- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pharmaceutical packaging

Results for

Pharmaceutical packaging - Import export

GAPLAST GMBH

Germany

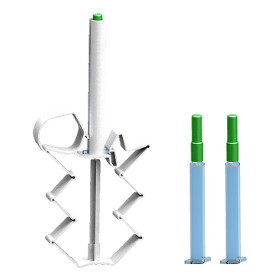

LIQUID Sub-cutaneous Use The prefilled syringe is mounted into the reusable activation device. After removal of the tip cap, the ModularInject is placed to the injection point. By activating the device, the skin is penetrated and the drug substance is injected. After the injection is finished, the syringe is discharged and can be disposed as usual. The activation device is ready for the following administration. ModularInject Monodose Injection Unique and smart solution to close the gap between manually applied prefilled syringes and complex auto-injectors. Single Use: Prefilled syringe with tip cap Multiple Use: One-piece activation device with an integrated plunger, automatic penetration, traveller and needle security functionality System Benefits (B2B) Applied/used either with a standard prefilled syringe in accordance to ISO 11040-4 or alternatively with an own developed packaging optimized prefilled syringe Free set combination of different dosages or different drugs...

Request for a quote

GAPLAST GMBH

Germany

SOLID Oral Container Closure Systems The preliminary task of each packaging system is to store and protect the content. But at the same time it is also inevitable to match the ease of use when opening and closing the container. Whilst fitting to different designs of container openings, like • snap on (Ø 19,85 mm – 54,50 mm) • screw or different container materials, like • plastic • aluminium • glass the following closure features are available solely or in combination: • tamper-evident • with integrated desiccant • for tablet storage • with distance holder: by an additional bellow or by an integrated spiral • childproof (ISO 8317 & CFR §1700.20) by integrated, self-resetting push-pull slider Senior friendly desiccant stopper with pull tab Unfortunately, a gain in ages usually goes along with a loss in power. Therefore, the target is to engineer an easy to use packaging which also fulfils pharmaceutical requirements. System Benefits (B2B) • Compatible to standard and already in.

Request for a quote

GAPLAST GMBH

Germany

LIQUID, SEMISOLID Nasal, Ophthalmic, Topical, Oral, Auricular Use The prefilled cartridge is mounted via bayonette into the reusable activation device. After twisting off the tamper evident tip, the modular dose is placed to the intended area of application and the activation device is squeezed to apply the product. Monodose with spray or drip pattern or injection (ModularFamily) Monodose with spray, drip or line pattern ModularUnitDose The evolution of a monodose results in the patented new development of the ModularUnitDose with a spray, drip or line pattern. To achieve this functionality, the modular dose consists of the following components: Single Use: Prefilled cartridge with a tamper evident twist off tip Tip design according to spray, drip or line pattern Moveable stopper Multiple Use: One-piece activation device with an integrated piston System Benefits (B2B) Reliable and correct dosage of drug delivery Combination of different dosages possible, just by varying the...

Request for a quote

GAPLAST GMBH

Germany

LIQUID, SEMISOLID Nasal, Ophthalmic, Topical, Oral Use The AirlessMotion products can be combined with numerous dispensing units for: horizontical or vertical outlets spray, dropper or lotion pumps snap, crimp or screw neck design push button or trigger activation Airless container for pump & squeeze application AirlessMotion Reaching the utmost level of integrity sterility without preservative agents also during multiple use of a dosing system, requires highly engineered packaging. First of all, the container itself has to match these needs. A multilayer bottle has been evolved into a hybrid packaging consisting of a rigid bottle layer and a flexible, contracting integrated bag. The resulting system allows an airless pump not to vent the container with contaminated air during multiple applications, also if there are longer pauses in-between. Numerous patents are protecting the IP of product, function and process. Benefits of the system (B2B) Formula without preservative...

Request for a quote

GAPLAST GMBH

Germany

LIQUID Sub-cutaneous Atmospheric squeeze dropper systems Multidose Standardized application system to squeeze drops in a multiple use. The 100% control of the dropper guarantees the functionality. Furthermore, the tamper evident screw cap ensures the integrity of the product throughout the shelf life. Atmospheric container for pump application Multidose Although products seem to be widely established and standardized, there is always a chance for improvement. For example with the unique and patented cross section bottom design of the 10 ml, 20 ml and 30 ml HDPE bottle, suitable for 20 mm snap on pumps. System Benefits (B2B) Dip tube no longer touches the bottle during assembly of the pump Avoids line stops during pump assembly Consumer Convenience (B2C) Regularity of the residual volume NNo risk of malfunction due to bended dip tubes

Request for a quote

WHITESTEEL GMBH

Germany

- Compact design - Made up to the ISO, FDA and EU, GMP and cGMP international standards - Can handle multiple cups shapes and sizes - SCADA system included - Touch screen included - Capacity is adjustable up to your needs - Can be used For all liquid substance including alcohol, sanitizers, hand gel, and more

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The compact 3VPHD8 Pharma Dispenser enables precise and reliable dosing of a wide variety of materials. Thanks to the special rotor-stator-geometry, no valve is required to prevent the medium from flowing out independently. Alternating opening chambers ensures gentle product transport and pulsation-free output. The VPHD series was specially developed for applications in the pharmaceutical, biotechnology, medical and food industries. Your advantages: - Interior with optimised dead space - Design according to EHEDG guidelines - FDA-compliant design/development - hygienic and pharmaceutical design - Works certificate 3.1 (DIN EN 10204) - all surfaces for pharmaceutical applications Ra ≤ 0.8 μm - retraction option (no dripping or thread pulling) - absolutely linear relationship between rotor speed and spread rate - long service life due to media-specific component selection

Request for a quote

RHEIN-PLAST GMBH

Germany

costumer tailored high quality bags and sacks: # regular confirmation of our GMP at customer audits # Close cooperation between our QS and well-known raw material suppliers # corresponding approvals (Pharm. Eur., DMF, USP) References: Sanofi, GSK, BAYER, BOEHRINGER, GREINER, ABBVIE, ...

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: Jetting hose with antimicrobial protection TRELLJET 681 ANTIMICROBIAL PROTECTION is specially designed for professional and industrial high pressure cleaning and is suitable for all environments where bacteria are concerned: cleaning companies, food industries, pharmaceutics, packaging/bottling, health care institutions, schools, etc. Suitable for mobile pressure washers, fixed installations and reel mounted applications. The hose is crush resistant, has a non-staining smooth cover, is resistant to oil, detergents, wear and weather.

Request for a quote

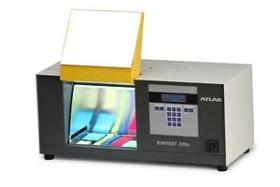

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST CPS+ is the small entry model. CPS+ is the most widely used benchtop xenon instrument in the world. Its compact design, easy handling and proven reliability make it the ideal quality control and R&D screening device for a variety of industries, such as plastics, packaging, pharmaceuticals, cosmetics, and many more. 1x 1500 W air-cooled Xenon Lamps 560 cm 2 exposure area Measurement and control of Irradiance in the wavelength range 300-800 nm / Lux; or 300-400 nm / 340 nm Measurement and control of Black Standard Temperature (BST) Display of Chamber Temperature Display of Test Values and Diagnostic Messages Parameter Check Two pre-programmed test methods Storage for 6 user-defined test methods Multilingual User Interface Benchtop design 90 x 35 x 35 cm Static, horizontal exposure area for flat or 3D specimen Fan-controlled BST from 45-100 °C (without chiller unit SunCool) Non-aging reflector and filter system, consistent of selectively reflecting mirrors and a coated quartz Switch-off choices Radiant Exposure or Test Time Base Filter as carrier for additional optical filters Data output via serial interface RS232 Internally integrated Memory Card for Software Updates Light Monitor 300-400nm Light Monitor 300-800nm Humidity Sensor for measuring relative humidity during testing

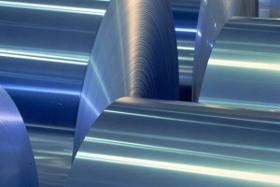

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis aluminum converter foil is a part of the light- or thin-gauge product group, ideally between 5 and 70 μm. They form flexible laminates with supporting materials like polymers or paper and additional lacquering and coating. Novelis is a preferred source of converter foil for global players in the flexible aluminum packaging industry, where it is then subjected to further processing, including laminating, extrusion, lacquering and printing, embossing and cutting. The versatility and flexibility of the products enable our customers to create a diverse range of packaging solutions, finding end applications across diverse industries such as food – including butter packaging and cheese packaging – pharmaceuticals, wraps, bottle capsules, laminated tubes, pouches and more.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The products are manually placed on the conveyor belt, printed from above and collected at the end of the system. The portable system is equipped with a Wolke m610 Touch thermal inkjet system. An upgrade to a manual serialisation system with b+b Linemanager and Full Vision System is optionally available. The conveyor belt is driven by a powerful stepper motor with constant speed. The conveyor belts are provided with crossbars at regular intervals to achieve constant product guidance and thus a consistent print result. The distance between the two toothed belt conveyors can be easily adjusted in order to process different product widths. For processing slightly slanted products, the positions of the crossbars can also be adjusted to each other.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This workstation enables the manual serialisation of drug packages and their aggregation into shipping cases. For this purpose, each individual box is first printed with order-related serialisation data by a thermal inkjet printing system as it passes by and then manually placed in a shipping carton. As soon as it is filled, the downstream thermal transfer label printer creates an individual serialisation label. The correct print data and print quality are permanently monitored by a vision system. The operator places the medicine products to be serialized on a reference edge at the infeed. As soon as the thermal inkjet printer has printed the serialisation data, the integrated vision system checks that the data is correct. If an error is detected (e.g. insufficient grading), the product stops at a certain position marked by red LEDs. The removal of the rejected product must be confirmed by pressing a button on the HMI.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The STS-B was developed for the simple aggregation of pharmaceutical packs into a bundle. For this purpose, the barcodes of serialized products are captured from below by the vision system through a scratch-resistant glass plate. The distance between camera and barcode therefore always remains the same. The maximum working surface is 420 mm (W) x 300 mm (D). The detected serial numbers are marked in green so that they are easy for the operators to understand. Depending on the configuration, the system can compare the recorded serial numbers with the default values of the L3 installation. Particular attention was paid to user guidance (workflow) in order to achieve maximum process reliability. In order to completely fill the carton layer(s) or spaces, barcodes that cannot be placed with the barcode facing upwards due to their orientation can be manually added in each layer by the integrated handheld scanner to complete the respective layer or carton.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The LSS-PV model was developed to serialize small product batches cost-effectively and according to the requirements of country-specific FMD guidelines. The products are fed manually. A transport system with product carriers guarantees a precise and continuously accurate alignment of the products. After the printing process performed by a thermal inkjet printing system (TIJ), the print data is inspected. If the inspection result is positive, the products are either collected on the collection table at the outfeed of the system or glide over an optionally available transfer plate into an outer shipping case. Defective products are reliably separated from the GOOD products by the product reject station. This process is verified twice in the PLC.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

s with the MS-PV-AG model, the products are fed manually by the operator. Product carriers and adjustable guide rails ensure a stable product transport. As soon as the thermal inkjet printer has printed the serialisation data, the integrated vision system checks that the data is correct. If an error is detected (e.g. insufficient grading), the product is removed from the process and fed to a lockable collection box. It is not taken into account during the formation of the aggregation pedigree and is ejected and marked in the shift register as soon as the error is detected. As soon as the filling quantity per carton is reached according to the specified packing scheme, the system automatically generates a serialized label for the shipping carton. It is applied manually by the operator and confirmed by a handheld scanner that the aggregation label has been applied.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The MAT model series serves as a mobile terminal for all aspects of aggregation and rework. Aggregation and rework can take place over several levels. The devices are available in the following expansion stages: MAT-C Manual aggregation and rework station (1 level) (boxes – shipping cases) MAT-P Manual aggregation and rework station (1 level) (shipping cases – pallets) MAT-CP Manual aggregation and rework station (2 level) (boxes – shipping cases – pallets)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This powerful HSF friction feeder is the optimal solution when empty folding boxes have to be marked with variable data offline from the production line. The modular design of the system enables an easy integration of the desired marking technology. The HSF separates the folding boxes from the stack in the infeed magazine. The cartons are guided to the printing station by two parallel running belt conveyors. Print information could be e.g. serialisation data in the form of bar codes or data matrix codes and text. Depending on requirements, thermal inkjet, laser coders or label print- and apply systems can be used (also in combination). The printed data is inspected and verified by an integrated vision system. The b+b Linemanager recognized all 21CFR Part 11 data for each serial number and is able to report this back to the Siteserver system (e.g. b+b Siteserver).

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

To serialize vials and other cylindrical products, we rely on the proven quality and reliability of our labelers. In order to achieve the best possible grading of the serialisation barcodes, we integrate thermal transfer printer or marking laser units directly on the label applicator. The vision system immediately inspects the print data after the printing process. If the inspection shows a negative result, we optionally offer a label reject station which automatically removes the label from the process and therefore does not waste a „good product“. Both the vision system and the print engine are fully integrated in the touch panel HMI. Shift registers in the label applicator as well as in the complete system enable product and label tracking through the complete system.

Request for a quote

STI GROUP / STI - GUSTAV STABERNACK GMBH

Germany

Over ten percent of medicines worldwide are counterfeit, according to a study by the US Food and Drug Administration (FDA). As a specialist in pharmaceutical packaging, the STI Group embraced the challenge to design a pharmaceutical packaging that patients, pharmacists and hospitals can rely on and that ensures that the product in their hands is an original product. The pharmaceutical packaging protects people against counterfeit medicines and the pharmaceutical industry against high financial losses.

Request for a quote

HEXPOL TPE GMBH

Germany

Our coloured Mediprene compounds are made from medical grade raw materials only, thereby representing a natural expansion of our Medical TPE product range. The colour masterbatch supplier has been selected with care, ensuring that not only the pigments and carriers are compliant with USP Class VI or corresponding parts of ISO 10993 but also that the masterbatches are manufactured under rigorous controls with regard to traceability, consistency and change control thereby fitting the Mediprene concept at our ISO 13485 accredited facilities. In medical devices and pharmaceutical packaging colour is often used functionally to differentiate products and provide an easy method of identification. The vibrant colours achievable with coloured Mediprene compounds also give brand owners a means of adding value to their products and creating visual appeal. A fully colour compounded TPE gives a perfectly dispersed, consistent colour with a correct and reproducible addition level. Mediprene colou

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

Package Leak Detection system using a water-based bubble test. LEAK-MASTER® EASY allows the detection even of the smallest of leaks. After the package is placed into the chamber filled with water, the head space above the water level is evacuated using a venturi vacuum (compressed-air) system. This causes the package immersed in the water to inflate, allowing any leaks and their location to be identified by a stream of bubbles. Benefits: economical and uncomplicated visual inspection allows localisation of the leak for all flexible and rigid kinds of packaging (food-, pharmaceutical-, industrial- and other packaging) short testing period (< 30 sec.) easy-to-use intuitive operation – no special skills required easy installation and start-up no trace gas required in package can also be used for altitude simulation optionally also for vacuum packaging, set order-No. 956992700 no calibration required various chamber sizes avail

Request for a quote

STI GROUP / STI - GUSTAV STABERNACK GMBH

Germany

The packaging design of the medicine box makes it easy for the elderly to take their daily medicine. The packaging solution for pharmaceutical products has a separate compartment for removal of the tablet in the front in which the broken blister is put. A curved inner flap in this compartment ensures that the blister is slightly wedged in. This inner flap also has anti-slip varnish.

Request for a quote

OPTIMA PHARMA GMBH

Germany

All commercially available ready-to-use syringes (glass and plastic) All commercially available safety devices Gently objective handling Simple operation Continuously working Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Aseptic fields of application Gently objective handling Compensating for height tolerance Simple operation Intermittent operation or continuously working Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

100% In-Process-Control (100% IPC) ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

Gently objective handling Simple operation Continuously working Processability of all commercial closures Small amount of format parts Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

ATEX model optional Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Simple operation Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

OPTIMA PHARMA GMBH

Germany

ATEX model optional Gently objective handling Dosing system: Mass flow with CIP/ SIP optional Dosing system: Rotary piston system, peristaltic pump system, time/pressure dosing system with or without CIP / SIP optional Optima with headquarters in Schwaebisch Hall, Germany, teams with its subsidiaries to design and build packaging equipment for pharmaceutical, consumer, nonwoven and life science products – from single standard machines to complete complex turnkey systems. Whether custom solutions or modular standard units, functions are consistently tailored to the specific needs of the customers and their industries. Optima is the worldwide leader in packaging technologies for many fields. Founded in 1922, the family owned and operated business is in its third generation and employs a workforce of 2,050 at its sites in Germany and 13 locations abroad. An export share of more than 80% is indicative of the company’s international standing.

Results for

Pharmaceutical packaging - Import exportNumber of results

60 ProductsCountries

Company type

Category

- Pharmaceutical industry - machinery and equipment (27)

- Chemicals and pharmaceuticals - packaging machinery (11)

- Chemical and pharmaceutical industry - machinery and equipment (6)

- Packing and packaging - machinery and equipment (4)

- Aluminium foil for packing (1)

- Bottling and filling - machinery and equipment (1)

- Films and sheets, plastic (1)

- Leak detectors (1)

- Packaging (1)

- Printing (1)