- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packaging containers

Results for

Packaging containers - Import export

SPIES PACKAGING / SPIES KUNSTSTOFFE GMBH

Germany

Resource-saving, sustainable and future-oriented. In addition to a well-working recycling process, a functioning circular economy also requires extensive possibilities for using the recycled material. The use of mechanically recycled post-consumer recycled material is not yet feasible in the food industry at the present time and is prohibited by law. Outside the food industry, however, there are already various areas of application. Your desired article geometry can be developed individually.

Request for a quote

SPIES PACKAGING / SPIES KUNSTSTOFFE GMBH

Germany

The ""digital watermark"" integrated into the whole packaging allows the machines in the sorting plants and the end consumer to find out more information about the packaging via an app using their smartphone. In this way, sorting plants can differentiate between food packaging and packaging for chemicals, for example, and sort them according to their intended use. Your desired article geometry can be developed individually.

Request for a quote

SPIES PACKAGING / SPIES KUNSTSTOFFE GMBH

Germany

Long lasting, reusable and full of information - the new SPIES smart RFID technology turns ordinary injection molded items into smart reusable products. As an alternative to disposable items, it is our answer to the ban on disposable plastic items and singleuse packaging to protect our environment. Your desired article geometry can be developed individually.

Request for a quote

SPIES PACKAGING / SPIES KUNSTSTOFFE GMBH

Germany

Following the market trend, the new SPIES PC meets all requirements - from weight optimization and resource conservation to the use of renewable raw materials. Your desired article geometry can be developed individually.

Request for a quote

MALEKI GMBH

Germany

Abrasion resistant sealant for industrial floors with high surface strength. Increases the chemical resistance of the substrate. Maleki-VS 930 is also used as a system product for unpolished Lithokor design floors. Packaging unit: 7 kg container (single), other packaging sizes on request – Article-No.: 1828

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

With the docking station solution, your air cushion machine AirWave1/2 is able to show its performance. No volume is too large for rapid filling. Thanks to the fast and automated operation, the docking station will fill one container after another. Package contents: Mobile table (LxBxH: 50x50x121 cm) Rolling basket (LxBxH: 90x60x140 cm) Infrared sensor for the AirWave1/2

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

Probe for easy sampling from closed containers or packaging Ideal for the analysis of gases in sample bags, for example

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

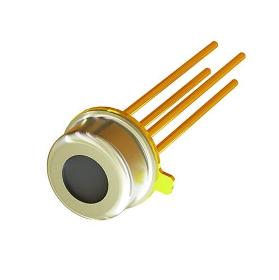

The MEMS-based MTS1TEMP56 detects infrared radiation for non-contact temperature measurement. The 56 silicon thermopiles absorb the incoming radiated energy. The integrated mass absorber ensures the efficient conversion of the radiated energy into thermal energy. The thermocouples convert this thermal energy into electrical energy, which is output as a measurement signal. The single channel thermopile is the best choice for mass applications with quantities above 50000 pieces per year in medical and life science applications or in building automation. The TO46 package with small dimensions makes this component especially suitable for mobile devices. With a detectivity up to 0.67 *10^8 cm√Hz/W as well as a sensitivity up to 31 V/W, the materials offer reliable measurement results at a very good price/performance ratio. Nitrogen was used as backfill gas and a filter with a transmission cut on 5.5 µm. ATTENTION: 1 piece packaging unit contains 200 detectors each!

Request for a quote

OGE GROUP

Germany

This easy-to-install, self-contained package includes a solenoid-operated, single revolution clutch with anti-rollback and anti-overrun features.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Raising the container when filling to prevent dust accumulation - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport - Very gentle processing of the containers and packaging - Processing different container shapes Manufacture/Closing: - Simple integration into existing packaging technologies - Process-reliable sealing using thermal sealing, induction or ultrasound is possible - Processing all standard types of caps

OPTIMA CONSUMER GMBH

Germany

Containers: - Container classification via the infeed screw - Container transport using pucks for flexible production and fast conversion - Cycled container transport - Continuous container transport - Very gentle processing of the containers and packaging - Processing different container shapes Shapes: - User-friendly, fast and primarily tool-free format change - Fully or semi-automated format change is optional

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification via the infeed screw - Container transport using pucks for flexible production and fast conversion - Continuous container transport -Optimized container transport for preventing splashing in little headroom - Very gentle processing of the containers and packaging - Processing different container shapes Design: - Can be designed as a monobloc combination with filling and sealing modules - Good visibility and accessibility - Integrated separation for reject product and/or production patterns - Compact design with low space requirement - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system Manufacture/Closing: - Simple integration into existing packaging technologies - Processing all standard types of caps

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Raising the container when filling to prevent dust accumulation - Container transport using pucks for flexible production and fast conversion - Centering the container for the optimal positioning of the containers below the work stations - Cycled container transport - Optimized container transport for preventing splashing in little headroom - Very gentle processing of the containers and packaging - Processing different container shapes Manufacture/Closing: - Simple integration into existing packaging technologies - Process-reliable sealing using thermal sealing, induction or ultrasound is possible - Processing all standard types of caps - Processing packaging material from the stack

OPTIMA CONSUMER GMBH

Germany

Containers: - Container or cap feed as bulk goods via fully automatic sorting and optional storage bin - Container classification via the infeed screw - Continuous container transport - Optimized container transport for preventing splashing in little headroom - Very gentle processing of the containers and packaging - Processing different container shapes Shapes: - User-friendly, fast and primarily tool-free format change Design: - Can be designed as a monobloc combination with filling and sealing modules - Good visibility and accessibility - Integrated separation for reject product and/or production patterns - Min./max. Sensors for jam detection upstream and downstream of the machine - Secure and sturdy mechanical system Manufacture/Closing: - Processing all standard types of caps

SCHÖNWOLF HAMBURG BY 7 SOLUTIONS GMBH

Germany

Maximum measurement accuracy with simple operation Dräger tubes are calibrated short-time rapid measurement system, which determines quickly and inexpensively various gas concentration currently. With easy operation highest measurement accuracy for gases, vapours and aerosols is achieved. Individual- and simultaneous measurements are possible, either air or technical gases and in water or bottom sludge. During the shelf-life (normally 2 years) no calibration is necessary. Several measurements with only Dräger tube are particularly possible Generally one package contains 10 Dräger-tubes (PU), some articles contain fewer tubes, but then the deviating number is stated in brackets. Dräger tubes indicate standard measuring range; any possible deviation of measuring range can be read in instruction for use. With short time measurements, the indicated measuring time refers to stated number of strokes for each tube. If the measurement time is less than 1 minute, the time record is...

Request for a quoteResults for

Packaging containers - Import exportNumber of results

16 ProductsCountries

Company type