- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plastic tray

Results for

Plastic tray - Import export

SCHOLL APPARATEBAU GMBH & CO. KG

Germany

For trapezial trays. Design: Frame structure made of anodized special light-metal-profiles, side walls made of melamine resin laminated, completely bordered with U-profile. Tray supports made of angular plastic U-profile. Tray trolleys with 1 or 2 racks. Mounted on 4 corrosion protected, ball bearing castors with distance holding rolls, 2 of them lockable.

Request for a quote

J.D. GECK GMBH

Germany

Highquality pump dispenser, made in Germany. For all Geck disinfection systems. Also available for wall mounting. Inquire now. Permanently available Made by Geck Produced in Germany Manually operated pump dispenser (handle length approx. 14 cm), with universal holder for 1,000 ml Euro bottles Material housing made of stainless steel and plastic, white Scope of delivery pump dispenser, 1,000 ml disinfectant container, fastening material for wall mounting Optional ,with wall panel including printing of pictograms hand disinfection ,Drip tray with stainless steel holder and plastic tray Contact us at any time via gesundheit@geck.de or visit our website https//www.geck.de/en/healthpreventionsystems.

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling machine for viscous products 6-lane machine with multiple product chambers for ready-to-serve meals in plastic or aluminium trays Machine performance: 40 cycles/min. 240 trays/min. 14.400 tubs/h Special features: Sterile air hood in filling area Tray magazine 2 x 6 dosing pumps with motorised individual adjustment from 0 – 500 ml Manual filling channel for insertion of products that cannot be filled 2 film applicator stations 2 sealing stations

Request for a quote

EXCOR KORROSIONSSCHUTZ-TECHNOLOGIEN UND -PRODUKTE GMBH

Germany

EXCOR VALENO Trays and Containers are made of hard plastics based on polyethylene and polypropylene and manufactured using deep-drawing or injection moulding techniques. The durability of these containers makes them the ideal choice for multiple uses, or may with narrower walls be employed as single-use packaging. The work pieces or small loads to be transported fit snugly into the containers. No additional VCI diffusers are needed since the plastic is impregnated with VCI substances. These two combined properties markedly simplify every kind of automated transport and storage process. Provided the instructions for use are followed EXCOR VALENO Trays and Containers will offer corrosion protection for up to five years.

Request for a quote

TANOS GMBH

Germany

MINI-systainer® T-Loc III completely fitted with boxes, 3-compartment deep-drawn tray and cover insert. Base tray with multicoloured removable individual boxes This combination of multicoloured boxes and deep-drawn trays offers excellent flexibility for storing small components. Multicoloured boxes and base tray are also available separately Ribbing is integrated into the base tray to ensure the individual multicoloured boxes remain in place with the lid closed. An excellent choice for sorting small components in a systainer®, such as jigsaw blades, drill bits, screws, etc. systainer® material: ABS Cover insert material: EPP moulded foam Deep-drawn tray material: PS plastic Box material: PS plastic

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

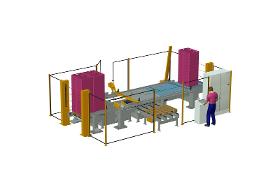

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Gentle transport of products and high performance due to continuous chain run • Intermediate buffering of several products possible • Up and down movement with same side or opposite side infeed/outfeed Vertical lifts make material flow across several levels possible and are used wherever goods need to be transported vertically - they are ideal for the vertical transport of boxes, trays, plastic containers, bundles, pallets, and bags within automatic conveyor systems. Vertical Lift SPF1S: Transport direction in “S” form. Outfeed side always opposite the infeed side. Vertical Lift SPF1C: Transport direction in “C” form. Outfeed side always on the infeed side.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Economic + maintenance friendly articulated arm robot alternative • Flexible plastic case + carton tray stacking heights • Changeover times for gripper and format parts are eliminated due to automatic format changeovers • Unit performance can be expanded through additional stackers • Use of Euro pallets, Duesseldorfer half pallets + industrial pallets Within limited space situations the fully automatic stacking and palletizing unit is the first choice for flexible handling of all market formats. The slimly designed Stacker is economical + mainteance friendly when it comes to stacking plastic cases, meat crates, nestable carton and trays, mixed pallet commissioning or bakery baskets without pallets . Product and format changeovers are software controlled and require no tools. The Stack Palletizer is ideally suited for palletizing pre-stacked containers and the shuttle system allows for collecting different product stacks and creating mixed product pallet loads.

Results for

Plastic tray - Import exportNumber of results

8 ProductsCountries

Company type