- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pneumatic motors

Results for

Pneumatic motors - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

A flow valve is a critical component in various systems where the regulation of fluid flow is necessary. It’s designed to control the rate at which fluid passes through a system, ensuring that the flow matches the requirements of the application.Flow control valves are essential in industrial usage, hydraulic systems, and pneumatic systems. They play a crucial role in regulating the flow of fluids, ensuring optimal performance and efficient operation of machinery and equipment. Control valves can be actuated in various ways, including pneumatically, hydraulically, or with electric motors. Some valves, known as automatic control valves, do not require an external power source and operate solely on fluid pressure.When selecting a flow control valve, it’s important to consider factors such as flow rate and pressure requirements, material compatibility, and environmental conditions.

Request for a quoteHASPA GMBH

Germany

These are flexible shafts with cylindrical pin or thread to connect to: Drilling machines, pneumatic motors, lathes, cutters, straight grinders, angle grinders, other electric- or pneumatic driving units

Request for a quote

FLUX-GERÄTE GMBH

Germany

For driving the FLUX pump a wide range of electrical to pneumatic motors is available. Even if you work in hazardous areas or with flammable liquids. Depending on the application, different pumps can be driven by different motors. Thus, the output of a drum pump depends, among other things, on the power of the motor. Here you will find the most economical and safest drive solution for your application. Battery motor: FBM-B 3100 Commutator motors: FEM 3070 FEM 4070 F 457 F 458 F 460 Ex Compressed-air motors: F 416 Ex FPM

Request for a quote

GSW SCHWABE AG

Germany

Strong plasmaburned back plate provides smooth and straight operation Removable and adjustable hub disk Fast and precise expansion via bevel gear with exceptionally wide ranges, allows clamping of all internationally common coil sizes From 1000 kg capacity equipped with lever type expansion Alternatively with guide rod coil fixation instead of expansion system (mainly for pallets) Pneumatic hold down arm Motorized pivoting Electropneumatic brake system Larger mandrel segments Traveling feature Different loading heights Various expansion ranges Different back plate sizes Loop control systems

Request for a quote

PRESSTA EISELE GMBH

Germany

Fully automatic operation cutting of aluminium and non-ferrous metal NC Control with touch screen display 5,7” Piece counter showing target/actual number of pieces Piece multiplier when cutting bundles Indication of cycle time Multiple feed device – max feed 3.250mm Table separation before the saw blade retracts so the profile is not touched by the saw blade Electronic material feeder, ball screw spindle and servo motor incl. pneumatic horizontal and vertical clamps Float mounting feeder to balance bend profiles Waste piece from 85mm Reducer of clamping pressure horizontal and vertical Cycle spray mist device with level indicator and automatic stop Cut-off length from 3mm Automatic cut-out when bar is finished Technical Data: Motor up to 18,5kW, S 6 40%, 400 V, 50 Hz, 2850 R.P.M. r.p.m. infinitely adjustable Saw blade speed 3.500 – 5.800 R.P.M Saw blade Ø 400mm Profile width max 200mm height max 120mm

Request for a quote

GSW SCHWABE AG

Germany

Motorized rotation Hydraulic wedge type expansion Highend arbor with double bearing Extremely stiff design SHDH Series PullOff Reel with manually adjustable brakes SHDR Series Payoff Reel with threephase motor Pneumatic or hydraulic hold down arms Electromotive or hydraulic traveling feature w optional automatic centering Hydraulic coil car and fullsize back plates Conical keeper rolls w optional motorized travel Larger mandrel heights and segments Vectorcontrolled drive systems for heavy coil weights Servo drive and control systems, etc.

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 566 2/2-way globe control valve has a body with an integrated control mechanism which can be controlled by various operator types. In addition to a pneumatic version, manual and motorized versions are also available. The GEMÜ 566 valve was specially developed for the control of small quantities and enables flow rates from 63l/h to 2500 l/h. —Control of liquid media from 63 l/h to 2500 l/h —Linear or equal-percentage control characteristic options —Three operator types selectable (manual, pneumatic, motorised)

Request for a quote

ASP GERMANY

Germany

The very different requirements created by diverse welding techniques mean that specific products have to be specially developed. The industrial fabrics we use have specific coatings that leave the cover flexible but resistant to spatter and weld splashes. Their para-aramid base has excellent mechanical strength. Production tooling protection is a necessity. ASP offers a wide range of protective covers for all types of welding guns, regardless of the welding technology involved (pneumatic, hydraulic or electric motor).

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This production cutting machine is available as a manual and as a pneumatic variant. Its cutting motors ensure optimum cutting results thanks to their unique minimum vibration. 4.6 kW drive. For hydraulic hose assemblies up to 2” and industrial hose assemblies up to 4”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Embossing punching is an important technique in the automated production of car parts, guided by robots. A laser system with a sensor harness measures the car body and its machining plane so that the embossing depth can be determined with maximum accuracy. The car body part is then embossed accordingly and all necessary holes are punched. Embossing punching is used for the fixture of headlights, bonnets, sliding roofs, boot lids and locks as well as wings. Our embossing punching machines are suitable for single-layer steel and aluminium sheet metal. This offer includes: • Embossing punching frame (assembly elements or components can be perfectly aligned to a mating part of different dimensions) • Handling: robot-guided via defined interfaces (mechanical, electrical, pneumatic) • Servo motor-driven Tool inserts and measurement are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

Domes produced with ECKOLD machines in automotive industry make sure that there is only a minimum offset between the securing screws and the surrounding metal. ECKOLD machines can produce two or even three domes in a single process. Our dome embossing machines are suitable for both single and double sheet steel or aluminium parts and come with a hydro-pneumatic or servo motor drive system. With our machines, domes can be embossed without preliminary holes (even when combined with final hole punching for a defined diameter). This offer includes: Dome embossing frame Embossings: 1 piece/stroke Embossing geometry: according to data set Drive: pneumohydraulic Mechanical interface: support stand Embossing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. We optionally offer hydraulic or servo motor drives as well as multiple embossings/stroke.

Request for a quote

PROXOMED® MEDIZINTECHNIK GMBH

Germany

Technical data Dimensions (L/W/H) 121/92/164 cm Total weight 370 kg Equipment Continuous seat height adjustment via pneumatic springs or electric motor (optional) Laser pointer for the correct positioning of the rotation axis Continuous adjustment of the hip stabilizer for optimal pelvic stabilization (seated position) Continuous height adjustment of the lateral upper body stabilizer (seated position) Continuous adjustment of lateral upper body stabilizer for optimal fixation (seated position) Adjustment of the start position in 10° increments Very fine weight gradation in 1 kg increments Measuring sensor for isometric measurements Measuring sensor for measurement of mobility Protective panel made of frosted glass Options Pre-installed network equipment in compliance with the German Medical Devices Act (Medizinproduktgesetz) Proxotrain tergumed module Proxotrain Info point Computer trolley

Request for a quote

PROXOMED® MEDIZINTECHNIK GMBH

Germany

Technical data Dimensions (L/W/H) 126/150/164 cm Total weight 400 kg Equipment Continuous seat height adjustment via pneumatic springs or electric motor (optional) Continuous adjustment of footrest (seated position) Continuous height adjustment of the knee stabilizer Continuous adjustment of knee stabilizer for optimal fixation (seated position) Continuous adjustment of pelvic stabilizer (seated position) Continuous adjustment of shoulder stabilizer (seated position) Adjustment of the start position in 10° increments Very fine weight gradation in 1 kg increments Rotatable and tiltable SmartPanel with training software Measuring sensor for isometric measurements Measuring sensor for measurement of mobility Protective panel made of frosted glass Options Pre-installed network equipment in compliance with the German Medical Devices Act (Medizinproduktgesetz) Proxotrain tergumed module Proxotrain Infopoint Computer trolley

Request for a quote

PROXOMED® MEDIZINTECHNIK GMBH

Germany

Technical data Dimensions (L/W/H) 115/136/164 cm Total weight 370 kg Equipment Continuous seat height adjustment via pneumatic springs or electric motor (optional) Laser pointer for the correct positioning of the rotation axis Continuous height adjustment of the lumbar stabilizer via pneumatic springs Continuous adjustment of footrest via pneumatic springs (seated position) Continuous height adjustment of the knee stabilizer (seated position) Continuous adjustment of the knee stabilizer via pneumatic springs (seated position) Continuous adjustment of the lever bar length Adjustment of the start position in 10° increments Very fine weight gradation in 1 kg increments Rotatable and tiltable SmartPanel with training software Measuring sensor for isometric measurements Measuring sensor for measurement of mobility Protective panel made of frosted glass Options Pre-installed network equipment in compliance with the German Medical Devices Act (Medizinproduktgesetz) Proxotrain tergumed...

Request for a quote

PROXOMED® MEDIZINTECHNIK GMBH

Germany

Technical data Dimensions (L/W/H) 115/136/164 cm Total weight 370 kg Equipment Continuous seat height adjustment via pneumatic springs or electric motor (optional) Laser pointer for the correct positioning of the rotation axis Adjustable seat angle (optional) Continuous height adjustment of the lumbar stabilizer via pneumatic springs Continuous adjustment of footrest via pneumatic springs (seated position) Continuous height adjustment of the knee stabilizer (seated position) Continuous adjustment of the knee stabilizer via pneumatic springs (seated position) Continuous adjustment of the lever bar length Adjustment of the start position in 10° increments Very fine weight gradation in 1 kg increments Rotatable and tiltable SmartPanel with training software Measuring sensor for isometric measurements Measuring sensor for measurement of mobility Protective panel made of frosted glass Options Pre-installed network equipment in compliance with the German Medical Devices Act...

Request for a quote

KLN ULTRASCHALL AG

Germany

Basically the TOOLMASTER versions vary by their tool design, their size of useable surface and the degree of automation. All versions are suitable for high temperatures and optionally equipped with fire protection engineering, which quickly separates the tool in case of energy drop or timeout. KLN also manufactures special machines adapted to your individual requirements. TOOLMASTER "Basic" as well as type HE 50/30 are standard machines. The versions "Advance", "Semi-Automatic" and "Automatic" are made with tools in sandwich design. This makes possible the handling of upper tool, hot plate element and lower tool as a compact unit. They are designed particularly for quick and frequent production changes. The HE/SA has a horizontal concept with servo-drive technology for quick and precise movements. The TOOLMASTER CC has been developed for applications with two welding tasks in one cycle. Almost all machine versions can be provided with pneumatic or servo-motor drives.

Request for a quote

BORRIES MARKIER-SYSTEME GMBH

Germany

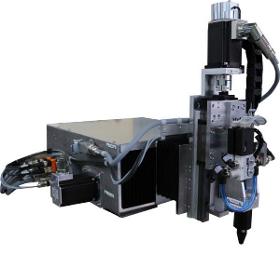

The marking unit 315 is a very well protected and highly robust device designed for 3-shift operation. All components of this coordinate unit have been developed for regular use and are continuously tested to ensure a constant quality. The set of a marking head and a controller is integrated as a built-in unit by system producers for direct workpiece marking e.g. in transfer lines, production machines or gauging and testing stations. The pneumatic (PN) or stepping motor (SM) adjustment unit allows to forward the marking unit to the workpiece even at places which are difficult to access. Marking unit for marking processes: scribe, stylus, dot marking and DataMatrix coding (ECC200)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Pneumatic motors - Import exportNumber of results

17 ProductsCountries

Company type