- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal oxides

Results for

Metal oxides - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Golden anodizing specifically refers to creating a layer of golden oxide on the metal surface through the anodizing process. Golden anodized surfaces have a beautiful, metallic gold hue. The color is not only aesthetically pleasing but also provides additional durability and corrosion resistance to the metal.Decorative Purposes: Golden anodizing is often used for decorative purposes, such as architectural elements, jewelry, and consumer electronics. Functional Uses: Beyond aesthetics, it also serves functional purposes, such as preventing galling of threaded components and creating dielectric films for electrolytic capacitors. golden anodizing combines both functionality and aesthetics, making it a popular choice for various applications. Whether you’re looking to enhance the appearance of a product or improve its durability, golden anodizing is a versatile process that delivers impressive results.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

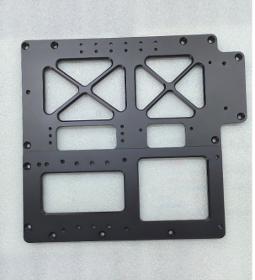

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

EEx’e’ certified electric duct air heater EEx e T2 – T6 ATEX The “LEH-Exe” type electric heaters comprise a range of certified EEx e air duct heaters, custom built to meet client specifications and suitable for use in zone 1 & 2 hazardous areas. The main applications are the heating of air in ventilation - / air conditioning or heat-recovery installations. Wide use areas are applications of the process - / environment-technology i.e. at the catalytic afterburning of exhaust fumes or drying ovens or in the plastic - / textile or paper industry. Through a variable construction concept, diverse use possibilities emerge. The application of highly compacted electrical heating elements with high purity compacted magnesium oxide powder sheathed metal tube and the direct heat transfer at the medium to be heated leads to an efficient realization of the electric energy to thermal energy. Special materials of acid constant rustproof steel stand for the heating of aggressive media by disposal. Alternatively, the heaters can be delivered also in the materials INCOLOY, INCONEL, HASTELLOY and MONEL. The duct heaters essentially consist of the following main-components: Duct with flat flanges Rod heating elements Temperature Sensors (Thermostat / Thermocouple / RTD) Electrical terminal box

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electric duct heater Electrical duct heater type “LEH-K” are intended for the heating of gaseous media. The main applications are the heating of air in ventilation - / air conditioning or heat-recovery installations. Wide use areas are applications of the process - / environment-technology i.e. at the catalytic afterburning of exhaust fumes or drying ovens or in the plastic - / textile or paper industry. Through a variable construction concept, diverse use possibilities emerge. The application of highly compacted electrical heating elements with high purity compacted magnesium oxide powder sheathed metal tube and the direct heat transfer at the medium to be heated leads to an efficient realization of the electric energy to thermal energy. Special materials of acid constant rustproof steel stand for the heating of aggressive media by disposal. Alternatively, the heaters can be delivered also in the materials INCOLOY, INCONEL, HASTELLOY and MONEL. The duct heaters essentially consist of the following main-components: Duct with flat flanges Rod heating elements Temperature Sensors (Thermostat / Thermocouple / RTD) Electrical terminal box

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electric Air heater Electrical air heater type “LEH-A” are intended for the heating of gaseous media. The main applications are the heating of air in ventilation - / air conditioning or heat-recovery installations. Wide use areas are applications of the process - / environment-technology i.e. at the catalytic afterburning of exhaust fumes or drying ovens or in the plastic - / textile or paper industry. Through a variable construction concept, diverse use possibilities emerge. The application of highly compacted electrical heating elements with high purity compacted magnesium oxide powder sheathed metal tube and the direct heat transfer at the medium to be heated leads to an efficient realization of the electric energy to thermal energy. Special materials of acid constant rustproof steel stand for the heating of aggressive media by disposal. Alternatively, the heaters can be delivered also in the materials INCOLOY, INCONEL, HASTELLOY and MONEL. The air heater essentially consist of the following main-components: Process flange Rod heating elements Temperature Sensors (Thermostat / Thermocouple / RTD) Electrical terminal box

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Electric duct heater Electrical duct heater type “LEH-R” are intended for the heating of gaseous media. The main applications are the heating of air in ventilation - / air conditioning or heat-recovery installations. Wide use areas are applications of the process - / environment-technology i.e. at the catalytic afterburning of exhaust fumes or drying ovens or in the plastic - / textile or paper industry. Through a variable construction concept, diverse use possibilities emerge. The application of highly compacted electrical heating elements with high purity compacted magnesium oxide powder sheathed metal tube and the direct heat transfer at the medium to be heated leads to an efficient realization of the electric energy to thermal energy. Special materials of acid constant rustproof steel stand for the heating of aggressive media by disposal. Alternatively, the heaters can be delivered also in the materials INCOLOY, INCONEL, HASTELLOY and MONEL. The duct heaters essentially consist of the following main-components: Duct with adapters to flanges DIN EN 1092 Rod heating elements Temperature Sensors (Thermostat / Thermocouple / RTD) Electrical terminal box

Request for a quote

HUGO BRENNENSTUHL GMBH & CO. KG

Germany

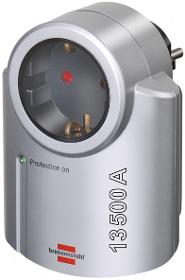

Efficient surge protection made from gas discharge tube and metal oxide varistors with thermal fuse. Protects electrical appliances against surges with a max. up to 13.500 A. Protects phase, neutral- and the protective earth. Indicator for the protective function. Max. loading of 16 A/3680 W. Childproof socket. In blister packaging. Nominal current: 16 A Colour: Silver/Black Plug-in system: DE

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The benefits of using aluminium in machine and plant construction are abundant: although aluminium is considered to be a light metal with a density of 2.6 to 2.8 g per cm³, which offers potential weight savings of up to 66% compared to steel and stainless steel, it still has exceptional strength considering these properties. However, the design and concept of steel constructions can often not be transferred one-to-one, due to the higher malleability and lower residual stress of aluminium components. An additional benefit is the aluminium's inherent resistance to corrosion: When exposed to oxygen, the light metal forms an oxide coating, which is immediately regenerated upon permeation. Standard processing methods, such as MIG, TIG and CMT welding can easily be used on aluminium without hesitation – particularly on substrates that are also made of aluminium. In some instances, they can be carried out more easily, more quickly and using simpler equipment, which results in further...

Request for a quote

PPS GMBH

Germany

The magnetic stripe is the classic feature of a Plastic card. The stripe is covered with a magnetic metallic oxide - it can be encoded and read. Magnetic stripes are cheap data carrier for universal use. The encoded data can be changed in contrary to a fix printed individual barcode. The price advantage in comparison to other data carrier such as Contact- or RFID chips and the variability of data makes the magnetic stripe a widely application in many fields. There are two different types of magnetic stripes. The resistance against deleting (coercitivity) makes the difference. The capacity is the same in both types. LoCo coercivity: 300 Oersted* colour: brown or black prone to magnetic perturbation HiCo coercitivity: 2750 Oersted* or 4000 Oersted* colour: black relatively resistant against magnetic perturbation *Oersted (Oe) is the unit for magnetic field strength Both types do have the same measures and are standardized acc. to DIN 7811. Standard Plastic cards with magnetic...

Results for

Metal oxides - Import exportNumber of results

10 ProductsCountries

Company type