- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal ring

Results for

Metal ring - Import export

IDG-DICHTUNGSTECHNIK GMBH

Germany

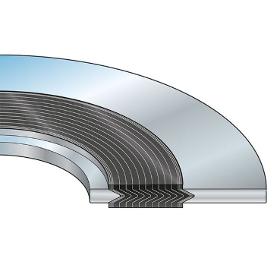

Spherical valves are installed upstream of the turbine as shutoff devices specifically for high pressures at the end of the penstock. Their main function is to close off the penstock during normal shutdown or load shedding of the turbine. The seal is a metal sliding ring which is generally moved by water hydraulics. The MANOY® system seal WP, type 434 (outer sealing) and the inner sealing type 439, were developed for sealing of the sliding ring. The profile dimensions can be customized for maintenance or specific requirements.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Circlips and Locking Rings consist of a semi-flexible metal ring with open ends that can be snapped into place. They fit in a groove on a shaft or inside a bore and locates the shaft axially in one direction.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

A snap or retaining ring is a fastener or retaining ring that consists of a semi-flexible metal ring with open ends that can be snapped into place. It fits in a groove on a shaft or inside a bore and locates the shaft axially in one direction.

Request for a quote

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

We produce hoses and technical hose products for many well-known engine and vehicle manufacturers in dimensions from 10 to 250 mm at any length and various working pressures. COUPLING Pressure-resistant hose elements as a straight connector or de-coupling element in pipelines for pressures up to 20 bar. SPIRAL HOSE Suction and pressure-resistant versions from -0.9 bar to +20 bar, with or without cuffed ends. Can also be laid in narrow radiuses. CHARGE AIR HOSE As an industrial hose, hose elbow or corrugated spiral hose for suction and pressure lines. As bellows with external metal rings in the pressure area. HOSE ELBOWS Stable shape connecting elements, either for suction and/or pressure in any geometry. Other versions and dimensions on request.

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Material Schulz Stanztechnik manufacturers these axial ball bearings using the materials suited to the specific application. For the housing, steel, brass or stainless steel are used; for rings, steel or stainless steel which is always hardened. The balls are made of chrome or stainless steel, which is also always hardened. All material combinations – depending on their conditions of use – are possible for the assembly of the individual parts. Various surface coats for the individual parts can be supplied as well as finished bearings: brass which is uncoated or nickel plated; steel and stainless steel which is uncoated, zinc plated or nickel plated. All bearings are available lubricated or unlubricated. Structure DLG100 axial ball bearings consist of sheet metal housing, two hardened rings as well as hardened precision balls. Due to their structure, we refer to them as an encapsulated, full ball design.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Spiral wound gasket made of crimped metal tape with sealing wraps of non asbestos gasket material. Optional: inner and/or outer metal ring. Characteristics For flange connections in high pressure pipe line construction and fittings Extremely low leakage with PTFE spiral. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance to 550 °C with graphite spiral Media resistance: pH 0 - 14 Max. pressure load: p = 400 bar Temperature range: t = -200 to +550 °C Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C Pressure: p = 400 bar Main application High temperature and high pressure flanges Piping Pressure vessels Heat exchangers Fittings Suitable for Power plants Petrochemical plants Chemical industry Material Centerring ring OD: Carbon Steel galvanized Spiral: 316L Centerring ring ID: Carbon Steel galvanized Other material combinations on request Product Types SF 11 Spiral wound gasket without any center ring for flanges with tongue and groove connection SF...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Pre-Loaded Packing Ring in Metal Casing Characteristics WDR-rings are ready-to-fit sealing elements for shafts and axles The wide sealing surface offers extra protection against early wear on the shaft and as well on the seal WDR rings are located in the housing with interference fit. The sealing effect is facilitated through the pre-loaded encapsulated packing. Different packing styles can be utilized depending on application Housing Standard: St 1403 galvanized Special: e.g. VA (1.4301) - CrNi Standard Insert P1P Budget to +200 °C Main application Crank and drive shafts Guiding shafts Axles, spindles and similar equipment Sealing against fluid leakage and dust penetration Protection for bearings and drive units Suitable for All Industries to seal against fluid loss or protect against dust and dirt ingress. Variant Special variantes: A 22 up to +450 °C for high temperature application S 7/G up to +250 °C for applications in abrasive environment etc. The packing insert...

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

As the leading provider of metal forming presses we are setting the standard worldwide. Our expertise in plant engineering and process technology is unique. This is because the individual performance features from the design to the startup of the equipment create a coherent and complete solution from a single source. Our hydraulic presses for metal forming are at home in cold and hot forming. From turbine disks for aircraft to pipeline pipes in the oil and gas industry to longitudinal beams in trucks: In our key industries of automotive, energy, rail and aerospace, we offer the right solution for every product. We supply not only the press, but also the associated process technology. Our range of services includes forging, thick sheet metal forming, raw forming, sheet metal forming and ring rolling. Our special systems for metal forming offer the perfect balance between the use of standard components and a custom-made design.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

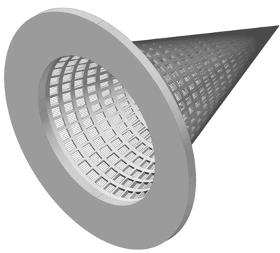

CHARACTERISTICS For clamp mounting into the pipeline Efficient protection of dirt-sensitive system components during commissioning Low differential pressure Easy installation and replacement Material Certificates DIN EN 10204/3.1 for Clamp Collar OPTIONS For DIN and ASME flange connections Design for low temperature down to -50 ° C Design pressure up to 100 bar Stainless steel construction Reverse flow direction GENERAL The starting screen VAS is used for commissioning and starting a system in order to clean gas from coarse soiling such as welding bead, scale, grease, etc. After starting, the starting screen can be removed from the pipeline. The design is carried out as a welding design. FUNCTION The starting screen VAS consists of a supporting basket made of perforated sheet metal with a welded clamping ring. These are galvanized after assembly. On the outside of the support basket a stainless steel wire mesh is welded.

Request for a quote

OPIS TECHNOLOGY GMBH

Germany

1970s inspired fixed-line push-button telephone with classic metal bell ringer The PushMeFon is a telephone in the classic shape if the 1970s. With its retro styling and modern colours it will easily attract the attention of friends and family, and because of the latest technology inside you can simply plug it in and use it. Have fun talking! Technical Specifications corded push-button phone modern colours version with classic metal bell (Sound sample) ring indicator light supports tone dialling Package includes Opis PushMeFon landline telephone telephone cable with interntional RJ11 plug telephone cable adapters for Germany, France, UK Dimensions length: 23 cm width: 22 cm height: 13 cm weight: 0.9 kg

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• Torque range: 4.000 - 70.000 Nm • 3-parted construction- easy to fit - variable in use • flange hub or conical ring hub • Shaft diameter: 60 - 220 mm • backlash free – exact torque transfer • high torsional stiffness - low moments of inertia • high tolerance of shaft displacements

Request for a quoteResults for

Metal ring - Import exportNumber of results

12 ProductsCountries

Company type