- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- picks

Results for

Picks - Import export

TRAPO GMBH

Germany

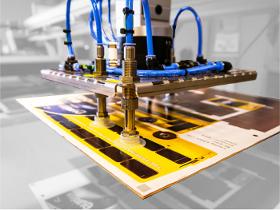

As a supplier of complete systems, TRAPO AG supplies modular High-Performance-Pick & Place-Systems that combine components such as robots, frame units, camera systems and conveyor technology. The modular system can be adapted to different framework conditions and thus covers almost any application. The TRAPO HPPS series forms the heart of the modular picker cell. The high-performance picker line combines maximum performance, individual TRAPO gripper technology and proven know-how, for example in the field of hygiene design.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

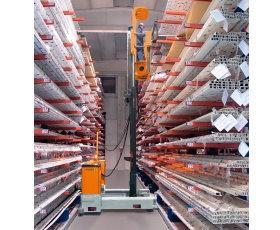

Fully automated storage In the automotive industry, storage in high-bay warehousing and precise, sequential provision are a vital part of the production process. Your advantages using Lödige solutions for efficient storage and order picking Custom-made racking systems Optimum use of space Storage for every sort of component Connection to internal materials handling systems Storage, materials handling and control technology — all from one source Quick and safe storage

Request for a quote

HANS TURCK GMBH & CO. KG

Germany

Pick-to-light systems control and monitor commissioning, configuration and installation processes. For example, the light screen located in front of a picking bin captures the hand of the operator and reports removal back to the control. Then job lights indicate in which bin the operator has to reach next. Pick-to-light solutions are available in various versions, also for direct mounting on picking bins.

Request for a quote

ROLLON GMBH

Germany

Versatile multi-axis system designed for feeding machine stations. The Y axis can be realized with a rack and pinion driving system for multiple independent carriages or with a short belt system for connected Z axes. The motion systems can be designed with recirculating ball guides or with bearings depending on loads, dynamics, and different environments. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

SAMSYS GMBH

Germany

The mobile robot ER Work from EasyRobotics is a compact robot station which can be used for handling work or CNC assembly. The ER Work is most often used in combination with the ProFeeder Compact. Here the ProFeeder Compact serves as a kind of parts store. In this case the ER Work loads and unloads the machine. Of course, the ER Work can also do its work alone in front of a CNC machine.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Control of thread density / course density / basis weight The Famacont PMC determines the thread density by means of a non-contacting, optoelectronic or imaging process. With the optoelectronic process individual threads or courses pass the sensor and are projected onto the photocell using a precision optical lens. The resulting frequency is proportional to the thread count. A high-resolution camera is used with the imaging process. The image is analysed with using suitable software (FFT analysis). Both, the thread count in weft and warp direction can be determined here with maximum precision.

Request for a quote

SAMSYS GMBH

Germany

The pick-and-place robot ProFeeder from EasyRobotics consists of a basic module and two carriages, which guarantee a big range of workpiece pick-up options. A cost-effective application that sets new standards in precision machining when combined with a robot from Universal Robots. Equipped with special software and the help of UR+ Caps, set-up times as well as processing times can be greatly reduced. In addition, employees can concentrate more on more important activities and increase productivity.

Request for a quote

SAMSYS GMBH

Germany

The ProFeeder Compact from EasyRobotics is a robust robotic cell with compact dimensions that can be easily moved in your production. The ProFeeder Compact is placed separately in front of the machine to be operated. Then an ER Work or an ER Pedestal is positioned in front of the machine. The robot is located on the ER Work / ER Pedestal. The robot now takes workpieces from the ProFeeder Compact and loads and unloads the machine. It then loads the workpieces back into the ProFeeder Compact. This results in advantages for you, such as more space in your production, quick adaptability for different workpieces and a mobile robot cell. Thanks to the simple design of the drawers of the ProFeeder Compact, workpieces of various sizes and lengths can be processed without major changeover work.

Request for a quote

SAMSYS GMBH

Germany

The automatic drawer system ProFeeder X from EasyRobotics with its up to 10 drawers is perfectly suited for productions from small to large series. It shines not only because of its performance thanks to the included software, but also because of its changeover times. The software, which has been specially created for the ProFeeder X, makes it easier to write the robot programs in the palletizing area. This reduces tiresome programming times and increases productivity at the same time.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our production facilities are fully up to date. Thanks to the adjustable design of our lines, we can easily implement special solutions. High-performance placement machines by ASM with short setup times and high flexibility form the backbone of our automated SMD placement systems. Our services also include assembly of THR components (pin-in-paste technology). Extensive monitoring systems and built-in cameras ensure high precision in the placement process.

Request for a quote

TRAPO GMBH

Germany

4- or 6-axis jointed-arm robots of various well-known brands are acting highly flexible. The high-speed systems palletize, sort, load and commission fast and high-precision single pieces, rows, partial layers or complete layers. - Low space requirement - Flexible use for various applications - Product and industry independent: Mature gripper technologies transport a wide variety of goods - Suitable for different packages and load carriers - Set on rails, the jointed-arm robot moves to different palletizing positions - Application-oriented, flexible combination of the optimally complementary technical properties of high-speed palletisers and robots

Request for a quote

EUROLASER GMBH

Germany

Optimise your production process by automating the supply of your laser system. With our flexibly configurable and scalable robot systems, your jobs will be done quickly and accurately. Fully automated process operation The table already loaded with the new material will be released through a digital signal. Once the working process on the second table is completed, the change will start fully automatically. The new material is cut automatically while the robot will unload the finished work pieces, parallel to the cutting process and without downtimes.

Request for a quote

HUBTEX MASCHINENBAU GMBH & CO. KG

Germany

The function of the model MK is the warehousing and order picking of doors and frames in pallet racks. This order picking platform is a classic Electric Multidirectional Sideloader for the warehousing of complete packs and, with man up cabin, for picking individual customer orders. The model MK has a fixed mast. A lifting device for lifting and lowering the load to an ergonomic working height as well as telescopic forks for placing whole door packs into stock and removing them from stock are optionally available. Product can be taken out of the rack from both sides of the rack quickly & easily. Operation and use: One-man or two-man operation Warehousing and order picking of doors and frames in pallet racks. Load capacity range: 1,500 to 4,000 kg Lifting height: up to 75000 mm Aisle width: Load depth plus 400 mm (if guided: with 100 mm safety clearance per side) Order picking rate: Based on 7 picks per pick stop 150 picks/day 750 picks/week 3.000 picks, sheets/month

Request for a quote

HUBTEX MASCHINENBAU GMBH & CO. KG

Germany

Model EZK pickers are pure order picking platforms. Whether as twin mast or scissor lift version - order picking of up to 8 m long profiles or sheet stock which is between 600 mm and 2100 mm deep can be performed with these systems. The goods can be easily picked from either side of the rack aisle. The twin mast version distinguishes itself by its especially low platform height. The platform height of the scissor lift version is greater. The advantage of the scissor lift version is its shorten overall chassis length. A load shifting device is optionally available for both models to facilitate the removal of the order-picked goods by a separate fork-lift truck. Operation and use: One-man or two-man Load bearing classes: 2,000 to 10,000 kg Lifting height: up to 10,000 mm Aisle width: at least 2700 mm / maximum aisle width conditional upon load depth. (if guided: 150 mm safety clearance per side) Order picking rate: based on 3 sheets per pick stop 450 sheets/day 2,250 sheets/week 9,000 sheets/month

Request for a quote

HUBTEX MASCHINENBAU GMBH & CO. KG

Germany

Model KP can be used as classic Electric Multidirectional Sideloader for the warehousing of complete packs and, with the platform installed, for order picking of individual customer orders. During the order picking operation, all functions are controlled from the platform. Fork-lift truck and platform form a unit. This order picker can be used for the one-sided rack operation in narrow aisles and moreover for the two-sided rack operation in unguided aisles. (End picking of window profile for example) The order-picked goods are safely removed by a separate fork-lift truck simply by lifting safety barrier Operation and use: One-man or two-man operation for up to 6 m long lightweight profiles and sheet stock which is between 600 and 2100 mm deep Load capacity range: 1,500 to 7,000 kg Lifting height: up to 10000 mm Aisle width: One-sided rack operation in narrow aisle: Load depth or cantilever arm length plus 1350 mm (if guided: with 150 mm safety clearance per side) Two-sided rack operation: Load depth plus 1000 mm (if unguided: 500 mm safety clearance per side) Order picking rate: based on 10 – 15 sheets per pick stop 350 – 400 sheets/day ca. 1,850 sheets/week ca. 7,400 sheets/month In this example you need about 3 hours per day to restock the warehouse.

Request for a quote

HUBTEX MASCHINENBAU GMBH & CO. KG

Germany

The model MU-SO one-man and two-man order picking system is used for order picking of long loads. It is especially designed for aluminium, plastic or steel profiles and for order picking in narrow aisles. With this order picking truck, product can be taken out of the rack from one side of the aisle quickly & safely. The model is available as classic Electric Multidirectional Sideloader for placing complete packs in storage, and as version with man rising cabin for picking applications with regard to individual customer orders. Operation and use: One-man or two-man operation, also for heavy profiles Order picking of up to 12 m long loads Load capacity range: up to 5.000 kg Lifting height: up to 9000 mm Aisle width: Load depth or cantilever arm length plus 962 mm (if guided: with 100 mm safety clearance per side)

Request for a quote

HUBTEX MASCHINENBAU GMBH & CO. KG

Germany

The model MU-OP one-man order picking system is used for order picking of long loads. It is especially designed for aluminium, plastic or steel profiles and for narrow aisle operation. With this order picking truck, product can be taken out of the rack from one side of the aisle quickly & safely. The model is available as classic a Electric Multidirectional Sideloader for placing complete packs in storage, and as version with man rising cabin for picking applications with regard to individual customer orders. Operation and use: One-man operation for lightweight profiles Order picking of up to 6 m long loads Load capacity range: 1,000 to 2,500 kg Lifting height: up to 7000 mm Aisle width: Load depth or cantilever arm length plus 1230 mm (if guided: with 100 mm safety clearance per side)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IAI INDUSTRIEROBOTER GMBH

Germany

SCARA robots are often used for the fast removal and movement of workpieces, smaller assembly applications such as screwing in screws, and for the precise dosing of liquids, adhesives and sealants. IAI offers a wide range of models, from the low-cost entry model IXP to the latest IXA high-performance SCARA robot.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The "Metzner RPA 60-LT" is a powerful robot press automation with an outstanding storage system for the highest demands in the handling of pressed parts made of hard metal and metal powder. With a storage capacity of up to 60 sintering plates, the it offers outstanding possibilities for the production of sintered parts of all types. All sintering plates are fed to the machine via four transport trolleys with 15 plates each. The intelligent handling system of the "RPA 60-LT" ensures uninterrupted loading of the pressed parts. While the first sintering plate is filled by a linear robot with multifunctional gripper, the handling system provides a second empty plate. As soon as the first plate is filled, the loading of the second one starts. Meanwhile, the handling system returns the loaded sintering plate to the transport carriage. The automation thus works according to the Kanban principle, which ensures that the press can be operated continuously even during the workpiece carrier change

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The "Metzner RPA 10-SL" is a powerful and flexible press automation system for handling indexable inserts and small ceramic parts for medium to large batch sizes. It has an integrated magazine system for up to ten sintering inserts. Empty sintering inserts are automatically removed from the magazine, loaded and then returned as required. In this way, the powder press automation works independently over a longer period of time without loading and unloading processes leading to a press stop. With its integrated 4-axis SCARA robot, the machine achieves very high system speeds of up to 30 stroke/min. The "RPA 10-SL" is operated conveniently via the integrated control or via the mobile operator terminal. At the push of a button, loaded sintering plates are removed and new ones received. Defined operating data are transferred to the press control via an interface.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

RS 1XL For Everyone Who Wants to Assemble Larger Circuit Boards The RS 1XL combines the advantages of the RS 1 and RS 1R with the possibility of assembling printed circuit boards up to 560 mm wide (for comparison RS 1 / RS 1R max. Width 370 mm). With slightly larger dimensions than a RS 1, the RS 1XL offers the same advantages fast assembly of the smallest chips (0201 metric) to large components of 50 x 150 mm or 74 mm edge length for square components. The machine combines the properties of a chip shooter with a mounter for large components. There is no need to purchase a special machine type.duct 3 description and specification ...

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Compact High Speed Mounter JUKI’s JX 350 offers high flexibility and quality presented in a compact design while maintaining an attractive low price. This model handles long printed circuit boards up to 1.50 metre and is expecially suitable for cost efficient LED assemblage. On top of that the incorporated laser technology enables a highly accurate placement of diffusion lenses due to the recognition technology which identifies the main orientation of the lens.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Speed Mounter JUKI’s FX 3 stands for ultra fast, precise placement of micro components on printed circuit boards. It is the perfect solution for companies wanting to process large volumes. Among the strong points of the FX 3 are short retooling times thanks to quick change feeder banks as well as minimal maintenance. The user friendly touchscreen interface plus the powerful optimisation software provide additional ease of use.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

High Speed Compact Modular Mounter JUKI’s RX 6 is the perfect solution for companies in need of a wide variety of components and large printed circuit boards as well as having to depend on quick product changes while maintaining high quality. The high speed compact modular mounter is suitable both for small and large volumes. Due to the compact design of the machine featuring a width of only 1.25 metre the RX 6 displays a smart solution in the case of production floor space being an expense factor.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Next Generation Smart Fast Modular Mounter The consistent further development of the tried and tested technologies from the RS 1 opens up new, outstanding possibilities Even faster assembly of smallest chips (0201 metric) up to large components of 50 x 150 mm or 74 mm edge length for square components. The base frame of the RS 1R has been completely redesigned for this purpose. The unique Takumi head covers even more different component heights and thus achieves a decisive speed advantage. The 360 ° visual component recognition allows the secure detection of user specific polarity marks. Thanks to the RFID integration in the nozzles, these can be traced back completely together with the components and boards. The machine combines the features of a chip shooter with a mounter for large components. The purchase of each special machine type for it eliminates as well as a change of the placement head.

Request for a quote

JUKI AUTOMATION SYSTEMS GMBH

Germany

Latest Generation of Ultra High Speed Mounter The RX 7R is the first choice when it comes to the high speed assembly of a large number of printed circuit boards with smaller and smallest components. The successful concept of the RX 7 has been further developed into the RX 7R. The new placement head P16S offers increased accuracy and a longer service life. The compact machine design with a width of one meter has been retained and continues to offer maximum productivity in the smallest of spaces.

Request for a quote

NORIS GROUP GMBH

Germany

Mechanically connected, screw-in speed encoder with square wave output signal. Cost-effective speed sensor with square wave output signal. Can be mounted directly instead of using a flexible shaft. Can be loaded with 50 mA SINK and 20 mA LOAD. High EMC protection for harsh electrical environments. For harsh environments up to IP67.

Request for a quote

NORIS GROUP GMBH

Germany

Mechanically connected, screw-in speed encoder with square wave output signal. Cost-effective speed sensor with square wave output signal. Can be mounted directly instead of using a flexible shaft. Can be loaded with 50 mA SINK and 20 mA LOAD. High EMC protection for harsh electrical environments. For harsh environments up to IP67.

Request for a quoteResults for

Picks - Import exportNumber of results

38 ProductsCountries

Company type

Category

- Moulding, rubber - machinery (6)

- Robotics (5)

- Sensors (3)

- Automation - systems and equipment (2)

- Goods handling systems, continuous (2)

- Mechanical engineering - custom work (2)

- Electrical & Electronic Components (1)

- Internal transport systems (1)

- Lifting - vehicles (1)

- Lifting equipment - accessories (1)

- Sack trolleys (1)

- Textiles - Machines & Equipment (1)

- Transport, indoor - rolling equipment (1)