- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- palletising machinery

Results for

Palletising machinery - Import export

TRAPO GMBH

Germany

With decades of know-how and worldwide expertise in the core areas of conveyor technology, robot systems, palletizing, depalletizing and automation, TRAPO AG presents itself as a renowned manufacturer and total systems supplier of conveyor systems, palletizing technology and packaging machines. Primary and secondary packaging such as cartons, trays, pails and more are palletized and depalletized. The machines in our systems impress with their flexibility, high performance and economic efficiency. We produce in Germany and set standards worldwide ranging from engineering contracts to automation. The palletizers of the HLP series operate with high and low inlet. The product range of the high-capacity layer palletizers is optionally equipped with a y-axis, rotary module or even a traversing axis — so that one or more palletizing stations can be operated as required.

Request for a quote

ERGOPACK DEUTSCHLAND GMBH

Germany

713X \ 726X \ 745X – WITH ELECTRONICALLY CONTROLLED DRIVE & CONTROL VIA JOYSTICK – LITHIUM BATTERY – CHARGER – LINE LASER – ERGOPACK TOOL-LIFT – SEALING TOOL – CONTROL VIA INDUSTRY TOUCHSCREEN INTERESTED? WE WOULD BE HAPPY TO VISIT YOU AND CONFIGURE THE SYSTEM INDIVIDUALLY WITH YOU ON SITE. 700X WITH ELECTRONICALLY CONTROLLED DRIVE & CONTROL VIA JOYSTICK LITHIUM BATTERY CHARGER CONTROL VIA INDUSTRY TOUCHSCREEN

Request for a quote

ERGOPACK DEUTSCHLAND GMBH

Germany

713E \ 726E \ 745E WITH – ELECTRONICALLY CONTROLLED DRIVE & CONTROL VIA JOYSTICK – 24V AGM BATTERY PACK – CHARGER – ERGOPACK TOOL-LIFT – SEALING HEAD We will be happy to discuss the individual configuration of your system in person after a product demonstration at your site. 700E WITH – ELECTRONICALLY CONTROLLED DRIVE & CONTROL VIA JOYSTICK – 24V AGM BATTERY PACK – CHARGER We will be happy to discuss the individual configuration of your system in person after a product demonstration at your site. 700 WITH – MANUALLY DRIVE VIA A HAND CRANK We will be happy to discuss the individual configuration of your system in person after a product demonstration at your site.

Request for a quote

VARIOTECH GMBH

Germany

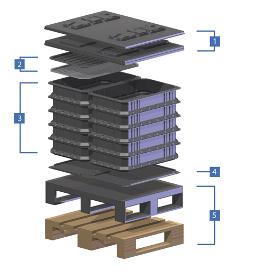

Returnable tray Developed for the costefficient and safe cleaning of work pieces Frames are lightweight and easy to handle – Interior workings are as individual as most efficient.

Request for a quote

VARIOTECH GMBH

Germany

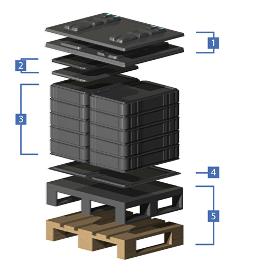

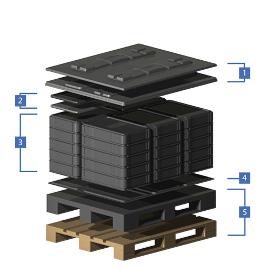

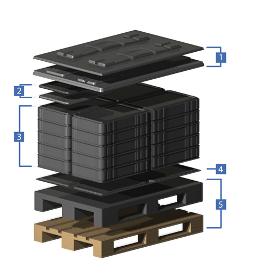

Pallet lid with water drainage function (Frog) 2) Heightneutral lid (ca. 15 mm recess) Lid with no recess Locking lid 3) Frames with euro palletcompatible surface areas 400 x 300 mm (4 unit) 600 x 400 mm (2 unit) 800 x 600 mm (1 unit) 4) Securing plate for wood or plastic pallets without safety edge 5) Wood pallet, plastic returnable pallet or returnable pallet

Request for a quote

VARIOTECH GMBH

Germany

Pallet lid with water drainage function (Frog) 2) Heightneutral lid (ca. 15 mm recess) Lid with no recess Locking lid 3) Frames with euro palletcompatible surface areas 400 x 300 mm (10 unit) 600 x 400 mm (5 unit) 600 x 500 mm (4 unit) 1200 x 1000 mm (1 unit) 4) Securing plate for wood or plastic pallets without safety edge 5) Wood pallet, plastic returnable pallet or returnable pallet

Request for a quote

VARIOTECH GMBH

Germany

Pallet lid with water drainage function (Frog) 2) Heightneutral lid (ca. 15 mm recess) Lid with no recess Locking lid 3) Frames with euro palletcompatible surface areas 400 x 300 mm (8 unit) 600 x 400 mm (4 unit) 800 x 600 mm (2 unit) 1200 x 800 mm (1 unit) 4) Securing plate for wood or plastic pallets without safety edge 5) Wood pallet, plastic returnable pallet or returnable pallet

Request for a quote

VARIOTECH GMBH

Germany

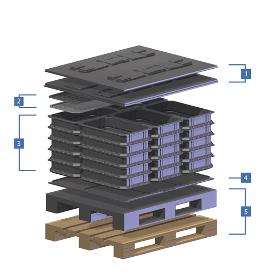

Returnable tray Developed for the efficient and safe transport of large and heavy work pieces Frames optimized for gripper arms – Interior workings as individual as most efficient for the packing density.

Request for a quote

VARIOTECH GMBH

Germany

Pallet lid with water drainage function (Frog) 2) Heightneutral lid (ca. 15 mm recess) Lid with no recess Locking lid 3) Frames with euro palletcompatible surface areas 400 x 300 mm (4 unit) 600 x 400 mm (2 unit) 800 x 600 mm (1 unit) 4) Securing plate for wood or plastic pallets without safety edge 5) Wood pallet, plastic returnable pallet or returnable pallet

Request for a quote

VARIOTECH GMBH

Germany

Pallet lid with water drainage function (Frog) 2) Heightneutral lid (ca. 15 mm recess) Lid with no recess Locking lid 3) Frames with euro palletcompatible surface areas 400 x 300 mm (10 unit) 600 x 400 mm (5 unit) 1000 x 600 mm (2 unit) 4) Securing plate for wood or plastic pallets without safety edge 5) Wood pallet, plastic returnable pallet or returnable pallet

Request for a quote

VARIOTECH GMBH

Germany

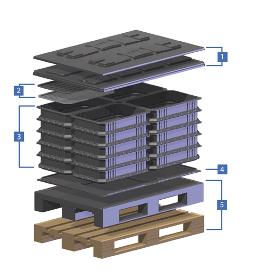

Pallet lid with water drainage function (Frog) 2) Heightneutral lid (ca. 15 mm recess) Lid with no recess Locking lid 3) Frames with euro palletcompatible surface areas 400 x 300 mm (8 unit) 600 x 400 mm (4 unit) 800 x 600 mm (2 unit) 1200 x 800 mm (1 unit) 4) Securing plate for wood or plastic pallets without safety edge 5) Wood pallet, plastic returnable pallet or returnable pallet

Request for a quote

VARIOTECH GMBH

Germany

Returnable tray Developed for the efficient and safe transport of large and heavy work pieces Flexresistant and selfsealing frame for optimal stackability – Interior workings as individual as most efficient for the packing density.

Request for a quote

VARIOTECH GMBH

Germany

Oneway tray Developed for the costefficient transport of work pieces Frames are stackable as a tray or have a collapsible design – Interior workings as individual as most efficient.

Request for a quote

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Economic articulated arm robot alternative • Conversion of braking energy into electrical current saves resources and the environment • Easy and cost saving installation as no support foundation is required • Easy operation due to clearly defined working area • Flexible application due to compact and modular design • Open control system allows for the installation of new pallet configurations at any time The Linear Robot LR03 is a flexible palletizer and an economical solution for palletizing almost all products in the consumer goods industry and is ideally suited for palletizing bundles, boxes, bags, standard cases, bakery baskets and packs. In situations with low ceilings and limited space it is the perfect fit. The LR03 impresses with its solid construction, use of high quality components and maintenance friendly design and ensures easy operation. This robot sets standards with a load capacity of up to 500 kg and a possible palletizing height of up to 2800 mm.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Optimal use of space due to its compact design • Reduction of the footprint by more than 40% in comparison to fork gripper systems • Gentle handling of complete product layers • Handling of a variety of pallet configurations with only one gripper • Format parts are not required, thus reducing complexity and freeing warehouse space TheWave is a unique combination of a conveyor element with a layer gripper resulting in a machine that can take complete product layers arriving from the conveyor lane and – independent of product type and configuration – place them safely onto a pallet. TheWave can be used in all sectors of the consumer industry branch and for almost all products. Its compact design makes it possible – in contrast to the usual systems using fork or clamp grippers – to save enormously on floor space.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Easy operation and monitoring from floor level • Easy and quick product changes due to tool-less format changeovers • Small footprint allows for integration into existing production lines • Modular design eases adaptation to a variety of requirements • Extendable through the Langhammer building block system The Layer Palletizer PA7 is ideal for universal use in the middle class range and for a large variety of applications and products - such as cartons, bags, packs, containers, plastic cases etc. A typical application is its use as a line palletizer placed downstream from packaging machines, e. g. in the food industry. A variety of infeed versions and the patented integrated interleaf unit allow for a wide range of possibilities. For example, bags within a performance range of up to 1000 per hour can be palletized perfectly. The electrically driven gripper turning unit operates form-fittingly which makes for exact 90 degree right or left turns or 180 degree ones.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Complete building block system with modular standard components • Individually planned conveyor units, fine-tuned to task requirements • Large assortment of pallet transport technology: • Pallet Roller Conveyors • Pallet Chain Conveyors • Pallet Buffer Conveyors • Pallet Turntables • Pallet Transfer Units • Pallet Shuttle Cars • Empty Pallet Dispensers • Empty Pallet Testers • Pallet Lifts Just some of the tasks for which Langhammer offers the right solution: stacking or separating empty and full pallets, transporting pallets on different transport levels, a wide range of roller conveyors available up to driven roller conveyors with reversible transport direction and high pulling power, driven roller conveyors for lowest building heights, transfer units and turntables enable flexible pallet transport, connect transport lines and change transport direction of the pallet as required.

Do you sell or make similar products?

Sign up to europages and have your products listed

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Quick throughput times, high processing exactness as well as improved working conditions through optimally planned material flow • Compatible components reduce interfaces • Large assortment of standard components: Belt Conveyors: • Curved Belt Conveyors • Small Belt Conveyors • Inclined Belt conveyors Roller Conveyors: • Wheel Conveyors • Light Roller Conveyors • Roller Conveyor Curves • Gravity Roller Conveyors • Driven Roller Conveyors Chain Conveyors: • Chain Conveyors • Traction Lifts Product transportation is an essential element of in-plant logistics. Exact and precise handling is a prerequisite for optimal material flow. Belt conveyors are ideal for transporting light to moderately heavy products. Roller conveyors can be adapted to a variety of space conditions. They are used for transporting light as well as heavy products, are impervious to dust and thus ideal for use in dusty environments.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Gentle transport of products and high performance due to continuous chain run • Intermediate buffering of several products possible • Up and down movement with same side or opposite side infeed/outfeed Vertical lifts make material flow across several levels possible and are used wherever goods need to be transported vertically - they are ideal for the vertical transport of boxes, trays, plastic containers, bundles, pallets, and bags within automatic conveyor systems. Vertical Lift SPF1S: Transport direction in “S” form. Outfeed side always opposite the infeed side. Vertical Lift SPF1C: Transport direction in “C” form. Outfeed side always on the infeed side.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • High uptimes due to maintenance-free guidance of the main axes • Low headroom with telescoping axis/option • Handling of very heavy loads with rigid Z-axis/option • Highly flexible due to the use of a variety of grippers • Interleaf + pallet handling possible The Gantry Robots can be used for almost all products such as bundles, boxes, bags, standard cases, bakery baskets and packs. Equipped with a maintenance-free axis system, strong lifting axis or telescopic lifting axis they are predestined for heavy-duty usage. What characterizes our gantry robots is their high flexibility, wide operating range and precision in handling. They meet the requirements needed for increasing the variety of handled products. In this way unit costs are optimized and processing safety heightened. The system's flexibility increases the machine's uptime and makes it possible to react faster to market requests. These robots offer a flexible, reliable and economical automatic solution.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Highly flexible palletizing solutions due to quick and easy re-configurations • Extremely precise operation ensures high quality palletizing • Use of a great variety of grippers makes for high flexibility • Coordinated concept including material flow environment Articulated Arm Robots offer highly flexible palletizing possibilities and are thus a real economical alternative. Especially profitable when with the corresponding performance two end packaging lines can be palletized by one machine. Articulated Arm Robots from Langhammer come delivered with the complete material flow environment in exact accordance with customer preferences. A turnkey installation from a single source.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • High output rate with a wide product range • Precise operation allows for the direct production of sales pallets • Simple and quick product changeovers due to toolless format changes • Minimum space requirement facilitates the integration of the machine into existing production lines • Modular palletizer design adapts easily to any given layout • Extendable through the Langhammer building block system The Layer Palletizer PA8 is suitable for almost all consumer products in packs, cases, crates, bags, etc. The palletizer versions PA81 and PA82 are based on the PA8 base model. PA81 can carry heavy pallet loads and the pallets run through lengthwise - important when palletizing bags. PA82 is designed to handle very heavy pallet loads and pallets can run either lengthwise or crosswise. A typical application for the PA8 palletizer is found in the Hygienic Paper Industry where the standard palletizer palletizes both bundles and small packs.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Easy programming + maintenance via the PLC: no robot programming skills required • Optimal utilization of space + considerable space saving due to compact design • Highly flexible palletizing solution allows for any number of layer patterns • Layer weights of up to 200 kg possible • Gentle product handling of complete layers • Consistent and proven Langhammer operating concept allows for easy configuration In contrast to conventional systems with fork/clamp grippers, this compact design results in an enormous space saving of up to 40%. The new Articulated Arm Robot AR500 in combination with either Siemens or Rockwell controls guarantees easiest programming and maintenance directly via the PLC. By combining the Articulated Arm Robot AR500 with TheWave Langhammer offers a coordinated concept for the complete material flow, characterized by extreme accuracy & high-quality palletizing – and everything according to customer requirements – ready to go from a single source

ROTEG AG ROBOTER TECHNOLOGIE

Germany

The palletizing robot system PARO® has a modular structure. This is how the palletizing room can be optimally adapted to the palletizing task – even afterwards. The spectrum ranges from standard single place cells which are not bigger than the pallet itself, to palletizing systems with twelve or more palletizing stations. All of this is easily determined by a correspondingly long horizontal axis. The palletizing robot PARO® is a four-axis robot whose axis have a special guide system: Profiled, teflon coated Vulkollanrollers run on polished stainless steel tubes. This system has proven itself to be robust and maintenance free. With this simple system technology a lot of industrial handling processes are economically automated in different performance areas. The PARO® is durable and also suitable for the use in extreme enviroments. All in all the robot offers a good price-performance ratio.

Request for a quoteResults for

Palletising machinery - Import exportNumber of results

25 ProductsCountries

Company type

Category