- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- paper boards

Results for

Paper boards - Import export

OSMO MEMBRANE SYSTEMS GMBH

Germany

Recovery of flexoprint dye Picture: printing dye (red); ultrafiltrate (orange); nanofiltration permeate (clear) Application: Conditioning and concentration of cardboard printing dyes (flexo print), e.g. paper bag manufacturing, corrugated board manufacturing. Conditioning of the rinse waters by ultrafiltration(UF): Recovery and recycling of dyes, separated by tonality Further conditioning of the permeate by nanofiltration(NF): Recovery of the rinse water Further conditioning of the UF-concentrate by evaporation / distillation as pre-stage for external disposal Advantages of the process: Recovery of dyes separated by tonality is possible and established Recirculation of the rinse water is possible and established Reduction of the waste water amount At existing waste water treatment plants (based on precipitation) amounts of sludge can be reduced enormously Compact and modular design Fully automized process - low personnel costs High degradation rate and efficiency (concerning CSB, Cu,

Request for a quote

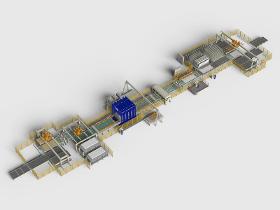

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The high-rack store is primarily for linking board production with the downstream processing systems. Formatted raw-board stacks from board production and boards with papers for board lamination are stored intermediately in the high-rack store and delivered to the downstream systems as required. The high-rack store may be installed separately or combined with complete transport systems for connection to the production systems. Tailored to customer requirements, the high-rack store is designed with all the components needed for storage / removal and connection to the production facilities. Our goal: to achieve the best product in all forms through the optimum use of resources! The machines used are tailored in the best way possible to the products, the required capacity and interactions. It is possible to take account of extension stages from the start. Advantages Optimum use of space Safe and gentle material transport

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Papers and carrier boards are combined in the batch laying section. In the simplest of cases, a batch that is ready for pressing consists of a sheet of decorative paper as the base layer, a carrier board and a sheet of decorative paper as the top layer. It may in certain circumstances be necessary to use of several types of paper. Features, function Papers soaked in resin are supplied to the plant in sheets lying on pallets. A suction bar separates the papers from the stack and pulls them on to a laying conveyor. A suction carriage delivers the board made from wood-based material. The laying conveyor conveys the batch from laying station to laying station / conveys the assembled batch to the facility core. The batch is statically charged in order to secure the papers on the carrier board for continued transport. Advantages The individual layout of the batch layer is based on coordinated standard modules.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Short-cycle presses are for rening the nishes on boards made from woodbased materials. Accordingly sanded particleboards and MDF / HDF with smooth nely pored surfaces are particularly suitable. Features, function A hot press is used to permanently apply resin-soaked paper to the surfaces of boards made from wood-based mate pores and in this way is responsible for adhesion. It also creates a surface that is resistant to a variety of environment for the colourless resin and for the decorative layer.

Request for a quote

SCHMEDT GMBH & CO. KG

Germany

We manufacture machines for making books with hardcover and supply more than 10.000 articles such as board, paper, cloth, glue, adhesives to make books with hardcovers

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Paper boards - Import exportNumber of results

5 ProductsCountries

Company type