- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- marking system

Results for

Marking system - Import export

PAUL LEIBINGER GMBH & CO. KG

Germany

The JET2neoS was developed specifically for smaller fonts and higher production speeds. The JET2neoS is equipped with all the advantages of the JET2neo series but features a smaller 60µ nozzle. This allows the CIJ printer to print considerably faster and finer than the JET2neo. The JET2neoS is tried-and-tested in the industrial marking of extrusion parts, food and drink packaging and plastics, among other uses. With the automatic nozzle seal "Sealtronic" in the JET2neoS, LEIBINGER can guarantee that the ink does not dry, even after long-term shut-downs. When production stops, the gutter and the nozzle form an airtight circuit: No ink may leak from the circulation and no air can come in. Even after long downtimes LEIBINGER inkjet printers are ready to print within a minute – without cleaning cycles.

Request for a quote

PAUL LEIBINGER GMBH & CO. KG

Germany

The high-performance LEIBINGER JET2neo inkjet printer is the ideal marking system for all daily tasks when marking different materials, products and surfaces in industry. High-quality materials, sophisticated technologies and the best production processes guarantee very long service life and absolute reliability. The JET2neo prints fixed and variable data such as text, barcodes, expiration dates, lot/batch numbers, 2-D codes, shift codes or graphics without contact and during ongoing production with fast-drying inks. With the automatic nozzle seal "Sealtronic" in the JET2neo, LEIBINGER can guarantee that the ink does not dry, even after long-term shut-downs. LEIBINGER inkjet printers are ready to print within a minute – without cleaning cycles. The JET2neo is the perfect marking system for all of your daily tasks. The JET3up inkjet printer series is available for special requirements.

Request for a quote

PAUL LEIBINGER GMBH & CO. KG

Germany

The JET3up EP is a special industrial printer for marking and coding eggs and egg packages. It is compatible with egg sorting and packaging machines from the leading manufacturer Moba Group. The cooperation between LEIBINGER and the Moba Group makes it possible to conveniently integrate the continuous inkjet printer into their egg sorting machines. That simplifies the process of marking and coding eggs and egg cartons many times over.

Request for a quote

PAUL LEIBINGER GMBH & CO. KG

Germany

The LEIBINGER JET3up is an extra flexible inkjet printer and is therefore suitable for conventional as well as for complex demands in product marking and coding. Over 800 practical functions, numerous options, a wide range of equipment and expanded computer software solutions are available for the users. Possible are up to 5-line print jobs and a print quality up to 32 drop resolution. With the automatic nozzle seal "Sealtronic" in the JET3up, LEIBINGER can guarantee that the ink does not dry, even after long-term shut-downs. When production stops, the gutter and the nozzle form an airtight circuit: No ink may leak from the circulation and no air can come in. Thus, the ink remains liquid as in a closed can of lacquer and the inkjet printer is always ready for use. Even after long downtimes LEIBINGER inkjet printers are ready to print within a minute – without cleaning cycles.

Request for a quote

PAUL LEIBINGER GMBH & CO. KG

Germany

The LEIBINGER JET2neoEP continuous inkjet printer is the easy and reliable marking and coding solution for standard applications in the egg industry. The JET2neoEP reliably marks and codes eggs and egg cartons within the egg sorting machines. Compatible with egg sorting and packaging machines from the leading manufacturer Moba Group » Easy and complete integration with plug-and-play connection » Approved installation kits for Moba and Diamond egg sorting machines » Automatic creation and modification of print jobs using the egg sorting machine‘s control system or a manual solution at the printer » Accurate printing for each egg » Highly accurate printing on the egg or egg carton » Central print data management » Best before date and other variable data are updated automatically » Option to mark and code the packaging before or after filling it » Marking and coding imprint can be changed conveniently in the event of multiple customers

Request for a quote

PAUL LEIBINGER GMBH & CO. KG

Germany

The LEIBINGER JET2neoD industrial inkjet printer is the perfect marking system for standard applications in production environments with small amounts of dust. The continuous inkjet printer is suitable for use in somewhat dusty production environments and in environments with very small particles, such as sawdust. In addition to all benefits and functions of the LEIBINGER JET2neo series, the JET2neoD is equipped with three more features that allow it to be used in dusty production environments. 1. The closed back panel prevents dust and particles from getting into the printer. 2. The active housing ventilation guarantees that the printer will be ventilated and protects the electronics from dust. 3. The head ventilation generates a small amount of positive air pressure in the printhead. Even when there is dust present right on the marking position and when printing from below, the printhead always remains dust-free.

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

Industrial inkjet printers enable flexible, contactless and cost-effective marking of packaging, goods and pallets. They are suitable for various substrates and applications without disrupting the production process. Inkjet printers create the printed image by selectively releasing ink droplets and offer easy maintenance, a large distance between the print head and substrate, variable print content and flexible integration. Important selection criteria include production environment, size of print image, resolution, surface texture of the substrate, space and line speed. Matthews Marking Systems uses various inkjet printing processes and offers inks for porous and non-porous surfaces. The printers are suitable for many materials, including wood, plastic, metal, pallets, tires and corrugated cardboard. They can be adapted to individual space requirements and offer solutions for both dusty and clean production environments.

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

The piezo inkjet printer (PIJ) is an inkjet printer with a contactless printing process. This industrial marking and coding system is ideal for printing high-resolution text, graphics, barcodes and more on a variety of products and packaging materials. Compared to other brands, our piezo inkjet printer uses up to 35% less ink. The printheads are mainly used in industrial areas for marking secondary packaging (e.g. cartons, corrugated cardboard boxes and tray packs). However, our piezo inkjet printers also achieve excellent legibility on porous materials. By combining several print heads, it is possible to apply large-area markings and graphics. This ensures that your product information, logos and graphics are always presented in high quality and clear legibility. By replacing labeling systems or pre-printed cartons with a PIJ printer, you can reduce your production costs. Discover the outstanding print quality of our piezo inkjet printers and arrange a no-obligation test print.

Request for a quote

REA ELEKTRONIK GMBH

Germany

CO2 laser marking systems are part of the gas laser group: the laser beam is generated in an enclosed laser tube which is filled with carbon dioxide. The REA JET CL is suitable for the marking of packaging, glass, wood, plastics, PVC, anodized aluminum, the color removal on surfaces as well as direct marking of foods. In the creation of texts, graphics and characters there is complete freedom of design. Applications — Marking of glass, wood, rubber, engraving and color change marking of plastics (automotive, medicine, consumer goods) — Coding of cardboard boxes and outer packaging (e.g. in the pharmaceutical, cosmetic and food sectors) — Coated substrates (e.g. anodized aluminum) — Direct marking of foodstuffs — Laser color change marking — Color mirror engraving

Request for a quote

REA ELEKTRONIK GMBH

Germany

The REA JET One Dot Systems (EDS) are particularly well suited to very fine dot and line markings. The dot size is configured by selecting the nozzle size and by varying the material pressure, and the stepless setting on the controller. Applications — for quality assurance you can mark products with a dot to be recognized as either good or bad (use automatic camera recognition) — colored line marking for pipes, profiles and endlessly manufactured products (e.g. extruded goods) — applying oils, separating agents, soaps or process water — welded seam marking in the manufacturing of metal profiles — applying fragrances to cosmetic samples

Request for a quote

REA ELEKTRONIK GMBH

Germany

Fiber laser marking systems are part of the solid-state laser group. The laser beam is created in a diode-activated optical fiber. The REA JET FL is suitable for permanent the marking of metal and plastic surfaces. The marking with codes, texts, numbers or logos may even take place on oily, corroded or above 1000°C hot surfaces. Applications — engraving and annealing metals — color inscription of untreated and with additives doped plastics — day and night design — coated substrates

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Labelling systems can be integrated, whether it is laser, needle or inkjet, to mark and identify the tubes. Other options that can be integrated are welding seam detection, length control or measurement of processed tubes. The corresponding sensor and camera technology can be implemented for the specific product. The following step can be carried out without any problems, whether it is cutting, punching, deburring of holes or seal testing with external systems. Smart data evaluation All the systems can be equipped with different control and IPC panels. Interfaces to data caption systems for consumption and operation make the digitalization and evaluation of the data. Marking system, Welding seam detection, Camera control system, Internal and external cleaning processes, Cleaning and suction, Hole punching, Deburring – chamfering

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

Matthews Marking Systems offers specialized inkjet and software solutions for the metal industry which can handle high temperatures, oily or dusty surfaces and changing material compositions. The MPERIA® V-Series enables clear marking on various materials and can be integrated into production systems. It is particularly suitable for machine builders and OEMs, with benefits such as specialty inks, low maintenance, high availability, robust design and flexible printhead mounting. Matthews' specialty inks are highly adhesive, fast drying and temperature resistant, ideal for aerospace and marine applications. The V-Series printheads are durable, low maintenance and enable automated cleaning processes. Large ink containers reduce maintenance cycles. The MPERIA® V-Series integrates into existing production lines and enables printing from different angles. Central control is provided by the MPERIA® universal controller, also in a version for harsh environments.

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

Optimize your package coding with our advanced 10W and 30W laser marking systems, specifically designed for marking and coding on consumer packaged goods. These cutting-edge lasers offer unparalleled precision, speed, and durability, making them the ideal choice for a wide range of applications. Whether you need to mark 2D barcodes, batch numbers, expiration dates, or crystal-clear alphanumeric characters, our laser solutions ensure clear, permanent, and high-quality results. 10W Laser Marking System Perfect for Light to Medium Marking Requirements Our 10W laser marking system is an excellent choice for light to medium marking needs. It delivers precise, permanent marks on various materials, ensuring that your product information is always clear and legible.

Request for a quote

ETIKETTENDRUCK FÖRSTER GMBH & CO.KG

Germany

We have been designing and producing UL labels for well-known industrial companies since 1990. The requirements and regulations are very complex and may require a detailed consultation in order to explain the UL-compliant marking and the different application programs. The UL certification of an end product by an OEM (Original Equipment Manufacturer) refers to every single component of the product. A label is such a component whose requirements are regulated in the UL 969 “Standard for Marking & Labeling Systems”.

Request for a quote

ETIKETTENDRUCK FÖRSTER GMBH & CO.KG

Germany

We have been designing and producing UL labels for well-known industrial companies since 1990. The requirements and regulations are very complex and may require a detailed consultation in order to explain the UL-compliant marking and the different application programs. The UL certification of an end product by an OEM (Original Equipment Manufacturer) refers to every single component of the product. A label is such a component whose requirements are regulated in the UL 969 “Standard for Marking & Labeling Systems”.

Request for a quote

ETIKETTENDRUCK FÖRSTER GMBH & CO.KG

Germany

We have been designing and producing UL labels for well-known industrial companies since 1990. The requirements and regulations are very complex and may require a detailed consultation in order to explain the UL-compliant marking and the different application programs. The UL certification of an end product by an OEM (Original Equipment Manufacturer) refers to every single component of the product. A label is such a component whose requirements are regulated in the UL 969 “Standard for Marking & Labeling Systems”.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ETIKETTENDRUCK FÖRSTER GMBH & CO.KG

Germany

We have been designing and producing UL labels for well-known industrial companies since 1990. The requirements and regulations are very complex and may require a detailed consultation in order to explain the UL-compliant marking and the different application programs. The UL certification of an end product by an OEM (Original Equipment Manufacturer) refers to every single component of the product. A label is such a component whose requirements are regulated in the UL 969 “Standard for Marking & Labeling Systems”.

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

Experience the pinnacle of marking and coding efficiency with the MPERIA Controller. Seamlessly switch messages in seconds, enhance mark quality, and centralize coding control on your production lines regardless of equipment manufacturer. With over 170 years of expertise, we ensure ongoing support, making us your reliable partner today and beyond. Legacy Controller Challenges Companies grappling with outdated, inflexible marking systems face significant challenges in streamlining their product, case, or pallet marking processes. These systems are difficult to use, lacking automation features, and hinder seamless integration into existing production environments. The absence of user-friendly interfaces and manual code changeovers lead to increased errors, bottlenecks, and inefficient operations, resulting in unnecessary labor hours and costly recalls. There is a pressing need for an easier-to-use, automated marking solution that enables efficient integration, improves

Request for a quote

ETIKETTENDRUCK FÖRSTER GMBH & CO.KG

Germany

We have been designing and producing UL labels for well-known industrial companies since 1990. The requirements and regulations are very complex and may require a detailed consultation in order to explain the UL-compliant marking and the different application programs. The UL certification of an end product by an OEM (Original Equipment Manufacturer) refers to every single component of the product. A label is such a component whose requirements are regulated in the UL 969 “Standard for Marking & Labeling Systems”.

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

The Matthews’ 10 watt and 30 watt C02 laser coding system permanently marks coated paper, plastics, rubber extrusion, and glass—making it ideal for a variety of industries. An affordable alternative to small character inkjet technologies, it cleanly marks alphanumeric text, date and time codes, serial numbers, barcodes, 2D codes and graphics.

Request for a quote

EUROLASER GMBH

Germany

An increase in productivity thanks to loading and unloading during the cutting process Workpiece removal during the cutting process at the collecting table possible The material feed is stretching-free Accurate placement of the workpiece through automatic edge control with the Feeding Unit Optional camera recognition system for automated processing Optional marking systems (e. g. Ink Marker) Processing of very large formats by edgeless continuation of cuts possible.

Request for a quote

U.I. LAPP GMBH

Germany

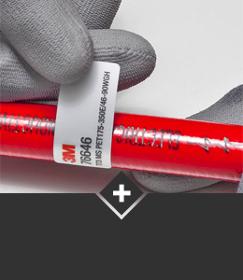

These sophisticated systems facilitate durable cable marking and ensure everything is clear and quick to identify. From simple inscriptions, to labelling and marking solutions for manual marking right through to FLEXIMARK® software for electronic recognition, this range can meet your every need. Benefits: — flexible and easy labeling — materials suitable for industry - ideal for harsh environments (high resistance to UV light, extreme temperatures, chemicals and abrasion) — manual and digital labeling solutions — customized printed markers — FLEXIMARK® software package with many layout templates and helpful functions for label creation (e.g. data import, barcode generation and easy insertion of images, logos and symbols)

Request for a quote

REA ELEKTRONIK GMBH

Germany

Ready for world wide use — Full Unicode support: all global languages can be printed for companies with international customers — Support of all True Type Fonts (TTFs): maximum design flexibility for your print — XML-based data structure and communication protocol: globally used standard for data compatibility — Sturdy and high-quality stainless-steel casing designed for daily work in rough industry environments — 24V power supply: for direct integration into machines and systems

Request for a quote

REA ELEKTRONIK GMBH

Germany

REA JET offers various ink and primer supplies - the right solution for every customer requirement. Always good to go - industry suitable ink and primer supply units — Highest chemical resistance — Best mixing performance for inks and primers — Avoidance of sedimentation — Greater range through higher filling capacity — Flushing function optionally available — Automatic or manual operation — Comprehensive accessories — Over 500 inks and primers

Request for a quote

REA ELEKTRONIK GMBH

Germany

The REA JET HR pro OEM is especially developed for a fully integrated installation in machines and systems. With the smallest dimensions in its class, the REA JET HR pro OEM controller fits into any type of machine and control cabinet. The HR pro OEM accommodates connection of up to 4 print heads, and its extremely high-performance processor is powerful enough to meet future coding and marking demands.The HR pro OEM is the first choice for rapid serialization applications and complete machine integrations. Applications — Short setup times, a flexible number of webs and zero-maintenance — ideal suited for late stage customization — Promotion codes on the back of paper lables — Batch number on give-away — Registration number on the inner surface of food packaging — Voucher codes on beverage bottle lables

Request for a quote

REA ELEKTRONIK GMBH

Germany

Coding, marking, pre-treatment in rough industrial environments. Print heads without compromises. The next generation is ready to take over. Speed potential pushed to another level, wear and tear significantly reduced. Print head brain work which pays off for our customers For improving our most legendary sturdy REA JET DOD large character print heads further on, we have been driven by two decisive customer needs: — Duplication of speed potential to up to 600 m/min — Multiplication of their durability by lowering wear and tear 7 nozzles = 5-27 mm 16 nozzles = 5-67 mm 32 nozzles = 5-140 mm

Request for a quote

REA ELEKTRONIK GMBH

Germany

The latest generation of REA JET GK 2.0 high-resolution coding and marking systems using piezo technology is suitable for direct, high-contrast coding and marking on absorbent and porous surfaces, such as wood, cardboard and paper, with a variable print height of up to 100 mm. Applications: — Porous and absorbent surfaces: paper, cardboard boxes, wood, textiles, fleeces, building materials, polystyrene, grinding wheels etc. — Variable print data such as date, time, counter, shift code or database content — Alphanumeric texts, barcodes, data matrix codes, logos, warning notes — Coding and marking of packaging — IPPC coding and marking on pallet blocks — EPAL coding and marking of pallets — CE marking on wood — Marking of paper sacks — All-round coding and marking of fiber drums — Marking of OSB panels with logo — Coding and marking of pallet boxes — Marking of gypsum boards or board stacks with large logos — Serialization and track & trace applications

Request for a quote

REA ELEKTRONIK GMBH

Germany

The REA JET SC enables contact free printing of 1 to 8-line texts, dates, barcodes, Data Matrix codes and logos in high resolution, and with print heights up to 12 mm. The robust and stainless steel housing with IP54 protection class and the intuitive operation make this coding and marking solution suitable for smooth surfaces like foils, laminates and a very wide assortment of plastics and metals. Applications — Printing of variable data such as counter, date, time, shift code, best before date date, etc. — Serialized data for traceability — Bidirectional printing — Alphanumeric texts, barcodes, 2D codes — Ideally suited for smooth surfaces thanks to short drying time — Ideal even with larger distance to product surface — Suitable for high production and marking speeds

Request for a quoteResults for

Marking system - Import exportNumber of results

46 ProductsCountries

Company type

Category

- Marking machines (11)

- Electric and electronic components - machines for manufacturing (8)

- Marking - diverse products (6)

- Automation - systems and equipment (6)

- Seals and packing material (6)

- Laser - cutting and welding machines (3)

- Printers - computer (3)

- Bar codes - printing machines (2)

- Metal engraving - machine tools (1)

- Marking and labelling machinery (1)

- Automatic piloting equipment (1)

- Embossing machine tools (1)

- Inks (1)

- Laser apparatus and instruments (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Pipes and tubes - ferrous metal (1)

- Plasma cutting machines (1)