latest technology and a robust design, our plasma cutting systems ensure maximum productivity and reliability in industrial production. ZINSER 4025B / 4125B / 4026B / 4126B These premium plasma cutting machines offer excellent cutting quality and reliability for demanding applications. They are ideal for cutting thick and thin materials and are suitable for both simple and complex cutting tasks. ZINSER 2315 / 2325 / 2425 / 2426 Our economical plasma cutting machines offer a cost-effective solution without compromising on quality.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

Traverse path: 800 x 900 x 600 A axle ± 140° C – axle 360° (endless) High precision machining centre in gantry construction All axles are double-equipped with motor and linear scales Zero point clamping system

Request for a quoteResults for

Precision machining - Import exportNumber of results

60 ProductsCountries

Company type

Category

- Electric motors - dC (5)

- Milling - machine tools (4)

- Wrapping machines (4)

- Connectors, electronic (3)

- Cutting - machine tools (2)

- Cutting - steels and metals (2)

- Adjustment - machine tools (2)

- Automobiles (2)

- Construction - Machines & Equipment (2)

- Inductive sensors (2)

- Industrial valves, operating equipment (2)

- Vacuum cleaners - industrial (2)

- Machine tools, metal machining - parts and accessories (1)

- Mechanical engineering - custom work (1)

- Bridges - construction (1)

- Cameras, photographic (1)

- Foundry machines - centrifugal (1)

- Frames and mountings, photograph (1)

- Furniture for kitchens (1)

- Grids, gratings and wire mesh (1)