- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine techniques

Results for

Machine techniques - Import export

ETH MESSTECHNIK GMBH

Germany

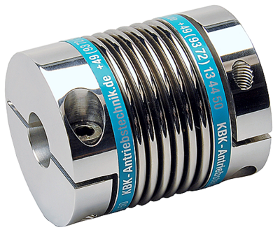

Metal Bellows Coupling with collet clamps / Hub material: aluminum Backlash-free metal bellows coupling with clamp hubs Hub material: aluminum Alternatively to steel executions we recommend our series KB4AL from size 80 - 500 For shaft diameters from 10 – 70 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Easy assembly and low inertia Perfect bellows coupling for connecting servo motors, e.g. in machine tools, automation techniques, packing machines, wood working machines Torque range: 18 – 500 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

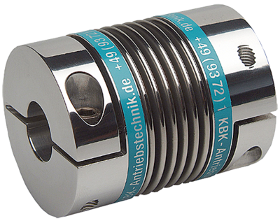

Metal Bellows Coupling with collet clamps, compact Backlash-free metal bellows coupling with compact clamp hubs For shaft diameters from 10 – 70 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Perfect bellows coupling for connecting servo motors, e.g. in machine tools, automation techniques, packing machines, wood working machines Torque range: 18 – 1400 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling with collet clamps Backlash-free metal bellows coupling with clamp hubs Hub material: up to 60Nm – aluminum, up from 80Nm - steel For shaft diameters from 10 – 80 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Easy to assemble Perfect bellows coupling for connecting servo motors, e.g. in machine tools, automation techniques, packing machines, wood working machines Torque range: 18 – 1400 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling axial pluggable Backlash-free metal bellows coupling as axial pluggable execution Easy assembly / disassembly by simply plugging / pulling the coupling parts High tensile aluminum and special coatings ensure a durable solution at low mass / inertia For shaft diameters from 10 – 70 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Perfect bellows coupling for servo drives, e.g. in testing equipment, automation techniques, packing machines Torque range: 18 – 500 Nm

Request for a quote

ETH MESSTECHNIK GMBH

Germany

Metal Bellows Coupling with split hubs Backlash-free metal bellows coupling with split hubs For shaft diameters from 10 – 80 mm High torsional stiffness, compensation of shaft misalignment at low restoring forces Radial assembly! Due to the split hub design shafts can be mounted and adjusted before the assembly of the coupling Perfect bellows coupling for servo drives, e.g. in testing equipment, automation techniques, packing machines Torque range: 18 – 1400 Nm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STRONG MAGNETS GMBH

Germany

Neodymium magnet (aka NdFeB magnet), is the third generation of rare earth magnet, which is composed of Neodymium, Iron, Boron and a few transition metals. With high remanence, high coercive force, high energy product, and high performance /cost, Neodymium magnet is currently the strongest magnet available in the world. Manufacturing Process Neodymium, Iron, Boron and a few transition metals will be mixed into the Neodymium powder, then fine Neodymium powder will be compacted in a die and sintered, fusing the powder in a solid state. There are two ways of pressing die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances. Machining & Tolerance Generally, Neodymium magnet must be machined using diamondgrinding techniques. Sometimes, machining operations may be performed on Neodymium materials with carbide tools, but surface finishes thus obtained may be less than optimal.

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

The aluminum lags are produced precisely for all machine types. Optimized processing techniques tailored to the material ensure that the pins are securely seated. Thanks to modern CNC technology, the needle arrangement and angle precisely meet the requirements of the application. For a high-quality replacement of the original equipment at an optimal price-performance ratio, we are looking forward to your inquiry! A questionnaire is available below, alternatively, send us a sketch. The specification of machine type and desired needle density often suffice.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

MAXIMUM PERFORMANCE! Compared to vibratory finishing vibrators, Trowal Turbotron centrifugal units offer up to 10 times the grinding power. grinding performance. Turbotron machines are mainly used for the removal of heavy burrs and for edge rounding edges on small and medium-sized mass-produced parts. However, by applying special process techniques, Turbotron machines can also be used for fine grinding and even polishing. even polishing. HOW IT WORKS The rotation of the turntable (60-250 rpm) accelerates the abrasive / workpiece mass and the centrifugal force on the inner wall of the stationary work bowl deflects it upwards. deflected. Due to the onset of gravity, the mass slides back onto the turntable, from where it is accelerated again from there.

Request for a quoteResults for

Machine techniques - Import exportNumber of results

9 ProductsCountries

Company type