- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine tables

Results for

Machine tables - Import export

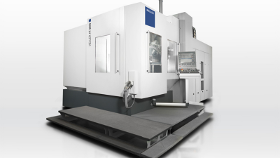

GEBR. HELLER MASCHINENFABRIK GMBH

Germany

5-axis machining centres for powerful complete machining Setting standards in 5-axis: 5-sided and 5-axis simultaneous machining in HELLER quality Highlights Maximum output at optimum quality due to HELLER's extensive process experience Higher availability thanks to adequate speeds and proven HELLER components Innovative spindle technology in three variants providing optimum process stability (swivel head with PCU 63 or SCU 63, fork head with PCT 63) Two control options: Heidenhain iTNC 530 or Siemens Sinumerik 840D sl Advantages Reduced costs thanks to flexible complete machining Optimised life-cycle costs due to innovative manufacturing concept Two machine variants for maximum manufacturing flexibility: workshop machine FT (table loading) for machining of individual parts in tool and die manufacturing and production machine FP (pallet changer) for series production

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

rotating spindle machine for coating rotationally symmetrical parts

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine with rotary indexing table and tool magazine. Automatic tool changer with HSK spindle tools. Mosts common tools used are tampico and sisal fibre brushes for bottom, bottom radius and side wall polishing.

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Soft turn of the bundles Low maintenance Optimal access Very quiet operation Intrinsically safe machine, protection door-less concept Bypass without bundle turning, manually Upstream and downstream interlocks with complete plug connection In conveying direction left or either right Power cable, length 3m OPTIONAL: Bypass without bundle turning, automatically OPTIONAL: One pop-out roller on entry side OPTIONAL: Machine movable Table height steplessly adjustable Many specific options available, easily configurable

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Avola GAMA 65 V revolving cross cut / rip cut saw Equipment / scope of supply- Cutting heights 90° / 245 mm - 45° / 164 mm - 30° / 113 mm - Machine table with lateral movement approx. 400 mm with pneumatic brake system - Machine hood with lateral PVC protective curtains - pneumatic clamping cylinder left - right - pneumatic cross-cutting operation using two-hand control - electrical saw blade inclination 90 – 30° - Revolving table 0 - 270° - Laser light for cross-cutting - Saw bla de height adjustment via mechanical stop system with scale - TCT saw blade 650 mm, dust extraction spigots 160 / 125 mm - Drive motor 12 kW – direct motor speed 1/min – 3,000 - Saw blade speed 1/min – 3,000

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Avola GAMA 80 V carpenter’s circular saw bench for professional applications Equipment / scope of supply- Motor rating 22 kW (P1) / 400 Vac-50 Hz star delta start gear drive - Motor speed rpm 3.000 / sawblade speed rpm 2.200 - Cutting height 90° / 310 mm – 45° / 217 mm – 30° / 149 mm - Electrical sawblade inclination 90 – 30° - Revolving table 0-270° - Machine table with lateral movement 650 mm - Automatic vertical pneumatic clamping cylinders right / left - Laser light for cross cutting - TCT-sawblade, 800 x 30 x T90 - Dust extraction spigots 160 / 160 / 80 / 80 mm - Sawblade height adjustment via mechanical stop system, with measuring scale, easy to adjust - DUO infeed / outfeed devices

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

LATERALLY MOVABLE UNDERTABLE CROSS-CUT SAW / RIP CUT SAW FULLY AUTOMATIC CIRCULAR SAW FOR POSITIONING AND CONTROLLING VIA TOUCHSCREEN WITH LENGTH MEASURING SYSTEM EXENSO COMFORT (PUSHER SYSTEM) Application : Length stop system (pusher operation), revolving table with lateral movement and sawblade inclination via servo - motor for positioning (rip cut, cross cut, mitre cut or compound mitre cut) of heavy workpieces, i.e. carpenter industry, gluelam industry, log house industry, wooden frame work, solid wood, etc. Equipment / scope of supply : - Motor rating 12 kW / 400 Vac-50Hz, star / delta start, direct driven - Motor speed 3.000 rpm - lateral movement of machine table 400 mm with pneumatic brake system - Electrical sawblade inclination 90-30° via servo motor - Laser light for cross cutting - Cutting height at 90° / 245 mm – 45° / 164 mm – 30° / 113 mm - TCT - sawblade 650 x 30 x T 54

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Do you have individual requirements for your laser processing center that our standard laser system of the LS series cannot meet? We develop together with our customers from stand-alone systems to integration into existing lines. In doing so, system know-how meets automation and laser technology: - robot solutions - portal variants - rotary table machines - sliding table systems - scanner solutions - integrated solutions based on VARIOMODUL® or, - at your request, on standard laser machines of the LS series For further information please take a look at our homepage.

Request for a quote

PRESSTA EISELE GMBH

Germany

Base 3000 mm, with hardened guides in x-direction, 3.000 – 8.000 mm Electric device – operation via 2-hand safety control, setting mode to adjust drilling depth – key switch Drilling units with stand and linear guides in X-direction, shafts for manual adjustment of drilling height, working range 125 mm (drill to back wall), Positioning in X and Y direction by scale, Profile height max. 200 mm Either toothed drill chucks or multy spindle heads available Drilling units, motor 1,5 KW, 400 V, 50 Hz, 3000 r.p.m., pneumatic down feed max. 200 mm, hydraulic damped Drilling performance up to Ø 16 mm Zero-stop for X-direction mounted on left side of machine, adjustable 0 – 100 mm Table with pneumatic horizontal profile clamps

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

Highly accurate absolute angle measuring system with flat design and integrated bearing. Magnetic operating principle therefore extremely insensitive Perfectly suited for applications in CNC machine tools such as rotary tables. With serial interfaces for Fanuc, Mitsubishi and Yaskawa CNC available.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

On request, we can integrate all of our interferometer systems into our UP machine for quality control in one setting. Be it with a simple strip display or a fully automatic strip evaluation for visualizing the 3D topography. The technical specifications of the intermeter systems are identical to the stand-alone systems.The larger travel range of the MMC900 offers the option of mounting a 6 “interferometer next to the Z axis. After machining the workpiece, the X-table is moved under the interferometer and the surface is measured.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

High-precision absolute angle encoder with flat design with integral bearing Magnetic operating principle therefore extremely insensitive Perfectly suited for applications in CNC machine tools such as rotary tables Serial interfaces for Siemens and Fanuc. Siemens version with Functional Safety certification.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Economical and versatile: the ASB 400 conveyor derinder with a wide range of applications. The entry-level model can be used (open) as combination machine with carriage table or (closed) with pressing unit and conveyor. Automatic derinding of all cuts, such as cheek, belly and loin of pork, as well as fat on shoulder and ham. In open operation, suitable for derinding all round cuts, such as ham, shoulder or knuckle. Advantages Clean removal of rind without residues Infinite adjustment of the rind/cutting thickness Ergonomic machine design: short setup times, simple operation with maximum safety Options: Pressure rollers in various hardnesses Special voltage

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 4 spindles OP 10 with 4 part clamping on workpiece carrier unit OP 20 with 4 workpieces on 2 rotary tables (5-axis machining

Request for a quote

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

WiTEC Performance is the perfect solution for the most precise and fastest machining of your sheet material! The Performance is the flagship solution of the WiTEC machine family. A machine concept based on a FEM optimized design, built using premier precision components, and equipped with linear magnet motor technology, the Performance is able to achieve the highest levels of precision and speed, up to 80m/min! Thanks to the combination of Wissner’s innovative and patented hold&press Technology and sophisticated Vacuum System, you can mill even the smallest parts all the way through the finishing cut-out! No need for any adhesive paper or foil, no need for leaving connector tabs, and no deburring or cleaning is necessary! The ready-finished parts will go directly from the machine table to the end customer!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The C 650 uses a modification of HERMLE's tried-and-tested gantry-type design, with a mineral-cast machine bed. The integrated, rigid clamping table can cope with workpieces up to a maximum of 3000 kg (1050 x 900 x 600 mm) in the 3-axis version, making it ideal for toolmaking, mould construction and machine construction. The swivelling rotary table of the 5-axis version can accommodate workpieces up to 1500 kg (Ø 900 x 600 mm), allowing for highly precise machining. The traverse path in the stainless-steel-clad working area comprises 1050 x 900 x 600 mm with a vertical table clearance of 775 mm and a door aperture of 1050 mm. Ideal parameters for simple and safe crane charging. The C 650 has an integrated tool magazine for 42 tools. The control panel of the C 650 is also designed to swivel easily to the magazine loading location, so the operator can enter the tool data directly into the tool table in the control system.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

MBX magnetic clamping blocks have opposite clamping sides that are activated when actuated. They are designed to clamp workpieces on steel surfaces such as machine or assembly tables. Several MBX can also be connected together via the internal hexagon of the indexing shaft to clamp longer or larger workpieces.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FXL-R round magnetic chucks in square pole technology are especially suitable for use on the lathe and on rotary tables of machining centers. The frame construction of the FXL plate can be equipped with centering elements at the front on the clamping side as well as at the rear. All FXL magnetic chucks can be operated with FXL-C or FXL-CT control units.

Request for a quote

FRIMO GROUP GMBH

Germany

A concept for higher productivity FRIMO VarioForm inline and rotary table thermoforming machines are primarily used in the automotive industry and are ideally suited for forming a wide range of films and sheet materials.

Request for a quote

FRIMO GROUP GMBH

Germany

A concept for higher productivity FRIMO VarioForm inline and rotary table thermoforming machines are primarily used in the automotive industry and are ideally suited for forming a wide range of films and sheet materials.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Rotary table machines are used for applications that involve production of large counts in cycle time-optimized manner. The machine design allows for dividing the application into several process steps. The number of operating stations depends on the respective task. The individual operating steps are performed in the different stations within the work space simultaneously with loading in the loading area. Indexed tool change is optionally possible.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Shuttle table machines are characterized by an operating area that is separated from the loading station. The plastic parts to be welded can thus be optimally loaded into the equipment. Thanks to good accessibility, assembly and loading tasks can be easily performed. Can optionally be designed with one or more work stations. Approach of several operating positions is performed by means of a freely programmable linear drive. In this way, weld tasks can be divided into individual process steps. Tool change systems: optionally available.

Request for a quote

ALPHA LASER GMBH

Germany

The laser welding systems of the AL series can be used universally. They might be integrated into existing machine structures or used with an application device for manual welding. In combination with our NC-controlled laser machining table AL-T you get a real professional solution. We offer the required performance class for every application. You can choose between 75 and 900 W. There is a wide range of processing lenses and equipment options for these laser systems. Regardless of whether you use a simple 90 ° deflection lens, the tilt-swivel lens or our circular welding lens - the laser beam always reaches the desired point on the workpiece with pinpoint accuracy. Additional equipment options are optionally available for the AL, such as: • Micro welding device for a welding spot diameter <100 µm • Rotary axis module for cylindrical welds • automatic wire feeder • Workpiece holder • camera system •…and much more

Request for a quote

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

The compact design allows to generate high centrifugal forces and requires minimum space. This is often necessary when used in machines. Fields of application are e.g.: Ram vibration of block making machines, vibrating table, battery formworks. Special Features are: • Centrifugal force from 0,5 kN to 16,5 kN • Speed from 1500 RPM to 3000 RPM

Request for a quote

STARRAG GMBH

Germany

Gantry design For machining of largest and heaviest workpieces Droop+Rein offers a floor guided gantry machine line. Best accessibility and utilisation of floor space for largest workpieces combined with highest flexibility in size and configuration. Cross rail, moveable (GS) or fixed (GFS) Economic machining of largest components – flexible, dynamic and precise Floor space savings compared to table moving machines In line with the modular principle – various controls, table configurations, milling head/spindles and tool changer configurations

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 2 heads diving filling nozzles Star capping and closing system Herma Labeling machine 1 heads One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 2 heads diving filling nozzles Star capping and closing system Herma Labeling machine 1 heads One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quoteResults for

Machine tables - Import exportNumber of results

61 ProductsCountries

- Germany (61)

- Bonn, Düsseldorf and North Rhine and Westphalia (10)

- Frankfurt am Main and Hesse (4)

- Hannover and Lower Saxony (2)

- Kiel and Schleswig-Holstein (7)

- Leipzig and Saxony (3)

- Mainz and Rheinland-Pfalz (2)

- Munich, Nuremberg and Bavaria (10)

- Potsdam and Brandenburg (5)

- Stuttgart, Freiburg and Baden-Wurtemberg (17)

- Weimar and Thuringia (1)

Company type

Category

- Machine tools - metal machining (7)

- Adjustment - machine tools (5)

- Food industry - machinery and equipment (5)

- Milling - machine tools (3)

- Packing and packaging - machinery and equipment (2)

- Machine tools, metal machining - parts and accessories (2)

- Mechanical engineering - custom work (2)

- Woodworking - machinery and equipment (2)

- Measurement - Equipment & Instruments (2)

- Precision measuring instruments (2)

- Laser - cutting and welding machines (1)

- Milling - steels and metals (1)

- Sandblasting equipment (1)

- Automation - systems and equipment (1)

- Bending machine tools (1)

- Carpentry - machinery and equipment (1)

- Construction - Machines & Equipment (1)

- Disks, magnetic (1)

- Gears (1)

- Industrial cutting machine tools (1)