- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- manufacturer metal

Results for

Manufacturer metal - Import export

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

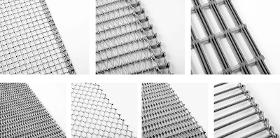

The Dutch Lesjöfors company Tribelt specializes in developing and manufacturing metal conveyor belts. For more than 70 years, the company has solved problems for customers in many different fields across Europe. We also manufacture sprockets, customized for the design and in the number your application require, its’ tension forces and surrounding environment.

Request for a quote

ZIMMER GMBH KUNSTSTOFFTECHNIK

Germany

THE BENEFITS OF TWO WORLDS Series components made of metal with complex shapes are usually very time-consuming and expensive to put into production -- but luckily there is now a superior alternative for these kinds of demanding workpieces in the form of MIM technology from Zimmer Group! The MIM process allows us to manufacture metal parts of almost any shape using an injection molding process, as easily as though it were plastic! This process lets us elegantly combine the geometrical freedom of plastic injection molding with the outstanding rigidity and wear characteristics of metals. The result is a thoroughly impressive technology for manufacturing metallic series production components with complex shapes -- and at very attractive prices, too!

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We offer customized die-cast parts, stamped parts, deep-drawn parts, turned parts, milled parts and contact springs, both as small-precision and large parts. Partial or complete plastic and rubber injection molding of metal parts is also part of our portfolio. The manufactured metal parts can be completed with sealing elements, threaded inserts and bearing bushes. We also offer processes for cold pressing, as well as cost-effective surface finishing. We accompany our customers throughout the entire project process and organize the tool and sample production as well as the production (including surface finishing) and optionally also the assembly of the series parts.

Request for a quote

FRIGORTEC GMBH

Germany

The POWDRYER™ PD08 metal powder dryer is used to dry inorganic metal powder for the complex additive manufacturing (3D printing) process. It corrects the manufacturer’s fluctuating metal powder qualities, thus optimizing the metal powder’s flowability. It also reduces the number of air inclusions in finished workpieces. Significantly higher material densities are the result. Fields of application > Particularly for metal printing products where maximum strength is required > For the printing of alloys of aluminium, titanium, tool steel, etc. > Special tools for the metal-processing industry, machine and system engineering, prototype development, and more > Aviation, aerospace, and automotive industries, plus medical and dental technology

Request for a quote

REA ELEKTRONIK GMBH

Germany

The REA JET One Dot Systems (EDS) are particularly well suited to very fine dot and line markings. The dot size is configured by selecting the nozzle size and by varying the material pressure, and the stepless setting on the controller. Applications — for quality assurance you can mark products with a dot to be recognized as either good or bad (use automatic camera recognition) — colored line marking for pipes, profiles and endlessly manufactured products (e.g. extruded goods) — applying oils, separating agents, soaps or process water — welded seam marking in the manufacturing of metal profiles — applying fragrances to cosmetic samples

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MERA BELLOWS C/O ANSCHÜTZ VERWALTUNGS GMBH

Germany

Deep-drawn tubes from stainless steels (with a closed side or open) Deep-drawn tubes from non-ferrous metals as bronze, brass,... Seamless sleeves made with stamping processes Ultra thin-walled tubing in Beryllium copper or other special alloys Annealing services in vacuum furnaces Washing technologies for soap and oil The precision tubing is needed at Mera Bellows to manufacture seamless metal bellows.

Request for a quote

EPLUS3D TECH GMBH

Germany

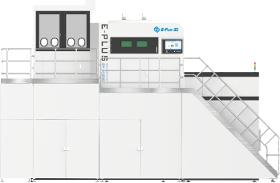

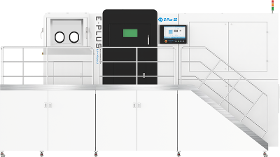

With Eplus3D MPBF™(Metal Powder Bed Fusion) technology, EP-M150 can professionally print complex 3D geometry data into high-performance metal 3D parts which are suitable for batch manufacturing of dental parts medical implants and material research centers to develop various metal powders with its open parameter platform.

Request for a quote

EPLUS3D TECH GMBH

Germany

Using MPBF (Metal Powder Bed Fusion) technology, the EP-M1250 is using a 1258 x 1258 x 1350 mm3 build envelope and nine laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase. The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Maraging Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is suitable for the direct manufacturing of largesize, high-precision and high-performance parts in the aerospace, aviation, automotive and machinery industry.

Request for a quote

EPLUS3D TECH GMBH

Germany

EP-M150Pro adopts patented MPBF™(Metal Powder Bed Fusion)to produce high performance, high accuracy and high details parts at large scale. The machine is capable of optional single/dual laser system, and 200/500W laser source for different production requirements. The available materials are Aluminum alloy, Titanium alloy, Inconel alloy, Maraging steel, Stainless steel, CoCr, Copper alloy and so on.

Request for a quote

EPLUS3D TECH GMBH

Germany

With a building chamber size of 455*455*500mm Eplus3D Introduces EP-M450 to the successfulline of MPBF™ 3D printers. The complete open systemmakes EP-M450 a very powerful tool for large scaleproduction for our customer to access different metal powders like titanium, aluminum, nickel alloys and stainless steel, etc. EP-M450 is aiming to output the large parts with its high performance and high accuracy.

Request for a quote

EPLUS3D TECH GMBH

Germany

Using MPBF (Metal Powder Bed Fusion) technology, the EP-M650 is using a 655x655x800mm3 build envelope and quad laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase. The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Maraging Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is suitable for the direct manufacturing of large-size, high-precision and high-performance parts in the aerospace, aviation, automotive and defense industry.

Request for a quoteResults for

Manufacturer metal - Import exportNumber of results

12 ProductsCountries

Company type