- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plate filters

Results for

Plate filters - Import export

FILTERTECHNIK JÄGER GMBH

Germany

Special FTJ filter fleeces are particularly suitable as precoat or support fleece on horizontal plate pressure filters or plate filters The following precoat agents are used: Diatomaceous earth Bleaching earth Cellulose Cornmeal The FTJ nonwovens Cora®Dot and Cora®Spun effect corresponding savings on precoat agents with extremely fine filtration.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

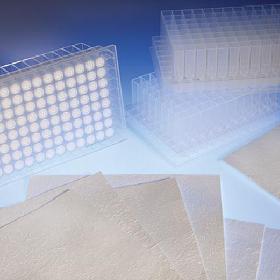

Recover filtrates and particulate retentates thoroughly and quickly Used for high recovery of filtrates and particulate retentates, POREX® deep well filter media are designed for high-throughput sample processing. Our POREX deep well filter plate media features: High sample recovery for many processing techniques including filtration, vacuum filtration, centrifugation or other positive pressure techniques Minimal contamination–Porous material structure prevents cross talk between adjacent well walls. Proprietary surface modification – Materials allow multiple functionalities or sorbent addition, including CPG, carbon C18 or C8, and media is suitable for vacuum filtration, centrifugation or other positive pressure techniques. Tested by independent laboratories - Certified pure materials ensure performance, accuracy and reproducibility. Features Certified Pure Porex™ Materials Filter Media Purity – no material additives or contaminants No Heavy Metal Interference No other...

Request for a quote

AQUACHEM GMBH SEPARATIONSTECHNIK

Germany

The filter presses from AQUACHEM of the EC Beverage series are used in the beverage industry, for example, for the filtration of selected wines. Another feature is that the filter elements are gasketed, and therefore the must or juice does not also come into contact with the ambient air. The EC Beverage series is offered as standard in the filter plate sizes 470, 630 and 800 mm.

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Easy-to-use, mobile carpet probe with surface plate, bag filter, hose and plug-in coupling for surveying pipelines, and for recording gas traces after checking the gas pipeline network with the suction process. Very light, therefore fatigue-free and easy to use in daily tasks. The wide edge of the flexible carpet probe conforms well to unevenness on the pavement surface and largely prevents the ingress of interfering gases (exhaust gases) during the inspection process.

Request for a quoteFAUDI GMBH

Germany

Advantages Parallel alignment of multiple Sieve Cylinders enables a large filtration area on limited space Higher filtration degree possible through bag inserts Area of application Applicable as pipeline and process filter Flow rate Various filter sizes and the modular design enable any required flow rate. classification number S26 Filter aid - Filtration degree 0,5 µm - 20 mm Medium low viscosity liquids, gases Filter material perforated plate cylinder, mesh, bags

Request for a quoteFAUDI GMBH

Germany

Advantages Parallel alignment of multiple Sieve Baskets enables a large filtration area Area of application For the filtration of all types of liquids; protection filter for pumps and volumeters, pipeline filter, etc. Flow rate Various filter sizes and the modular design enable any required flow rate. classification number S22 Filter aid - Filtration degree 50 µm - 20 mm Medium oil, emulsions, solvents Filter material perforated plate cylinder, mesh

Request for a quoteFAUDI GMBH

Germany

Advantages Parallel alignment of multiple Sieve Baskets enables a large filtration area Area of application For the filtration of all types of liquids; protection filter for pumps and volumeters, pipeline filter, etc. Flow rate Various filter sizes and the modular design enable any required flow rate. classification number S21 Filter aid - Filtration degree 50 µm - 20 mm Medium oil, water and solvents Filter material Perforated Plate Cylinder, Mesh

Request for a quoteFAUDI GMBH

Germany

Advantages Inline alignment of Sieve Baskets; all pressure rates and materials are possible; applicable for processes with high differential pressure; heated version available Area of application For the filtration of all types of liquids; protection filter for pumps and volumeters, pipeline filter; etc. Flow rate Various filter sizes and the modular design enable any required flow rate. classification number S11 Filter aid - Filtration degree 50 µm - 20 mm Medium oil, water and solvents Filter material perforated plate cylinder, mesh

Request for a quoteFAUDI GMBH

Germany

Advantages Simple, compact design Area of application For the filtration of all types of liquids; protection filter for pumps and volumeters, pipeline filter, etc. Flow rate Various filter sizes and the modular design enable any required flow rate. classification number S7 Filter aid - Filtration degree 10 µm - 5 mm Medium oil, water Filter material perforated plate cylinder

Request for a quoteFAUDI GMBH

Germany

Advantages Simple, compact design Area of application Various filter sizes and the modular design enable any required flow rate. Flow rate Various filter sizes and the modular design enable any required flow rate. classification number S9 Filter aid - Filtration degree 10 µm - 5 mm Medium Oil, water Filter material Perforated Plate Cylinder

Request for a quoteFAUDI GMBH

Germany

Advantages Certified Gas Separator; maintenance-free operation; for the separation of rough particles Area of application For the use at refuelling points of aviation fuel, gasoline and hydrocarbon Flow rate Various filter sizes and the modular design enable any required flow rate. classification number P55 Filter aid - Filtration degree - Medium Nitrogene, gases Filter material Perforated Plate Cylinder Mesh

Request for a quote

F.E.S. GMBH

Germany

Plate Precoat Filter are used for the fine filtration of low-viscosity oils. This cost-effective filter is a compact device designed to supply individual machines. The achievable filtration fineness is between 1 and 5 µm in NAS 3-7. The filter regeneration and cleaning of the filter discs are done manually. Advantages: Small footprint Excellent filtration results Low installation effort The filter geometry can be customized to match the machining machine (on request) Affordable price Operating Principle: Swelling: The entire tank is filled with oil. Before filtration can begin, the filter discs (1) need to be swollen with a filter aid (diatomaceous earth, cellulose, perlite). Filtration: After the precoat, the operator manually switches to filtration and directs the filtrate into the clean tank (2). The system pump can now be switched on to supply the processing machine. The achievable filtration fineness is 1 – 5 µm, depending on the filter aid used.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via pre-filters and fine filters. Spray walls and spray booths with dry separation For lower utilisation times or overspray quantities, spraying systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RTS enables individual adaptation to the respective case of need. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The entire spray wall and the drip tray are made of galvanised sheet steel. The basic version consists of a wall with a two-fold filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The first filter stage is formed by a paper filter or a baffle plate filter, consisting of two rows of galvanised sheet metal lamellae arranged one behind the other. A glass fibre fine filter arranged directly behind it represents the second filter stage. The spray wall can additionally be equipped with removable or fixed side and ceiling panels. Each version is also available with floor suction pan, available with an integrated 2-stage filter and grating cover. Accessories In addition, the spray wall can be equipped with various accessories from the Rippert product range, such as explosion-proof lights, energy-saving flaps, turntables, etc. We recommend the installation of a supply air system for the replacement of the exhausted air. Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. For faster cleaning, baffle plate filters should by sprayed with a release agent (e.g. strippable varnish) before being put into operation. Underfloor paint mist extraction With dry separation, consisting of a support structure with attached paper filter, grating cover and a suction duct with air quantity adjustment.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Designed as in-tank suction strainer elements for direct installation into suction lines of pumps; should always be installed below the minimum fluid level of the reservoir Features ▪ Available with female BSP thread (ISO 228) or female NPT thread (ANSI B1.20.1) Materials ▪ Threaded end cap made of glass-fibre reinforced Polyamide (PA) or Aluminium ▪ Lower end cap and support tube made of Steel, zinc-plated ▪ Standard filter material is Stainless Steel Mesh (125 μm); alternative micron ratings of 60 μm and 250 μm on request Consult STAUFF for alternative materials. Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Technical Data ▪ Operating temperature range: -20 °C ... +100 °C / -4 °F ... +212 °F ▪ Integrated bypass valve with an opening pressure of 0,2 bar (3 PSI) to reduce the risks of high-pressure drops that can be caused by contaminated strainer elements or high-viscosity fluids Special sizes, designs, materials and...

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

With high-quality filter tubes and PTFE diaphragms. Paint dust filters Wet painting also results in overspray. Overspray is the solid portion of the paint that is not taken up by the workpiece. According to the purpose of use, the overspray is moist and sticky immediately after release. It is captured by the exhaust air stream in the spray booth and fed to a filter. This can be, for example, a baffle plate filter, paper filter, fleece filter, glass fibre filter or also combinations of these. The adhesive effect causes the paint particles to adhere to the contact surfaces of the respective filter medium, as a result of which a good degree of separation is achieved. However, all these filters are storage filters, i.e. the filters clog up more and more during operation and cannot be regenerated. A filter exchange becomes necessary if the exhaust air rate of the spray booth falls below the minimum. This can be very time-consuming under certain circumstances and the work process must be interrupted in order to do it. To make things worse, not only must the filtered and bound paint residues be disposed of, but also the actual filter materials. Such tooling times are not justifiable for automatic, continuous or multi-layer painting processes. Continuous procedures such as automatically cleaned filters are likewise required for this. The humidity and the adhesiveness of the particles to be filtered are thereby the problem. In order to solve this problem, the paint particles should be relieved of their adhesive capability as far as possible whilst still inside the paint booth. Our patented ‘RTS-Rotation’ system is outstandingly well suited for this. The system is comprised of slowly rotating brush rollers, which take up the adhesive paint particles on the surface of the bristles and allow them to dry there. The bristles are automatically regenerated at pre-specified time intervals by combing devices that swing in at the rear of the brush rollers. The dislodged paint residues can then be removed and disposed of either manually during work breaks or automatically during operation. The degree of separation of this system is, however, insufficient to satisfy the environmental protection requirements concerning residual dust content in the exhaust air. A further filter stage is necessary for that. It must be assumed that the paint particles arriving here are to a certain extent still damp and sticky. For this we use special paint dust filters with high-quality filter tubes with PTFE diaphragms. If necessary, precoating agents (auxiliary dust) are used in order to neutralise the adhesive capability of the particles and to keep the dust layer on the filter elements permeable to air. The precoating agent is injected into the raw air pipe by means of special dosing units. The filter tubes are cleaned by means of compressed air impulse cleaning. The use of this technology requires special know-how. We have had the appropriate experience for almost ten years. The implemented plants have capacities ranging from 5,000 to 90,000 m³ /h. Because of the large number of different paint systems, individual experiments are usually necessary in our pilot plant in order to find the correct solution for the individual case.

Request for a quote

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

Vshaped arranged filter plates from closely pleated 4layer filter media composite nonwoven from electrically uncharged, organic, synthetic microfibres and activated carbon grains rugged KALTHOFF filter casing of plastic doubleworking arrester very high adsorption kinetics conditions for mounting and service optional at site

Request for a quote

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

ISO ePM10ISO ePM1 / M6F9 stable, twosided hot meltsealed filter plates closely pleated, progressivelystructured filter media synthetic, multilayer microspunbond INTERMELT pleating system rugged KALTHOFF filter casing of black plastic 25 mm flange profile high dustholding capacity resistant to high humidity arbitrary installation position enables easy installation high filter efficiency with low pressure drop

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

ISO ePM2,5ISO ePM1 / M6H13 stable, twosided hot meltsealed filter plates closely pleated filter media of homogeneouslystructured, microglass fibre paper INTERMELT pleating system rugged KALTHOFF filter casing of black plastic 25 mm flange profile low pressure drop and consistent high efficiency suitable for high airflows high level of stability and low resistance performance airflowdirection, conditions for mounting and service optional at site

Request for a quote

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

ISO e PM 10 ISO e PM 1 / M6F9 fixed, twoside filter plates hotmelt sealed closely pleated, progressivelystructured filter media synthetic, multilayer microspunbond INTERMELT pleating system composite frames of FIBER PLASTIC and 25 mm plastic flange profile low pressure drop by using optimised flow geometry increased energy efficiency increased material efficiency low weight and easy handling

Request for a quote

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

ISO ePM10ISO ePM1 / M6H11 stable, multisided sealed filter plates closely pleated, progressivelystructured filter media synthetic, multilayer micro spunbond INTERMELT pleating system rugged KALTHOFF filter casing with blue vertical struts 25 mm flange profile very high levels of mechanical strength and stability, with high efficiency burst pressure clearly above 3000 Pa high dustholding capacity resistant to high humidity arbitrary installation position enables easy installation high filter efficiency with low pressure drop

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Component for Filter Dryers The multilayer filter plates are supplied according to material requirements and permeability: Fabric (cotton, polypropylene, etc.) Filter elements made from metal Sintered plates Multi-layered plates, sintered Sterile configuration, filter elements are secured from below The existing filter plates for filter dryers can be replaced smoothly and quickly anywhere. This is also possible for machines from other suppliers. According to the customer´s requirement and machine specification the replacement of multilayer filter plates is done completely or separated in different sectors. Multilayers are available in SS 316L or Hastelloy C22 or other materials on request, available porosities 5, 10, 20 or 40 micron, other porosities on request. For machines with a bigger diameter – mainly for chemical specification – the division in different sectors offers, in case of break, the advantage that only the damaged part has to be replaced. This guarantees an...

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

COMBER Pressofiltro® Series PF 100 - PF 10000 Pharmaceutical design COMBER Pressofiltro nutsche filters or filter dryers are versatile units designed for multipurpose production facilities. To meet the demanding requirements for filters used in the manufacture of pharmaceutical ingredients, the filters are designed to meet stringent cGMP and FDA guidelines. Special properties for the customer’s benefit: Excellent cleanability using CIP systems, simple validation Openable filter base provides for good access to the filter internals for cleaning and inspection Easily interchangeable filter plates, with flat, homogeneous filter surfaces for good cleanability and inspection Multilayer and/or conventional filter materials Good drying performance with special agitator design, large heat exchange areas Double mechanical seals, externally interchangeable, dry running contacting or non-contacting lift-off type seals as well as liquid lubricated seals

Request for a quote

DELTA TECHNIK FILTERSYSTEME GMBH

Germany

Our mobile ultra fine filter system M 120 is the processing machine for larger oil volumes. Its two hard chrome-plated housings can filter up to 2.100 liter per hour of flow. The robust construction, the easy operation, and the possibility of using it in continuous operation without supervision makes it an ideal tool of a preventive maintenance strategy for large units. Even while filling new oil in larger systems it eliminates condensed water and foreign particles reliably. The high flow guarantees a short amortization time due to cost savings in fresh oil, oil changes, and repairs. 230 V-alternative 400 V motor, robust and reliable, stable gear pump Manometer for flow- and element control Pressure switch for selection setting in unattended operation 24/7 – unattended operation Pumping without filtration Flow regulation for high viscosity oils Element lifter for simple and fast element exchange

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

MSE stainless steel filter presses comply with the high hygiene and purity standards both in design and processing. With the stainless steel filter press, all components in contact with the product are covered with high-quality stainless steel. This also provides optimum protection against corrosion. FDA-COMPLIANT SOLID-LIQUID SEPARATION WITH THE MSE STAINLESS STEEL FILTER PRESS A large number of materials with different properties are used in the food sector in particular. Here, especially care must be taken to ensure that no ingredients are released into the food. The law stipulates a FDA certification for this. Accordingly, all materials used must be FDA-certified. The FDA certification stands for high purity and durability. Each component such as the filter plates, filter cloths and piping systems complies with the FDA guidelines. This contributes to high hygiene and safety requirements.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

Fully automatic filter presses are specifically designed for applications in which a continuous operation and fast cycle times are essential and therefore crucial. MSE fully automatic filter presses provide a high degree of automation while providing uninterrupted operation at the same time. FULLY AUTOMATIC FILTER PRESSES FROM MSE INCREASE PRODUCTIVITY AT THE SAME TIME REDUCING PERSONNEL COSTS The operating time of a fully automatic filter press is 24/7. The option of the simultaneous filter plate opening system, for example, helps to realise a particularly fast cake release reducing the cycle time to a minimum. The result is a high-speed filter press that allows increased production per unit area of filter. For this reason, these machines are used in applications with highly filterable products where high filtration speeds are required. These include, e.g. mining concentrates and residues.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

The hot filter press combines the standard process steps of a membrane filter press, (filtration, filter cake washing and squeezing), with the additional function of a thermal filter cake drying (TCD). As a result, all process steps are carried out in one plant, the hot filter press. Dewatering and drying of the resulting filter cake is thus done without a downstream drying process. Cost-intensive and time-consuming vacuum contact drying is therefore no longer necessary. FUNCTIONAL PRINCIPLE OF THE HOT FILTER PRESS – WITH THERMAL FILTER CAKE DRYING In contrast to the conventional method, the system consists of membrane filter plates and heat exchanger plates, which are installed alternately in a filter press. For thermal drying, hot steam and/or oil is applied to the working space behind the membrane and the filter cake is thermally dried accordingly. The advantage of this process is that a high dry matter content (DM content) of over 90% is achieved.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

Membrane filter presses have a great influence on the dryness of the solid by using membrane technology in the filter plates. Compared to conventional filtration processes, it achieves the lowest residual moisture values in the filter cake. This makes the membrane filter press a powerful and the most widely used system. IF TIME AND DEGREE OF DEWATERING ARE CRUCIAL Depending on the degree of dewatering, different dry matter contents ( – percentage by weight of dry material in filter cake) can be achieved in the filter cake by squeezing with membrane plates. The range of achievable dry matter contents extends from 30 to over 80 percent. Membrane filter presses not only offer the advantage of an extremely high degree of dewatering; they also reduce the filtration cycle time by more than 50 percent on average, depending on the suspension. This results in faster cycle and turnaround times, which lead to an increase in productivity.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

Semi-automatic filter presses represent a simplified and cost effective solution for the reliable operation with respect to operation and safety measures. This type of filter press is distinguished by a special, a rail-mounted two-hand control panel. The filter press with two-hand control is used in particular when the space on site is limited or a higher degree of automation is not required. Accordingly, a conventional version of the protective device is no longer effective. REDUCED PROCUREMENT COSTS AND SIMPLE OPERATION – THE SEMI-AUTOMATIC FILTER PRESS WITH TWO-HAND CONTROL FROM MSE Based on the safety technology requirements, an intelligent two-hand control is implemented, for example, for moving the filter plates by means of automated plate shifter. This functional principle thus prevents the operator from reaching into the working area. Complicated mechanical designs including further safety measures are not necessary.

Request for a quote

AHN BIOTECHNOLOGIE GMBH

Germany

AHN offers spin columns that are designed to purify, isolate, and separate biomolecules. Each spin column comprises of a 2mL receiver tube and a 0.8mL round bottle filter tube. There are multiple filter options available such as glass fibre, polyethylene, cellulose acetate, regenerated cellulose, nylon, and polyvinylidene fluoride, to meet the diverse needs of various applications. The filter plates are designed to scale up to high throughput for a wide range of applications, including nucleic acid purification, recovery and removal of proteins, next-generation sequencing sample preparation, and chromatography clean-up. They are manufactured from high-quality virgin polystyrene in accordance with SBS standards. The microfilter plates come in an 8x12 matrix arrangement, spotted with a total of 96 wells. Each well has a generous sample volume of 1mL.

Request for a quoteResults for

Plate filters - Import exportNumber of results

32 ProductsCountries

Company type