- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- nickel and alloys

Results for

Nickel and alloys - Import export

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

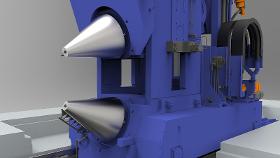

To address the most stringent demands in terms of cutting output, high precision, automation and process reliability BEHRINGER HBM series high-performance automatic bandsawing machines offer an impressive package of benefits, guaranteed not only by their vibration-damping structure made of grey cast iron components and the saw frame with its centric flow of forces. The sensitive BEHRINGER feed control also helps protect the saw blade, ensuring even greater economy through a long tool service life. By using a servo feed system, a high cutting performance is achieved when sawing tool and stainless steels and materials such as Hastelloy or Inconel with difficult machining properties. A highly efficient chip brush system cleans the saw blade on both sides from any adhering sawing chips.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

CuNi3Si alloy with very good bendability, very good hot and cold forming properties, a high strength and a good corrosion resistance. Perfect material for Connectors, bent parts, relays.

Request for a quote

PRESSTECK S.P.A.

Germany

We are experts in deep-drawn parts made of stainless steel, deep-drawn parts made of aluminium and other non-ferrous metals (including brass, copper and nickel silver). To produce your perfect component, we also have the option of using carbon steel, special nickel alloys (e.g. Inconel®), but also soft magnetic materials. Each material has specific properties that need to be taken into account in the forming process. We manufacture deep-drawn parts with a diameter of 2 to 80 mm and a length of up to 120 mm. We process material thicknesses from 0.05 to 2.50 mm. Pharmaceuticals and medical technology, industry, consumer and automotive: we are primarily active in these fast-growing sectors. We are not only specialists in deep drawing, but also know the industrial requirements and process chains. Depending on your requirements, we complement deep-drawing with numerous secondary finishing processes up to fully automated assembly systems.

Request for a quote

PRESSTECK S.P.A.

Germany

We are experts in deep-drawn parts made of stainless steel, deep-drawn parts made of aluminium and other non-ferrous metals (including brass, copper and nickel silver). To produce your perfect component, we also have the option of using carbon steel, special nickel alloys (e.g. Inconel®), but also soft magnetic materials. Each material has specific properties that need to be taken into account in the forming process. We manufacture deep-drawn parts with a diameter of 2 to 80 mm and a length of up to 120 mm. We process material thicknesses from 0.05 to 2.50 mm.Pharmaceutical and medical technology, industry, consumer and automotive: we are primarily active in these fast-growing sectors. We are not only specialists in deep drawing, but also know the industrial requirements and process chains. Depending on your requirements, we complement deep-drawing with numerous secondary finishing processes up to fully automated assembly systems.

Request for a quote

DR.-ING. MAX SCHLÖTTER GMBH & CO. KG.

Germany

Electroplated metal surfaces are found in all areas of daily life and are used not only for technical purposes but also for decorative ones. For this, metallic coatings made of copper, nickel, nickel alloys, chrome, silver, and gold are used, which can offer both a matte and a high-gloss appearance. The most common application areas for decorative surfaces are found in the automotive industry, in sanitary areas for items such as fittings, but also in the consumer goods industry, thus combining functionality with appealing aesthetics.

Request for a quote

BDSENSORS GMBH

Germany

The pressure transmitter DMK 457 with ceramic sensor has been designed for typical applications in shipbuilding and offshore constructions as alternative to our pressure transmitter DMP 457 with piezoresistive stainless steel sensor. In combination with the copper-nickel-alloy the DMK 457 is suitable for seawater, e.g. level measurement in ballast tanks, etc. Features: — nominal pressure: 0 ... 400 mbar up to 0 ... 600 bar — accuracy: 0.5 % FSO — shipping approvals GL (Germanischer Lloyd), DNV (Det Norske Veritas), CCS (China Classification Society), ABS-certificate (American Bureau of Shipping), LR-certificate (Lloyd´s Register) — pressure port CuNiFe (sea water resistant) — oxygen application Optional Features: — IS-Version Ex ia = intrinsically safe for gases and dusts

Request for a quote

EWM AG

Germany

EWM welding consumables for MIG/MAG welding Welders can choose between different welding rods with different diameters and materials to work with: — unalloyed steels — low-alloy steels — high alloy steels — Nickel-based materials — aluminium alloys — Copper-based materials — Hardfacing

Request for a quote

EWM AG

Germany

EWM welding consumables for MIG/MAG welding Welders can choose between different spool sizes with different wire diameters and materials to work with: — unalloyed steels — low-alloy steels — high ally steels — Nickel-based materials — aluminium alloys — Copper-based materials — Cladding

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Stainless steel • Heat resistant steels • Cold and hot working steels • Hardened steel up to 1900 N/mm2 • Nickel based alloys • Aluminium-silicon alloys • Copper-nickel alloys • Titanium and titanium alloys • Exotic, hard to cut alloys

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Steels of the highest tensile strength • Long chipping materials • Stainless steel • Titanium based alloys • Nickel based alloys • Special bronzes

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • hard and tough materials up to 1700 N/mm2 tensile strength • Stainless steel • heat resistant duplex steel • nickel based alloys • aluminium alloys • titanium bades alloys

Request for a quote

CARBO-WELD SCHWEISSMATERIALIEN GMBH

Germany

Solid wire electrode suitable for joining and surfacing alloys of similar composition with up to 30% nickel as well as non-ferrous alloys and dissimilar steel grades. The deposit weld metal is highly resistant to seawater, typical applications include usage in shipbuilding, oil refineries, food processing industry, the engineering of general corrosion proof vessels and equipment.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our open-die forging presses play an important part among the forming presses. Siempelkamp supplies complete open-die forging presses equipped with manipulators and ancillary equipment such as lifting turntables and quite a number of additional components. Our presses operate reliably, fast and precisely, operating at pressing forces between 10 and 160 MN. The range of presses available comprise push-down or pull-down designs, two- or fourcolumn designs with oil-hydraulic or water-hydraulic drives. High-stroke frequency contributes to the eciency of these presses. Our customers produce bars, discs, rings, and anges from materials such as steel, high-alloy steel, nickel-based alloys, titanium, and aluminium on these presses. They prefer to order turn-key plants including integrated manipulators, turntable, die magazine, and die-changing system.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

With the ring rolling mill Siempelkamp completes its range of products for the manufacture of rings. From forging the pre-forms to manufacturing the ring blanks to ring rolling, we supply everything from a single source. Siempelkamp’s ring rolling mill manufactures seamless rings made of steel and special materials such as nickel-base, titanium, or aluminium alloys using maximum radial and axial pressing forces. The radial pressing force is hydraulically generated and applied to the part via a mandrel roll. Radial rolling is carried out by reducing the roll gap between the driven external roller and the mandrel roll. The axial pressing force is also hydraulically generated and applied to the part via the upper axial roller. Axial rolling is carried out by means of the vertical forward feed of the upper axial roller. A centring device provides for the correct position of the ring during the rolling process.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BÖLLINGHAUS STEEL GMBH

Germany

Stainless steel types: Austenitic Duples Ferritic Martensitic Nickel alloys Titanium

Request for a quote

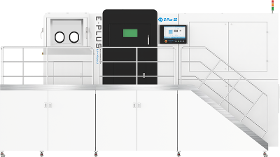

EPLUS3D TECH GMBH

Germany

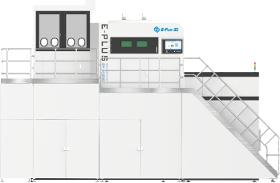

Using MPBF (Metal Powder Bed Fusion) technology, the EP-M1250 is using a 1258 x 1258 x 1350 mm3 build envelope and nine laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase. The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Maraging Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is suitable for the direct manufacturing of largesize, high-precision and high-performance parts in the aerospace, aviation, automotive and machinery industry.

Request for a quote

EPLUS3D TECH GMBH

Germany

Using MPBF (Metal Powder Bed Fusion) technology, the EP-M650 is using a 655x655x800mm3 build envelope and quad laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase. The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Maraging Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is suitable for the direct manufacturing of large-size, high-precision and high-performance parts in the aerospace, aviation, automotive and defense industry.

Request for a quote

EPLUS3D TECH GMBH

Germany

With a building chamber size of 455*455*500mm Eplus3D Introduces EP-M450 to the successfulline of MPBF™ 3D printers. The complete open systemmakes EP-M450 a very powerful tool for large scaleproduction for our customer to access different metal powders like titanium, aluminum, nickel alloys and stainless steel, etc. EP-M450 is aiming to output the large parts with its high performance and high accuracy.

Request for a quoteResults for

Nickel and alloys - Import exportNumber of results

22 ProductsCountries

Company type

Category

- Forming - steels and metals (3)

- Hand tools, non-power (3)

- Printers - computer (3)

- Welding work - steels and metal (2)

- Steels, nickel (1)

- Copper and copper alloys (1)

- Chemicals - Basic Products & Derivatives (1)

- Iron alloys (1)

- Measurement and regulation equipment and instruments - pressure (1)

- Rolling mills - ferrous metals (1)

- Sawing machine tools (1)

- Steel, special (1)

- Wires and cables - ferrous metal (1)