- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- material containers

Results for

Material containers - Import export

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dissolving of a wide range of sealants and adhesives such as polyurethane residues, materials containing epoxies Elimination of oily and greasy soiling Removal of bitumen and tar splashes Dissolving of labels and adhesive strips Removal of paints on a PMMA and PU resin basis from metal surfaces Advantages and benefits Good infiltration of adhesive films allows easy removal of the residues from the surface Good washable with water after use Applicable to surfaces of metal, stainless steel, glass, wood, ceramics. Do not apply on sensitive materials such as PVC, PS or on painted surfaces Low effect on the climate and no negative influence on the ozone layer (ozone-depleting potential: ODP = 0) Free of surfactants, halogenated and aromatic solvents

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

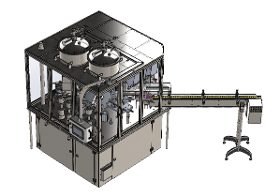

An automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five work stages that start with pulling the empty containers, then filling them, then placing the covers, then welding and taking out through the conveyor belt. It is suitable for high and medium production with a productivity of 3000 packages per hour.

Request for a quote

NISSHA EUROPE GMBH

Germany

Our biodegradable jars are ready for manufacturing in Germany and in Japan. We have two different mateial grades, 'Premium' and 'Universal'. 'Premium' material which contains visible wood chips adds natural and luxurious look to our customer's product., while 'Universal' material with smaller wood chip inside gives smooth texture and fits well with our customers' brand image. 4 different size jars(7ml, 9ml, 133ml and 200ml ) are currently available for dry and oily foods such as supplement and chocolate. 150ml jar is going to be availabel in 2022 Q1. <Feature> ・100 % plant-based material ・9 standard colour available ・Industrial compostable and free from microplastics (EN13432) ・Food Safety Material (Regulation (EU) 10/2011) ・Natural and luxurious look ・Custom designed product available upon request In additon, we can provide logo printing and liners for better sealing.

Request for a quote

NISSHA EUROPE GMBH

Germany

Our biodegradable jars are ready for manufacturing in Germany and in Japan. We have two different mateial grades, 'Premium' and 'Universal'. 'Premium' material which contains visible wood chips adds natural and luxurious look to our customer's product., while 'Universal' material with smaller wood chip inside gives smooth texture and fits well with our customers' brand image. 4 different size jars(7ml, 9ml, 133ml and 200ml ) are currently available for oily and powder cosmetics such as balm and shea butter oils. 150ml jar is going to be availabel in 2022 Q1. In addition, 60ml new jar just became available for water-based cosmetics. <Feature> ・100 % plant-based material ・9 standard colour available ・Industrial compostable and free from microplastics (EN13432) ・Natural and luxurious look ・Custom designed product available upon request In additon, we can provide logo printing and liners for better sealing.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

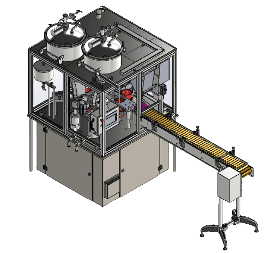

an automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five stages of work, starting with pulling the empty containers, then filling them, then placing the aluminum or nylon cover, then welding with cutting and taking out through the conveyor belt. It is suitable for medium production with a productivity of 1500 packages per hour.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

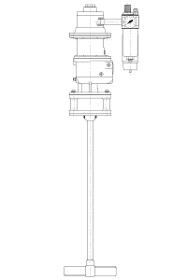

The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0.

Request for a quote

KAUP GMBH & CO KG

Germany

Forklift truck attachments, stationary equipment for material handling and container spreaders from KAUP are known for their ease of use. Because the user-oriented design makes it possible for it to fulfil its intended use for years. That notwithstanding, it is normal that even KAUP products are subject to more or less heavy wear, depending on use. That can lead to delays in normal operations and even to breakdowns. In order, however, to keep the downtime of an attachment, a stationary equipment for material handling or a container spreader as short as possible in this case, there is the qualified customer service from KAUP. Because, it doesn't matter whether it is replacement parts for an attachment, professional technicians for repair and maintenance, training for regular care or continual maintenance of the KAUP products: the more than 60 employees in customer service at KAUP are the professional contact for every user.

Request for a quote

SUPER-FILAMENT EINE MARKE DER ADDITIVE MATERIALS GMBH

Germany

We stock high-quality 3D printing filament for private and commercial customers or produce containers, colours or material according to your requirements. Our premium 3D printing filament from EU production offers you the highest quality for demanding projects. The wood filament consists of 100% organic material. The wood filament contains 40% real wood particles. Objects printed with this material have a structure similar to that of chipboard, for example. This wood filament offers a real wood look and feel. The printed parts can then be mechanically finished or painted.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

An alternative to conductive heat sealing is contact induction sealing, which is particularly suitable for sealing demanding container materials such as e.g. glass, metal or ceramic. An electromagnetic field is built up by a generator via an induction coil that is housed in the sealing head. The molecules of the aluminum foil are set in rotating vibrations, creating heat that is used for the sealing process. Our sealing machines PolySeal Vario PN and PolySeal Vario Twin as well as all fully automatic sealing systems can be equipped with induction technology.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

This Behringer's semi-automatic straight-cutting bandsaws combine the high-cutting output and simple handling which are utilized for economical processing of low piece numbers and one-off cuts. They feature easy handling that are precised in isolating the easy and difficult cuts. These machines are suitable in cutting pipes and all the materials which contain difficult machining properties and they can also provide semi-automatic variants that are recommended for the accurate positioning of a longer cut piece.

Request for a quote

STRONG MAGNETS GMBH

Germany

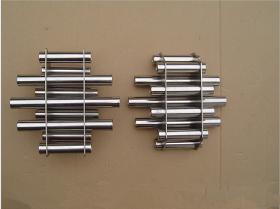

Scope of application Magnetic filter rod (magnetic rod) is mainly used to remove ferromagnetic impurities in powder, granular and liquid or slurry. It is widely used in ceramics, power, mining, plastics, chemical industry, rubber, pharmaceuticals, food, environmental protection, pigments, dyes, electronics, metallurgy and other industries. Working Principle The magnetic rod is made of high quality stainless steel pipe and high B value rare earth alloy NdFeB, and is made by special manufacturing method. The magnetic filter can be assembled on a fixed frame to form a magnetic filter. When the material containing iron passes through, it is attracted by the magnetic rod, and the material containing iron is firmly adsorbed on the wall of the magnetic rod. To ensure the integrity of equipment and product safety. Product features energyfree, pollutionfree, can be installed in any position on the production line with material contact, saving space, easy installation.

Request for a quote

BIO STROHHALME GMBH

Germany

The BIO-POT®-straws are 69 % bio-based on starch (potatoes) and fibers and 31% on minerals, calcium and magnesium. They are completely biodegradable and quickly compost in industrial composting plants. The plasticizer-free, mineral oil free thermoplastic material contains a high portion of biologically sourced and genetically unchanged raw materials. Thus, the BIO-POT®-straws make a decisive contribution towards reducing strain on the environment. Only usable for beverages up to 30 Grad C. Durability ca. 18-21 month in dry environment under propper storage conditions. The BIO-POT®-straws can be incinerated without residues and are also recyclable. Made in the EU, the raw material for the straw production originates from Germany. Available in the colors black and white - 500 pcs per bag as straight or flexible straw and in different diameters and lengths. Packed either in polybags or in the semi-transparent and also bio-degradable “Compost OK” bag.

Request for a quote

BAUER GMBH

Germany

can be stacked (3 units) Type BBG -sturdy steel construction made of smooth -steel sheeting Type BBK -sturdy construction made of smooth steel sheeting -with hinged inclined wall for easy loading p.e. with wheelbarrow -reinforced strutting on the rear side of the front flap -secure on both sides to close the front flap Type BBP -sturdy construction made of distortion-proof steel sheeting Accessories -cones for emptying via tilting traverse type BBT galvanized lid, lockable

Request for a quote

MIXACO MASCHINENBAU

Germany

MIXACO Container Mixer Vortex™ It is suitable for any industry where different recipes need to be mixed in quick succession, resulting in frequent mixer cleaning. As the transport container and mixer head are separate units, products can be conveyed to the next processing station without loss of time. The design of the MIXACO Vortex™ mixer, which was robust from the outset, is continuously being improved and updated. The system and its individual components are also configured for multi-level operation, with corresponding connectors to allow dust-free, airtight discharging of the transport container directly into extrusion, kneading, weighing and bagging machines. The MIXACO Vortex™ is more than simply a classic among container mixers; it also offers modern technology with numerous advantages for your in-house material logistics and work processes.

Request for a quote

MIXACO MASCHINENBAU

Germany

The MIXACO container mixer Multitool™ is ideal for the careful mixing of temperature-sensitive materials. An innovative mixing concept with new tools and a special process enables mixing without temperature increase. The MIXACO Multitool™ is a container mixer with numerous benefits for internal logistics and production workflows, as it can be seamlessly integrated in work processes. All Benefits at a Glance * Minimal product heating * Optimum homogenization * Adjustable comminution rate * No fusion or adhesion of material * Reduced cleaning time * User-friendly, ergonomically optimized cleaning in preconfigured cleaning position * Material transport in mixing container for greater logistical efficiency * High flexibility * Wide range of tool and motor combinations enable use in many different mixing tasks * Low energy consumption

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

The HELIO®MAT dryer station is part of the JETBOXX® system and features an independent JETBOXX® dryer with full functionality at each individual docking station. The material can be predried in removable drying containers at the dryer station. The drying container can be removed and brought to the processing machine if needed. It will be attached directly onto the feeding section there and the dried material can be processed. If the material should be kept dry on the machine, a JETBOXX® docking plate with dryer control are used in addition. HELIO®MAT is applicable for example as pre-drying station for quick material change, as dryer station for sampling batches, for batch drying for small quantities / sampling, for laboratory applications, or for cleanroom supply with hermetically sealed dry material containers. Material change without delay. No humidification. No cleaning issues.

Request for a quote

MIXACO MASCHINENBAU

Germany

By means of the moveable container with the mixed material, container with separate trolley, will be positioned in the tumbling mixer. The moveable container will be lifted by a pneumatic stamp. The trolley will be fixed in the tumbling mixer by means of a pneumatically actuated draw-in device. The head of the tumbling mixer formed as a container, fixed on the mixing head with four pneumatically operated clamping jaws including forklift pockets and discharge valve. The lifted container is locked to the tumbling head by means of pneumatically actuated locks. After fixing of the container at the tumbling head a SPS controlled tumbling process starts.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PERKUTE MASCHINENBAU GMBH

Germany

As the conveying machines are manufactured according to customers requirements they are easily integrated in the existing production layout. A variety of transportation systems and the possibility of integration allows for a very large application area; e.g. cleaning of massproduced goods, long materials, boxes, containers and pallets. The PERKUTE-system: economically - environmental – effektive Basic equipment Made of stainless steel Compact construction Simple operation User-friendly Easy maintenance Wide range of basic equipment Lateraly build-up tank, filter baskets incl. Temperature indicator for every region Low water level protection as protection against dry running Minimum operating cost because of tank insulation Maintenance hatch in the hoods

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

As the conveying machines are manufactured according to customers requirements they are easily integrated in the existing production layout. A variety of transportation systems and the possibility of integration allows for a very large application area; e.g. cleaning of massproduced goods, long materials, boxes, containers and pallets. The PERKUTE-system: economically - environmental – effektive Basic equipment Made of stainless steel Compact construction Simple operation User-friendly Easy maintenance Wide range of basic equipment Lateraly build-up tank, filter baskets incl. Temperature indicator for every region Low water level protection as protection against dry running Minimum operating cost because of tank insulation Maintenance hatch in the hoods

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Tabletop soap dispenser in chromeplated brass for counter mounting. Solid body in brass; visible surfaces highgloss chromeplated. Nondrip soap pump with 500 ml soap container in plastics and pressure valve in brass. Designed for standard liquid soaps. Refillable from above by unscrewing the top part. Delivery includes fixing material. Dimensions (with container) 65 x 456 x 160 mm Design height 208 mm Outlet height 198 mm Projection 111 mm

Request for a quote

ERNST WAGNER GMBH & CO. KG

Germany

Tabletop soap dispenser in chromeplated brass for counter mounting. Solid body in brass; visible surfaces highgloss chromeplated. Nondrip soap pump with 500 ml soap container in plastics and pressure valve in brass. Designed for standard liquid soaps. Refillable from above by unscrewing the top part. Delivery includes fixing material. Dimensions (with container) 65 x 310 x 130 mm Design height 62 mm Outlet height 37 mm Projection 74 mm

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

An alternative to conductive heat sealing is contact induction sealing, which is particularly suitable for sealing demanding container materials such as e.g. glass, metal or ceramic. An electromagnetic field is built up by a generator via an induction coil that is housed in the sealing head. The molecules of the aluminum foil are set in rotating vibrations, creating heat that is used for the sealing process. Our sealing machines PolySeal Vario PN and PolySeal Vario Twin as well as all fully automatic sealing systems can be equipped with induction technology.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quoteResults for

Material containers - Import exportNumber of results

123 ProductsCountries

Company type

Category

- Pipe and tube fittings - ferrous metal (97)

- Automation - systems and equipment (2)

- Gas fittings (2)

- Towel and soap dispensers (2)

- Bottles and jars, plastic (1)

- Building materials, manufacture - machinery and equipment (1)

- Cement-making - machinery and equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Containers, metal (1)

- Cosmetics (1)

- Forklift trucks (1)

- Magnets (1)

- Models for the building industry (1)

- Oilseed crops (1)

- Package stamping machinery (1)

- Packing and packaging - machinery and equipment (1)

- Plastics - industrial machinery and equipment (1)

- Plastics - machines and material for industry (1)

- Sawing machine tools (1)

- Silicones (1)