- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machining of plastic

Results for

Machining of plastic - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is a plastic cavity for CNC milling.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

washer, CNC turning parts,machined mechanical parts

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The accessories of panel.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Accessories used for furniture fitting parts,connector parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts used in Surfboard accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is a plactic cover,used for machine accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC plastic turning machining,mainly use for very precise mechanical parts.

Request for a quote

CRYOSNOW GMBH

Germany

• Heats up the compressed air up to 100 °C (212 °F) • Total avoidance of condensation • Simple and accurate temperature control • Easy to fix on control unit • Also suitable for dry ice blasting machines with CO2 pellets • For the cleaning of switch cabinets, thin metal sheets, electronic components

Request for a quote

MESUTRONIC GMBH

Germany

- detects and separates any type of metal, loose or encapsulated - flexible integration into existing conveying systems independent of direction, quick and cost-effective -easy to operate - high-precision metal detection, extremely reliable - uncompromising safety, thanks to mesuSafetyPack

Request for a quote

MESUTRONIC GMBH

Germany

metal separator was developed for the examination of plastic granulates, ground material and powders for metallic foreign bodies. It is used in the injection molding and extrusion areas for slow-flowing material columns. Both the detector and the ejection unit have been specially developed for this area of use. This results in top performance data for precision, operating reliability and ease of cleaning. Failsafe storage of all system parameters Digital signal processing for best detection Process- and condition monitoring Standardised system for a wide area of use Robust construction for maximum lifetime Highest precision in long-term operation Fast ejector for minimized material loss Dismantle without tools All components are easily accessible

Request for a quote

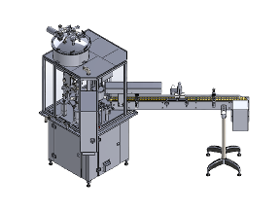

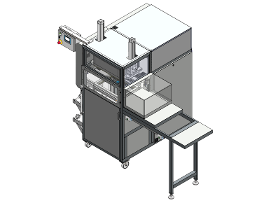

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

A full automatic packaging machine that fills in plastic containers and thermally welds them. It consists of five work stages that start with pulling the empty containers, then packing, then coverings, then welding and taking out. Suitable for medium products, with a production capacity of 1500 packages per hour.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of slow-running rolling and friction bearings, rollers, transport chains or sliding surfaces on kiln trolleys, bakery machines, drying tunnels, foundry machines, boiler firing systems, plastics processing machines for welding and soldering machines etc. Advantages and benefits Highly effective due to optimum temperature-stable silicone grease formula Excellently suited for grease lubricating points subject to high-temperature loading Broad range of uses outside normal grease performance areas

Request for a quote

A.E.T. KUNSTSTOFFE GMBH

Germany

"very strong adhesion to the sub-material high resistance to UV rays toxicologically harmless with normal use Vibration-inhibiting when used in the machine area Millions of people hold plastic products in their hands every day without being aware of this fact. Regardless of whether they are used on sports equipment, medical equipment or work equipment: What is certain is that the pleasant haptic impression - the ""experience of access"" - is an important purchase criterion for the buyer, along with design and functionality. "

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Incremental rotation sensors are used wherever displacement, positions or speeds have to be measured accurately. They are therefore important interfaces between the mechanical and electronic parts of a machine. Mechanically robust, electrically reliable and resistant to extreme ambient conditions; these are the outstanding properties offered by this sensor. Typical applications include —Machine tools —Wood and plastic machining —Textile machines —Lifts —Door systems —Paper machines —Drive equipment —Assembly and handling equipment —Packaging machines —Scales —Test machines —Conveying equipment —Doors and gates Specific characteristics —Degree of protection IP65, all-around —Robust —High resistance to interference —Rotary speed sensor: 60 pulses/turn (standard) —Angular displacement sensor: up to 3600 pulses/turn —Detection of rotation direction (channels A and B) —Reference pulse (channel N) —Special versions on request

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent at foundry operations injection moulding, blowing and extruding processes of plastics and elastomer Avoids the sticking of e.g. adhesives and sealing excess or water wetting Sliding agent against noisy rubbing of plastics, elastomers and metals together or against each other Lubrication of cutting edges in the paper, cardboard, veneer layer and textile processing machines For easy retracting of plastic and rubber profiles, e.g. in the door and window production Advantages and benefits High efficiency because of excellent netting of the surface and building of extremely thin lubricating films Separating effect with antistatic properties Manifold applications for permanent lubrication, protection, maintaining and impregnation Neutral behaviour against plastic and elastomers Resistant against water and atmospheric influences

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent at foundry operations injection moulding, blowing and extruding processes of plastics and elastomer Avoids the sticking of e.g. adhesives and sealing excess or water wetting Sliding agent against noisy rubbing of plastics, elastomers and metals together or against each other Lubrication of cutting edges in the paper, cardboard, veneer layer and textile processing machines For easy retracting of plastic and rubber profiles, e.g. in the door and window production Advantages and benefits High efficiency because of excellent netting of the surface and building of extremely thin lubricating films Separating effect with antistatic properties Manifold applications for permanent lubrication, protection, maintaining and impregnation Neutral behaviour against plastic and elastomers Resistant against water and atmospheric influences

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent at foundry operations injection moulding, blowing and extruding processes of plastics and elastomer Avoids the sticking of e.g. adhesives and sealing excess or water wetting Sliding agent against noisy rubbing of plastics, elastomers and metals together or against each other Lubrication of cutting edges in the paper, cardboard, veneer layer and textile processing machines For easy retracting of plastic and rubber profiles, e.g. in the door and window production Advantages and benefits High efficiency because of excellent netting of the surface and building of extremely thin lubricating films Separating effect with antistatic properties Manifold applications for permanent lubrication, protection, maintaining and impregnation Neutral behaviour against plastic and elastomers Resistant against water and atmospheric influences NSF H1-registered

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent at foundry operations injection moulding, blowing and extruding processes of plastics and elastomer Avoids the sticking of e.g. adhesives and sealing excess or water wetting Sliding agent against noisy rubbing of plastics, elastomers and metals together or against each other Lubrication of cutting edges in the paper, cardboard, veneer layer and textile processing machines For easy retracting of plastic and rubber profiles, e.g. in the door and window production Advantages and benefits High efficiency because of excellent netting of the surface and building of extremely thin lubricating films Separating effect with antistatic properties Manifold applications for permanent lubrication, protection, maintaining and impregnation Neutral behaviour against plastic and elastomers Resistant against water and atmospheric influences

Request for a quote

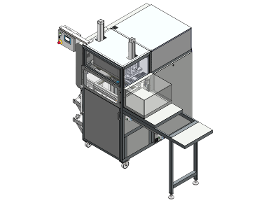

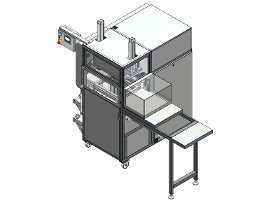

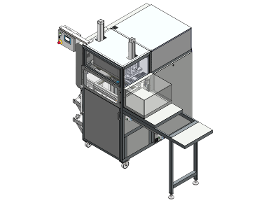

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 1800 is a fully automated foil application and sealing machine, suitable for plastic, tin or glass containers. mobile base frame feed conveyor with feed control synchronised star wheel stand with receptacles for the containers as form parts adjustable outer ring for guiding containers through the machine sequence foil magazine for stackable pre-cut Ballerstaedt seals pneumatically driven foil dispenser with a precise, maintenance free 180° reverse gear for removing the seals from the magazine, applying them to the sealing edge and fixing them with a pre-sealer sealing station for closing the containers with regulation of the sealing temperature, pressure and time for optimal setting of the seal parameters, conductive, optional also inductive exit conveyor for the containers central height adjustment of the magazine plate to adjust it to the respective container height all-over protective coating control panel with electrical supply unit

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling machine for liquid through to viscous products, e.g. ketchup and mayonnaise Object carrier mode e.g. for plastic bottles Machine performance: 10 cycles/min. max. 80 bottles/min. max. 4 800 bottles/h Special features: 8 dosing pumps Immersed filling by programmable fill cams Fully-automatic cleaning

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Compact filling and closing machine for cosmetic products 1-lane machine Direct processing of plastic jars, tins and glasses Machine performance: max. 60 jars/min. Special features: 1 dosing pump with motorised adjustment from 0-500 ml Rotating sealing system for glass jars Integrated screw-top machine with torque shut-off via servo-drive Fully-automatic cleaning of filling machine (CIP/SIP) Film applicator station Rotary station at the filling station (swirl effect)

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

AIR- AND WATER COOLED COLD WATER UNITS gwk chillers in the sklc series are air-cooled compact cold water units with integrated condenser gwk chillers in the skw series are water-cooled compact cold water units cooled with external cooling water These chillers are equipped with screw condensers; the power regulation of the capacity to be dissipated is continuous. Water-cooled cold water units in the skw series with low coolant content can be operated very efficiently and are preferably used when the available cooling water from gwk cooling towers, gwk free cooler systems or customer-provided supplies has a higher temperature level than required for the production process but is available inexpensively..

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

Whenever the process requires high temperatures and the advantages of water as heat carrier (best heat conductivity properties, inexpensive, low viscosity) are to be used, this construction series is the best solution. Absolute reliability, high regulating accuracy, easy operation and a favorable price /performance ratio: apart from the versatile performance features a modern temperature controller has to fulfill, these are the key criteria for the temperature controllers teco wh/whx. As one-circuit and multi-circuit units, our modular temperature controllers in the teco whx series cover a wide performance spectrum. Heating capacities of 12 to 600 kW, max. possible cooling capacities up to 1460 kW* and pump flow rates of max. 200 m3/h are impressive basic data of these technically sophisticated temperature controllers for operation with compressed water up to 220 °C.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

HIGH PERFORMANCE TEMPERATURE CONTROL DEVICE WITH HIGH COOLING CAPACITY, HIGH FLOW RATE AND REDUCED ENERGY CONSUMPTION. Due to the design, dimensioning and selection of the used components, enersave temperature control systems are the most efficient systems on the market with the highest flow rates at operating point. In the selection series we used the most frequently selected equipment features and heating performance of the proven premium series advanced. The protemp selection temperature control unit is particularly suitable for the supply of multi-circuit water distributors and is designed for the display of up to 6 external proflow temperature control channels.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

With the decentralised solution, gwk adds a machine series that offers a high level of flexibility for numerous applications to its portfolio. The customer can individually and precisely set the ideal cooling water temperature for every production machine and for every process in production. Thanks to the direct connection to the consumer, there are no thermal losses, but instead a high flow rate and constant pressure. The weco wd series consists of easy to operate plug&play machines that can easily be installed and commissioned. Three processes can be run with the solution: Free cooling, refrigeration process for low temperatures down to -5°C and temperature control up to 90 °C –everything can be chosen as desired. There is a total of four models with cooling powers between 14 kW and 36 kW (at 15 °C feed flow temperature) and heating powers between 9 kW and 36 kW.

Request for a quoteResults for

Machining of plastic - Import exportNumber of results

120 ProductsCountries

Company type

Category

- Plastics - machines and material for industry (75)

- Silicones (6)

- Welding, plastics - machinery (5)

- Punching machines, plastic (4)

- Wrapping machines (4)

- Automation - systems and equipment (2)

- Plastics - industrial machinery and equipment (2)

- Rolling mills - machinery and installations (2)

- Laser - cutting and welding machines (1)

- Punching machine tools (1)

- Electric motors - aC (1)

- Fittings, pipe, tube and hose - plastic (1)

- Frames and mountings, photograph (1)

- Furniture for kitchens (1)

- Industrial tools (1)

- Package stamping machinery (1)

- Packing and packaging - machinery and equipment (1)

- Pedal boats (1)

- Radiators, engine (1)

- Recycling - machines and installations (1)