- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- modules for electronics

Results for

Modules for electronics - Import export

KENDRION (VILLINGEN) GMBH

Germany

Thanks to extremely compact design the overexcitation rectifier "Slim Collection" can be installed in very restricted space. The module features a central bore for screw fixing inside the terminal box. It can also be installed by using an adhesive pad.

Request for a quote

B + B THERMO-TECHNIK GMBH

Germany

The B+B dew module is a universal, resistive evaluation electronics for detection of condensation for the dew sensors of the SHS series.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Equalize airflow pressure within speaker chambers Our POREX® porous flow modulators provide precise airflow control between speaker chambers and to the exterior of the unit, thereby reducing air pulses caused by speaker movement. Allowing a freestanding speaker system to breathe freely during temperature fluctuations, our flow modulators equalize pressure within the unit. Designed for precise airflow control, our flow modulators: Protect sensitive electronic and acoustic components–POREX® porous materials repel dust, water, sweat, oils and other liquids from entering the enclosure. Can be custom developed in three-dimensional shapes for increased design flexibility. request sample ask an engineer

Request for a quote

BDSENSORS GMBH

Germany

The pressure transmitter type DMP 333 has been especially designed for use in hydraulic applications with high static and dynamic pressure. The transmitter is characterized by an excellent long term stability, also under fast changing pressure as well as positive and negative pressure peaks. The modular concept of the device allows to combine different stainless steel sensors and electronic modules with a variety of electrical and mechanical versions.Thus a diversity of variations is created, meeting almost all requirements in hydraulic applications. Features: — nominal pressure: 0 ... 100 bar up to 0 ... 600 bar — accuracy:0.35 % (opt. 0.25 % / 0,1%) FSO — excellent long term stability, also with high dynamic pressure loads — insensitive to pressure peaks — high overpressure capability Optional Features: — IS-Version Ex ia = intrinsically safe for gases and dusts — SIL 2 version according to IEC 61508 / IEC 61511

Request for a quote

BDSENSORS GMBH

Germany

The pressure transmitter DMP 331 can be used in all industrial areas when the medium is compatible with stainless steel 1.4404 (316 L) or 1.4435 (316 L). Additional are different elastomer seals as well as a helium tested welded version available. The modulare concept of the device allows to combine different stainless steel sensors and electronic modules with a variety of electrical and mechanical versions.Thus a diversity of variations is created, meeting almost all requirements in industrial applications. Features: — nominal pressure: 0 ... 100 mbar up to 0 ... 60 bar — accuracy: 0.35 % (opt. 0.25 % / 0,1%) FSO — excellent thermal behavior — excellent accuracy — flush pressure port G 1/2" from 100 mbar Optional Features: — IS-version Ex ia = intrinsically safe for gases and dusts — SIL 2 according to IEC 61508 / IEC 61511 — pressure sensor welded — customer specific versions

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

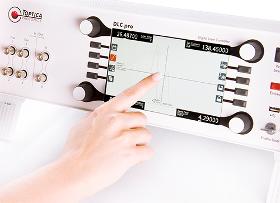

TOPTICA PHOTONICS AG

Germany

The DLC pro Lock is a software license that enables a number of features on a specific DLC pro. These allow to control the frequency of a laser for example by using a saturated absorption spectroscopy setup with a reference cell. This most popular example of frequency typically uses a modulation of the laser frequency, a de-modulation (Lock-In) for creation of the error signal and PID regulators for the generation of the error signal. All this may be achieved with a DLC pro control without further electronic modules.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The VersaMeter™ is designed to fit direction into a pipeline assembly and can provide either local or remote display options. The VersaMeter™ represents a full range of precision flow measurement instruments and accessories utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The VersaMeter™ meets current NFPA86 guidelines for safe usage in the thermal processing industry. In addition, every VersaMeter™ comes complete with a 10point calibration curve traceable to a NIST transfer standard. The meters can also be field calibrated to meet CQI-9, ISO, NADCAP and QS quality audit systems. The VersaMeter™ product line comes in...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Liquid FurnaceMeter™ is available for liquid flow measurement. These meters are fitted with integrated motorized flow control valves specifically designed for the liquid type, inlet pressures, and scale ranges to provide precision process control for most applications. The Liquid FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The Liquid FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The Liquid...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The FurnaceMeter™ is available for gas flow measurement. These meters are fitted with integrated motorized flow control valves specifically designed for the gas type, inlet pressures, and scale ranges to provide precision process control for most applications. The FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The FurnaceMeter™ meets current NFPA86...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The VersaMeter™ is designed to fit direction into a pipeline assembly and can provide either local or remote display options. The VersaMeter™ represents a full range of precision flow measurement instruments and accessories utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The VersaMeter™ meets current NFPA86 guidelines for safe usage in the thermal processing industry. In addition, every VersaMeter™ comes complete with a 10point calibration curve traceable to a NIST transfer standard. The meters can also be field calibrated to meet CQI-9, ISO, NADCAP and QS quality audit systems. The VersaMeter™ product line comes in...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The FurnaceMeter™ is available for either gas or liquid flow measurement. These meters can also be fitted with integrated manual flow control valves specifically designed for the gas type, inlet pressures, and scale ranges to provide precision process control for most applications. The FurnaceMeter™ provides a retrofit foot print to most variable area meters to minimize piping changed when upgrading to differential pressure technology and in-situ calibration capabilities. The FurnaceMeter™ represents a full range of precision flow measurement instruments utilizing our proprietary differential pressure flow measurement design proven to meet the rugged requirements of industrial heat-treatment applications. The meters utilize precision, field-proven, and certifiable differential pressure flow measurement sensors. The advanced calibration and display modules on the electronic versions include integrated flow rate alarm and flow consumption totalizing functions. The FurnaceMeter™...

Request for a quoteResults for

Modules for electronics - Import exportNumber of results

12 ProductsCountries

Company type