- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- parts transporter

Results for

Parts transporter - Import export

GSW SCHWABE AG

Germany

tried and trusted a thousand times in practice the low price permits the economic use in individual shift operation and with rarely used tools can be directly mounted to each tool, no setup costs

Request for a quote

GSW SCHWABE AG

Germany

For removing of stamping scrap the GSW Linear Parts Transporters are a much more durable solution over belt conveyors. With compact design, eight different sizes and a strong performance up to 100kg peak load they set a worldwide standard. However, for fast removal of good parts and some scraps, belt conveyors can offer a most suitable solution – especially if the parts are delicate and would suffer from bumping and dirt. That is why for such applications we do offer conveyors too.

Request for a quote

GSW SCHWABE AG

Germany

Instead of mounting one or more Transporters to each die, the PSKS features one unit only – mounted directly to the face of the bolster. A heightadjustable mounting bracket allows flexible usage with multiple tools and dies. The only extra thing needed will be scrap trays in different sizes On the left and right end of the system, heightadjustable brackets with linear bearings support a crossmounted aluminum profile. The profile is fastened with standardized clamping brackets and will transfer the motion over the whole width Numerous trays can be mounted. Two rugged nylon Ushape clamps are permanently fastened to each of the trays. The fasteners are designed to slide and fit snug onto the aluminum profile so that exchanging of trays is just a matter of seconds. The length and width of the tray is determined by the size of the die slot.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Corrosion protection of metal semi-finished products and spare parts during transportation and storage Temporary storage of forms, machines and tools in production and maintenance Advantages and benefits Environmentally friendly VOC-free product on a water base Workplace-friendly and not detrimental to health, since emissions (vapours) from volatile organic compounds do not arise during application Setting of the layer thickness for optimal corrosion protection through dilution with water possible In case of mass coating, pre-heating of the parts to accelerate drying possible Dry wax film fast to handling Can be removed easily with warm water and water-based cleaners, such as OKS 2650 Good adhesion on metal surfaces Neutral with respect to most plastics and paints

Request for a quote

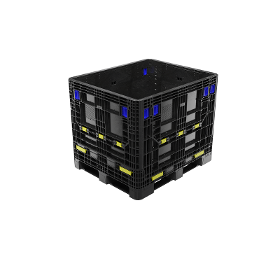

ORBIS EUROPE

Germany

ORBIS reusable bulk containers are designed to protect and transport heavy parts in automotive and industrial applications. Engineered for rugged applications, the plastic bulk containers are extremely robust and offer comprehensive product protection over a long service life. The 1200 x 1000 plastic bulk containers are available in multiple heights for increased packing density. The collapsible design with a return ratio of up to 1 : 3 reduces the shipping of air during return transport to a minimum. Key features: - manufactured from recycled material - multiple heights, access door and bottom configurations - durable all-plastic design - improved workplace safety - easy, on-site repair and part replacement - 100% recyclable

Request for a quote

SAMSYS GMBH

Germany

Unloading machine Multi-3000 remove The Multi-3000 remove is an electro-pneumatically controlled automatic unloading machine. It is the ideal complement to the bar feeder Multi 3000 or the Multi 3000SL. With the Multi 3000 remove it is possible to unload finished parts from sub- or main spindle. The bars are unloaded by unloading tube, pneumatic gripper or also by collet chuck. After unloading, the bars are placed on a prism. From the prism the parts are transported to a deposit. A light barrier monitors the unloading process. The coating of the depositing surfaces enables a particularly gentle handling of the finished parts. Even parts such as piston bars can be unloaded without a scratch. The unloading tube is made of POM material. This also ensures gentle handling. Loading can be done via the main spindle and unloading via the sub spindle. It is also possible to load via the sub spindle and unload via the main spindle. Compatible with almost all types of lathes.

Request for a quote

SPANSET SECUTEX GMBH

Germany

The secutex chain sleeve protects the chain (sandblasting) and the slinger. The protective hose is not well suited for the intensive use and transport of sharpedged parts due to the high surface pressure and the lack of reinforcement. Please note The chain hoses are designed for chains of quality class 8 that conform to standards.

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently grip components of different dimensions, geometries and surface structures opens up completely new possibilities for you. Benefit from ✅ Increased efficiency of your processes ✅ Higher availability of your personnel ✅ Increased production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R15 ✅ Industrial robot applications for components up to 8 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Transporting parts (e.g. large sheet metal parts such as fenders or hoods) ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently handle components of different dimensions, geometries and surface structures opens up completely new possibilities. The small gripping head offers flexible and simple cooperation between man and machine. Benefit from ✅ Increased efficiency of your processes ✅ Increased availability of your personnel ✅ Increase in the production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R40 ✅ Industrial robot applications for components up to 1 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Bin picking applications ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently grip components of different dimensions, geometries and surface structures opens up completely new possibilities. Benefit from ✅ Increased efficiency of your processes ✅ Higher availability of your personnel ✅ Increased production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Employment of personnel ❌ Process complexity Possible applications of the FH-E3020 ✅ Industrial robot applications for components up to 25 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Transporting parts (e.g. large, flat sheet metal parts such as fenders or hoods) ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Tube lifter applications

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently handle components of different dimensions, geometries and surface structures opens up completely new possibilities. The small gripping head offers flexible and simple cooperation between man and machine. Benefit from ✅ Increased efficiency of your processes ✅ Increased availability of your personnel ✅ Increase in the production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R80 ✅ Industrial robot applications for components up to 2 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Bin picking applications ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

TAMPOPRINT GMBH

Germany

A real Plug-and-Play fully automated system which is ready to use anywhere at any time. You only need electricity, gas and air supply, then connect our CLOSURE PRINT COMPACT and production may start. No service technician for commissioning and no special qualified personnel at the customer are necessary. A high-precision, space-saving rotary pad printing fully automated system for small batch sizes. Feeding solution, parts transport for further processing to the point of a complete system solution − everything from one source.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The design of the automatic 7 axis coating machine meets today's market requirements. As such, it can be employed for small and large order batch sizes, it paints the workpiece front and rear faces as well as 3D part geometries without problems. Transport unit for stacking trays/work piece carriers, consisting of:

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

The new FLEXON SafeTopChain was designed with a completely closed upper surface, minimising the risk of crushing in curves or deflections and offering maximum stability for products and workpiece carrier systems. The special surface also enables even the smallest parts to be transported risk-free. Highlights: • Requires the same guides as the normal plastic multiflex chains from the 1700 Series • By using turning disks with a minimum radius of 123.5mm, dynamic friction is replaced by rolling friction; this allows longer conveyors with more curves, as well as vertical/spiral conveyor systems to overcome gradients and providing buffering. • Improved chain geometry enables the use of wider sprockets, thus reducing wear through lower surface pressure when teeth engage.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

EPP MEANS BEING ABLE TO HANDLE HEAVY LOADS EASILY. Expanded polypropylene (EPP) is the ideal basis for a tailored, reusable packaging solution, as the extremely durable material boasts high specific energy absorption. EPP can withstand strain such as shocks and even repeated impacts during transport – the material remains fully functional without any discernible damage and reliably protects the packaged goods. Storopack’s tailored, stackable EPP packaging can be used for solutions with high circulation, such as cargo carriers for the transport of sensitive parts in the automotive industry. An intelligent and, at the same time, simple reusable solution, available in a variety of colors and completely recyclable.

Request for a quote

MK PLAST GMBH & CO. KG

Germany

development of the special bags in close cooperation with the customer. features of foil products are adapted very carefully to the demands by individual developed recipes. Demands of functionality of the special bags are obtained by special solutions at the construction of the machine. ++Contact us, we are glad about new challenges!++ Examples: Bags with special perforation lines, developed for the dosed possibility of taking-out of single items Flap bag with pasted closure, e.g. for the safe transport of component parts (ant-theft device) Bags developed with the focus on emptying without remaining as good as possible Bags / cuttings with high claims to cleanness and/or temperature stabilities Bags / cuttings with high accuracy of measurement

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Parts transporter - Import exportNumber of results

17 ProductsCountries

Company type