- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine belts

Results for

Machine belts - Import export

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

KEIPER has an extensive range of flat belts, including high-performance flat belts, power transmission belts, folder-gluer belts, machine belts, tangential belts and conveying belts. For the perfect power transmission, conveying or control solution in any industrial sector. Keiper flat belts are designed to meet your specific requirements and applications, and, accordingly, they are made to size. Our flat belts are made of different traction layers and composite structures with different coatings such as nitrile-butadiene rubber, leather and surface structures. FLEXA With a polyamide or polyester reinforcement With a one-sided or two-sided coating of nitrile-butadiene rubber, highly resistant to abrasion and wear Different surface structures CROMA With a polyamide reinforcement With a one-sided or two-sided coating of chrome-split leather, highly resistant to abrasion and wear Butt leather belts Made of pure prestretched butt leather Rubber-and-fabric belts

Request for a quote

IMM MASCHINENBAU GMBH

Germany

Rigid machine for heavy duty belt grinding. The machine can be adjusted for horizontal or vertical position. Various options include: Dust extraction, chamfering device, angle guide roller, longitudinal stop.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC controlled machine for belt grinding and polishing stainless steel weld seams. Belt grinding on the contact wheel or slack belt unit is possible for edge profiling.

Request for a quote

EUGEN LÄGLER GMBH

Germany

Worldwide: known, used and admired across the globe! The HUMMEL® is powerful, efficient and reliable. With its optimal dust extraction you are able to work almost dust free. The sophisticated and durable technology for perfect sanding along with its enormous performance quality make the HUMMEL® the undisputed number one machine for sanding wooden floors. It has been convincing craftsmen all over the world for over half a century. It is simultaneously powerful and easy to operate and maintain. Both changing the sanding belt and dismantling the machine are extremely simple. The HUMMEL® can be ordered with or without the powerful LED work light. Applications with the HUMMEL®: The HUMMEL® belt sander is mainly used for sanding wooden floors. It enables precise and economical sanding of both small and large surfaces.

Request for a quote

EUGEN LÄGLER GMBH

Germany

The efficient solution for commercial areas and public buildings, such as sports or industrial halls. The SUPERHUMMEL is the first choice for the efficient sanding of large areas due to its powerful motor and its extra wide sanding drum. The SUPERHUMMEL stands for top sanding quality combined with a maximum area capacity. It is very user-friendly - easy to operate and at the same time to maintain. Both, changing the sanding belt and dismantling the machine, are extremely simple. The optimal dust extraction and the robust construction of the machine are a matter of course. Applications with the SUPERHUMMEL: The high-performance floor sanding machine with 300 mm (approx. 11.8”) sanding drum width has especially been designed for the efficient treatment of large-scale wooden floors, e.g. commercial areas and public buildings. The SUPERHUMMEL equipped with the hard rubber drum ensures an even removal on softwood floors with strong knots.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

In our catalog for coatings, machining and profiles for belts, you will find all the different possible materials for coatings of belts. The possibilities for machining and amny examples for transportation cleats and profiles.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Coatings for movement. Today, the effectiveness of state-of-the-art production lines more than ever before calls for a high degree of specialization. The requirements posed with respect to movable components are rising steadily, just like the performance and calculation of operating time. KEIPER timing belts are finished with high-quality coatings in order to meet the required technical specifications accurately and reliably. Many different types of mechanical processing are available: milling in all directions, profiling, punching for vacuum applications as well as grinding edges and surfaces. Our extensive know-how in combining the right coating and mechanical processing options leads to precisely the specific designs required by our customers.

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Extremultus machine tapes are vital components of machinery in many industrial applications. Tension members made of polyester/aramide fabric, polyamide sheet or elastic urethane make them ideal for a range of different areas. Siegling Extremultus machine tapes offer the following characteristics: superior abrasion-resistant coatings with constant friction coefficients and long service lives; surface patterns and surface coatings, as well as electrostatic features to suit requirements; damping characteristics tailored to requirements (depending on the tension member); low elongation at fitting, low shaft load.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

The 72711 belt sander offers all benefits of the 72780 series but with only one side. It is made for heavy duty applications. For sitting or standing operation. Variable cutting speeds from 900 to 2,800 Rpm. Optionally with frequency converter.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

Heavy duty polishing and belt grinding jack. For belt linishing, grinding and polishing of surgical instruments, faucets, castings and other work pieces.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

Heavy duty belt sanding and polishing jack for industrial applications. Compact double ended design. Floor standing pedestal. Rapid belt tensioning and tracking. Also for alumimun polishing.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper’s high-performance FLEXA flat belts are made of fully synthetic polyamide or polyester fabric and polyamide foil, with or without a suitable adhesion coating made of nitrile-butadiene rubber, depending on the wide range of possible power transmission and conveying applications. Fitted with a polyamide or polyester reinforcement With a one-sided or two-sided coating of nitrile-butadiene rubber, highly resistant to abrasion and wear Different surface structures FLEXA belts can be used as: Power transmission belts Folder-gluer belts Machine belts Tangential belts Spindle belts Properties + Suitable for a large temperature range + High resistance to abrasion + Very good dynamic properties + Resistant to oils and acids + Outstanding anti-static properties of black NBR - Gets brittle when exposed to UV light and ozone (only for limited outside use) - Processing is work and energy intensive (vulcanization, hardening)

Request for a quote

BIZERBA SE & CO. KG

Germany

100 % control of dough in the bakery industry Due to its particularly robust design, the CWPmaxx Bakery checkweigher is ideally suited for use in the hygienically sensitive production environment of the bakery industry. The hygienic design required for this industry is exemplary. The open design facilitates cleaning and minimises product deposits. No or few parts designed to wear a continuous belt, no deflection rollers, and no bearings. A long-lasting drum motor provides reliable propulsion. Optimise your lines' efficiency and increase profits with fill quantity and process control with the CWPmaxx Bakery checkweigher. Normally checkweighing systems can experience hygiene problems due to the overall design. Normally at the point, where in the in feed belt weighing and discharge belts are located. On a normal checkweigher dough will or can drop from the conveyor belt systems and accumulate in the machine. Belts are normally thinner than the conveyor and thus an accumulation can...

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

With the newly developed FAPI-SWITCH series, we have succeeded in designing deflection pulleys in a lightweight system design with an unprecedented smoothness and smoothness of running that set new standards in the belt grinding process. Due to the flexibility, also with regard to different dimensions, belt elephant machines of all brands can be equipped with these deflection rollers. We would be pleased to advise you on which return pulleys can be used in your processing, in order to achieve top process results.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Discover German engineering at its best with our drive components for conveyor belts. Manufactured from high-quality materials, they guarantee efficient and reliable material movement. Wire Belt offers you guaranteed precision-manufactured sprockets, drive shafts and pulleys. Each component is carefully manufactured in Germany to fulfil the highest quality standards. The durability of our drive components reduces follow-up costs and ensures smooth production processes. Our employees are on hand to advise you throughout the life cycle of every project. Based on your needs, you will receive the best recommendation for the respective material requirements in combination with the motor and the conveyor belts. High standards are essential, especially in the food industry. With Wire Belt you will find the right partner.

Request for a quote

MPT DOSING GMBH

Germany

/ Static Inline Mixers Dynamic Inline Mixers Dynamic inline mixers have, contrary to static mixers, a driving motor with variable agitator speed, providing for the required mixing energy. The main field of application for dynamic inline mixers is the intensive and adjustable mixture of polymer flocculation agents with the sludge to be dewatered on dewatering machines like (belt) filter presses. Using dynamic inline mixers the active ingredient contained in the polymer is dispersed evenly in the sludge to be dewatered, resulting in a noticeable improvement of the dewatering characteristics and a considerable reduction of the required flocculation agent. A suboptimal mixture of the flocculation agents is often compensated by a considerable increase of the dosed quantity. In many applications the flocculation agent is dosed in a stronger dilution to improve the miscibility. However, this means that water which actually should be detracted from the system is now added to the system. I

Request for a quote

XBK-KABEL XAVER BECHTOLD GMBH

Germany

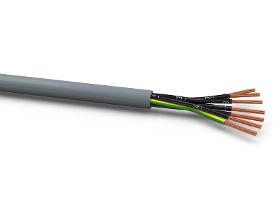

PVC-Control cables are used in tool-machines, conveyor belts, production lines in machinery production, in air-conditioning and in steel production. They are used for installing in dry, moist and wet rooms, specially under the terms of industrial environment. Outdoor use only with UV-protection allowing for temperature range. GLOBALFLEX®-control cables are suitable for medium mechanical stresses with free movement without tensile stress or forced movements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XBK-KABEL XAVER BECHTOLD GMBH

Germany

GLOBALFLEX®-CY-control cables are used in tool-machines conveyor belts, production line in machinery production, in air-conditioning and in steel production for low loss data and signal transmission. They are used for installing in dry, moist and wet rooms, especially under the terms of industrial environment. Outdoor use only with UV-protection allowing for temperature range. GLOBALFLEX®-CY-control cables are suitable for medium mechanical stresses with free movement without tensile stress or forced movements. The high level of screening ensures a high degree of interference protection. the screening density assures disturbance free transmission of all signals and impulses. The product corresponds to the directive 2014/35/EU (low voltage directive).

Request for a quote

TOPTICA PHOTONICS AG

Germany

TOPTICA’s TeraFlash smart utilizes a proprietary scheme dubbed ECOPS ("electronically controlled optical sampling"). The system comprises two synchronized femtosecond lasers, eliminating the need for a mechanical delay. This results in extremely high measurement speeds: the TeraFlash smart acquires 1600 complete terahertz waveforms per second, enabling terahertz-based thickness gauging at unprecedented speed. The system thus lends itself to measurements on rapidly moving samples, e.g. conveyor belts, papermaking machines, or extrusion lines. Learn more about TOPTICA's advanced terahertz solutions.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

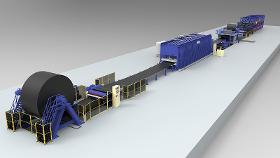

One of Siempelkamp’s core competences is the design and manufacture of presses for the rubber industry. With our expertise in this eld we are the world’s number one in steel-cord and conveyor-belt presses with many of the conveyor belts used around the world being manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straightrunning stability. Siempelkamp's excellent manufacturing and high-quality plants are eld proven. Services Single-source supplier Uniform pre-tensioning of the individual steel cables Best pressure distribution in our vulcanising presses Cable clamping and tensioning device with a heavy clamp Compactor lorry with pre-press Pull-roll stand Reeling elements Advantages Excellent thickness tolerances due to multi-cylinder press without requiring press bolsters Safe vulcanizing process for various belt widths by controllable pressure distribution Transparent and controllable production process

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

Continuous blasting – Excellent, highly automated processing The selected blasting medium is directed towards your workpieces at high speed using blast wheels. This ensures high blasting performance and optimum use of energy. Using this technology in a continuous process offers several advantages over batch processing: — Continuous workpiece feeding — Easy to integrate into production processes — Simplified parts flow That is why our continuous belt blasting units are frequently used to replace conventional batch systems. With their easy workpiece handling and excellent blasting results, they are even used as replacements for suspended-line systems.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

This model is well suited for efficient, economical processing of circular workpieces via surface and step grinding operations. There is no lost time through deceleration, acceleration and reversal as with conventional reciprocation grinding. The grinding wheel remains in contact with the workpiece throughout the grinding process. Single workpieces can be located centrically on the table while multiple workpieces can be located concetrically to optimize table space utilization. A tilting table option allows grinding of chamfers or blade edges (i.e. circular blades), where the table can be tilted +/- 5 degrees. The high-precision rotary table is belt driven. This machine is offered with the xpressCube SPS controls package. A software option is available for step grinding operations. Benefit Overview — Compact and robust machine design — High productivity through continuous contact between wheel and workpiece — High long-term precision — Precision rotary table — Easy to operate

Request for a quoteResults for

Machine belts - Import exportNumber of results

23 ProductsCountries

Company type

Category

- Conveyor belts (5)

- Copper wires and cables (3)

- Metallurgy and iron and steel industry - machinery and installations (3)

- Wood sanding machines (2)

- Metallurgy - machinery and installations (1)

- Adjustment - machine tools (1)

- Forming, rubber - machinery (1)

- Grids, gratings and wire mesh (1)

- Measurement - Equipment & Instruments (1)

- Polishing - machine tools (1)

- Shot blasting - steels and metals (1)

- Transmission belts (1)

- Wheels, castors and rollers (1)