- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- peripherals

Results for

Peripherals - Import export

N&H TECHNOLOGY GMBH

Germany

We are your reliable partner for the realisation of your products - from the initial idea to series production and beyond. Our goal is to offer you a comprehensive full service and to manufacture your products economically and in the highest quality. We support you in the consultative development of your early concepts and prepare an initial cost estimate in the concept phase. In addition, we accompany you during series and mass production with our long-standing manufacturing partners in the Far East and ensure reliable logistical handling.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

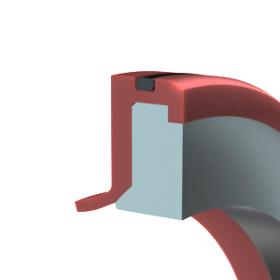

Motor shafts. Gear and frive unit shafts. Fan shafts. Clamping tools. Applications at high speed and lo pressure.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Full power in any position The universal machines from BEHRINGER can handle any job that is needed. Perfect to slicing through sectional steel as well as solids in metal and comparable plastics at almost any optional angle. With precise cuts, individually adjustable for bidirectional mitre cuts between 90° and 45°, and optionally even for acute angles of 30°. Semi-automatic variants In the BEHRINGER semi-automatic models, the material is positioned by eye, for instance with the aid of a linelaser. This procedure is recommended for frequently changing cut-off length and when the sections are marked on the material already. Automation Where larger cut-off lengths are required, we recommend the use of a measurement device for precise positioning of the material. Used in conjunction with infeed and outfeed peripheral devices such as roller conveyors and transverse transport devices, the degree of automation can be increased to achieve added streamlining effects.

Request for a quote

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser supplies high-precision mechanical presses for sheet metal forming. The decades of experience and the technical execution of the stamping and forming machines guarantee exceptional precision, high productivity and reliability as well as a significant reduction in operating costs. However, a forming line consists not only of the press but of a number of ancillary equipment and auxiliary units, which only result in a functioning system as a whole. We have more than 70 years experience in the integration of press and peripherals. Our experts know exactly the mutual dependencies and requirements of the individual sub-systems. Profitability and productivity are the result of an optimally coordinated system. We are happy to advise you on the planning of your forming plant. However, a forming line consists not only of the press but of a number of ancillary equipment and auxiliary units, which only result in a functioning system as a whole. We have more than 70 years...

Request for a quote

FRIMO GROUP GMBH

Germany

The right mix From basic to high-tech, FRIMO offers peripheral equipment for all PU processing technologies.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARRAG GMBH

Germany

The RVU grinding machines set new standards in highprecision machining and are especially suitable for high precision grinding applications in the bearing and aerospace industries. The range can be equipped with up to four watercooled grinding spindles which can achieve a performance of 45 kW at 18,000 rev/min. (according to the type of grinding wheel selected) The RVU facilitates a complete machining processing without interruption as optional dressing units, grinding wheel changers and workpiece measurement are available. Additional options for hard metal machining boring and workpiece measurement increase the possible applications of the machine series considerably.

Request for a quote

STARRAG GMBH

Germany

With the FOGS NEO series, Droop+Rein has developed a powerful machine concept for complex machining. The range of services covers processes from machining standard geometries and prefinishing contours to final finishing. For dynamic machining with the highest feed rates, the concept caters for the movement and acceleration of constant masses, regardless of workpiece size and weight. Dynamic and flexible With its new, highly flexible and fast Caxis (±400°), the Droop+Rein FOGS NEO highspeed machining centre is ideal for the complete multifunctional machining of very large workpieces. Of course, the series also features automatic pallet or tool change, tool diameter and length measurement and automatic billing of contour deviations. Thanks to a variety of components and peripheral devices from their modular system, Droop+Rein can create an efficient and processoriented overall system that is tailored to the customer.

Request for a quote

H. TIMM ELEKTRONIK GMBH

Germany

APPLICATION - To transfer data between the installed peripheral devices located in the hazardous areas (card readers, input terminals, EUS-2 Overfill Prevention Controller) and the host control system e.g. terminal administration and automatization Software - To build-up an explosion-proof intrinsically safe data bus and realization of the connected field devices BENEFITS - Project specific configuration possible by modular design in the subrack - The KCP Processor Module incl. the interface to the host system and the KCI Interface Module for connection of field devices can be linked to another - A processor group with several interface boards can be operated up to 32 slaves - The interface module enables a safe electrical isolation between the bus circuits and the processor module

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

With the DHC Premium solid carbide end mills, LMT Tools significantly increased the performance of the low-vibration premium tools: 25 % added machining volume is the result of different helix angles in connection with newly developed, stable front cutting edges and peripheral teeth. Additionally, the new cutting material LCPK30M including an innovative PVD high-performance coating contributes to an improved tool life and a safe chip removal. A special performance feature of the DHC Premium end mill (Different Helix Cutter) by LMT Fette consists in its multifunctionality: it allows the user to rough and finish with the same tool. It can also produce narrow projections and up to 2xd-deep slots in steel and cast materials with exceptional surface quality. Advantages: - Increase of the machining volume by 25 % - Increased process reliability due to stable cutting edges - Multifunctional – roughing and finishing with the same tool

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

In the plastics compounding and manufacturing process there are many powders (all with different flow properties) which require handling. For the vacuum conveying of both free-flowing and non-free-flowing powders, motan has a solution. The METRO P series of hopper loaders are available in two versions and guarantee reliable and dust-free conveying. The METRO PC system loaders are designed to be integrated into centralised motan conveying systems. The METRO PB single loaders are designed to be used as a “stand-alone” solution. From the material source right through to the point of processing, motan offers the ideal solution for your powder handling requirements.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

With the METRO G/F/R material loaders, large quantities of granulate, dusty regrind and flakes can be conveyed automatically to the hopper of a processing machine, drying bin or day bin. Filters with sophisticated cleaning technology and large outlet flaps guarantee trouble-free operation. Via the hinged lid, free from vacuum and material hoses, the loaders can be quickly and easily cleaned during material changes.

Request for a quoteResults for

Peripherals - Import exportNumber of results

12 ProductsCountries

Company type