- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packaging automation

Results for

Packaging automation - Import export

ENOL FOLIEN GMBH

Germany

Our flat foil is used for automatic packaging processes. It is suitable for standard use or special packaging solutions. We deliver the flat foil adjusted to your existing machinery in order to safeguard fast and secure packaging without any disturbances. Our foils are offering longterm protection of your products, especially because of high welding stability. ENOL flat foils can be delivered with or without printing in different materials, like PP (OPP, PPCoex, PPCast), PE (LDPE, HDPE, MDPE), metallised (ALU), pearlised OPP and PET in every width and foil thickness. For each product to be packed you can receive the suitable packaging foil – also laminated with PET or PA in order to provide longer freshness of the packed product or to provide more stability of the foil for industrial processing width, material thickness, rapports according to your requirements for industrial processing food genuine material PP (OPP plain, OPP Coex, metallised OPP, CPP), PE, PET laminated if...

Request for a quote

ROLLON GMBH

Germany

The ECO SYSTEM units are linear actuators made of a self-sustaining extruded aluminum frame and are driven by a polyurethane belt with AT metric profile steel inserts. Three different sizes available: 60mm, 80mm, 100mm Version available with recirculating ball bearing or roller rails Reduced weight ensured by the light frame and the aluminum sliders High sliding speed The ECO SYSTEM series actuators are offered with two motion systems: ECO SYSTEM – SP Featuring a maintenance free recirculating linear guide rail fitted inside the profile. ECO SYSTEM – CI Featuring four rollers with a Gothic arch outer profile sliding on hardened steel bars placed inside the profile. Main fields of application for Eco System linear units: Automation Packaging Industrial machinery

Request for a quote

ENOL FOLIEN GMBH

Germany

Our foil packaging for bread and bakery products is available as bags for filling by hand or machine and also as flat foils for your automated packaging lines – the perfect protection for uncut / cut bread, toast, cake, cookies, bread to heat up as well as croissants. Available foils are PP (OPP plain, OPP Coex, PPCast) LDPE laminations according to your requirements – also with PET / PA to meet requirements regarding barrier for freshness. The raw materials are special type for the use regarding bread and bakery products. The flat foils are made suitable individually for your machines to ensure a proper packaging process without any disturbances / interruptions. Our foils are certified as food safe are steadily checked reagarding possibilities to sterilisation, stability as well as stability of the seams. bag sizes, foil widths, rapports and materials acc. to your specifications unprinted or printed up to 10 colours in good flexo- or gravure printing quality Following bag...

Request for a quote

IGUS® GMBH

Germany

iglidur® knife edge rollers Precise and lubricant-free deflection igus® has developed its own knife-edge conveyor pulleys to implement conveyor belt deflection for conveyor technology applications. The first standard product range has three iglidur® materials available: the universal iglidur® P210 and the FDA compliant iglidur® A180 (up to 90°C) and iglidur® A350 (up to 180°C). The iglidur® solution is characterized by tight deflection radii and low essential driving power. Complete freedom from the lubricant of the belt deflection Low driving power Tight deflection radii Long service life of the belt Cost-effective High holding times Application areas: Packaging, material handling, automation, food processing. Brochure (PDF) Shaft diameter d1 [mm]: Knife-edge conveyor pulley application example Precise and lubricant-free deflection igus® has developed its own knife-edge conveyor pulleys to implement conveyor belt deflection for conveyor technology applications. The first standard product range has three iglidur® materials available: the universal iglidur® P210 and the FDA compliant iglidur® A180 (up to 90°C) and iglidur® A350 (up to 180°C). The iglidur® solution is characterized by tight deflection radii and low essential driving power. Complete freedom from the lubricant of the belt deflection Low driving power Tight deflection radii Long service life of the belt Cost-effective High holding times Application areas: Packaging, material handling, automation, food processing. Brochure (PDF) Shaft diameter d1 [mm]: Soft stainless steel Hard stainless steel

Request for a quote

MULTIVAC SEPP HAGGENMÜLLER SE & CO. KG

Germany

With automatic lines for slicing and packing sausage, ham and cheese products, MULTIVAC realizes the optimal connection of slicers to thermoforming packaging machines and traysealers.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WEBER FOOD TECHNOLOGY GMBH

Germany

The perfect thermoformer for packing your sliced products Whatever you slice – wePACK: Right from the start, the development of the wePACK was focused intently on the requirements of our customers. The result is a packaging machine which is consistently geared to slicing applications and which delivers maximum output, as well as ease of operation and servicing. Thanks to its hygienic design and a high level of automation, the wePACK guarantees maximum food safety. From product preparation to quality checked primary packaging, we offer everything from a single source. This unique situation takes the integration of slicers, automation, packaging and end-of-line equipment to a new level. Weber combines strong single components to even stronger complete line solutions. The boundaries between individual components disappear, so that the complete slicing line merges into one unit. NEW: Optimized software for the integration of infeeding systems

Request for a quote

GORDOPACK GMBH

Germany

For protecting and preserving your goods, flat film packing of Gordopack is your best option. Our flat film of our company covers the needs of a wide range of applications in private households, but also in industry and trade. The flat films are suitable for manual or automated packaging of goods as well as for covering and protecting various goods. The assortment of flat films ranges from asparagus foils, flow packaging films to top sheets. According to our customers' wishes, we also equip the flat films with technical additives and colours Product can range from HDPE/ MDPE/ LDPE/ PCR with straight-cut edges, perforated on roll, needled, with antistatic agent, UV-stabilizer/absorber, symbol marking, Corona treatment and in various colours.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

Logistic centers often work with automated package systems. If the goods slip back and forth, they will not stop in the packaging and the entire carton may fall off the conveyor belt. The solution: air cushion! They ensure reliable stablity.

Request for a quote

EXCOR KORROSIONSSCHUTZ-TECHNOLOGIEN UND -PRODUKTE GMBH

Germany

All EXCOR VALENO Flat Film can be used in automated packaging processes. Made from polyethylene, it has a wide range of applications, for instance as interleaving sheets and for wrapping and lining purposes. The EXCOR VCI substance is integrated into the polymer matrix. The anti-corrosion effect is long-term and active over large areas.

Request for a quote

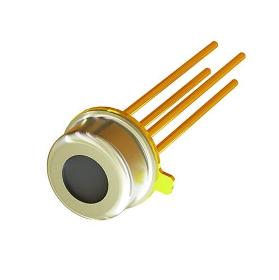

MICRO-HYBRID ELECTRONIC GMBH

Germany

The MEMS-based MTS1TEMP56 detects infrared radiation for non-contact temperature measurement. The 56 silicon thermopiles absorb the incoming radiated energy. The integrated mass absorber ensures the efficient conversion of the radiated energy into thermal energy. The thermocouples convert this thermal energy into electrical energy, which is output as a measurement signal. The single channel thermopile is the best choice for mass applications with quantities above 50000 pieces per year in medical and life science applications or in building automation. The TO46 package with small dimensions makes this component especially suitable for mobile devices. With a detectivity up to 0.67 *10^8 cm√Hz/W as well as a sensitivity up to 31 V/W, the materials offer reliable measurement results at a very good price/performance ratio. Nitrogen was used as backfill gas and a filter with a transmission cut on 5.5 µm. ATTENTION: 1 piece packaging unit contains 200 detectors each!

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The fully automated packaging of the nished product stacks constitutes an additional facet of the performances we provide to our customers. This type of automation creates the optimum packaging solution for transport, storage and further processing – from the simple securing of loads to weatherproof packaging that is ready for dispatch. The dierent procedures may be employed and exibly combined in the line in accordance with the customer's requirements. The following packaging methods are available to this end, among others: The dierent procedures may be employed and exibly combined in the line in accordance with the customer's requirements. The following packaging methods are available to this end, among others: Features and functions Complete stack handling, stack separation or merging Variable packaging solution, tailored to the product Full range of performances from simple load securing to weatherproof packaging that is ready for dispatch

Request for a quoteResults for

Packaging automation - Import exportNumber of results

12 ProductsCountries

Company type