- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- lubricant application

Results for

Lubricant application - Import export

GLT BEARINGS GMBH

Germany

Wrapped composite sliding bearing steel / Special PTFE coated Maintenance-free dry sliding bearing | DIN 1494 / ISO 3547 TEF-MET/P is a versatile dry sliding bearing with PTFE sliding layer. Therefore, no lubrication is necessary. However, it is very well suited for lubricated applications (e.g. hydraulic oil lubrication). For technical details, please visit the product page on our website!

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent at foundry operations injection moulding, blowing and extruding processes of plastics and elastomer Avoids the sticking of e.g. adhesives and sealing excess or water wetting Sliding agent against noisy rubbing of plastics, elastomers and metals together or against each other Lubrication of cutting edges in the paper, cardboard, veneer layer and textile processing machines For easy retracting of plastic and rubber profiles, e.g. in the door and window production Advantages and benefits High efficiency because of excellent netting of the surface and building of extremely thin lubricating films Separating effect with antistatic properties Manifold applications for permanent lubrication, protection, maintaining and impregnation Neutral behaviour against plastic and elastomers Resistant against water and atmospheric influences

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent at foundry operations injection moulding, blowing and extruding processes of plastics and elastomer Avoids the sticking of e.g. adhesives and sealing excess or water wetting Sliding agent against noisy rubbing of plastics, elastomers and metals together or against each other Lubrication of cutting edges in the paper, cardboard, veneer layer and textile processing machines For easy retracting of plastic and rubber profiles, e.g. in the door and window production Advantages and benefits High efficiency because of excellent netting of the surface and building of extremely thin lubricating films Separating effect with antistatic properties Manifold applications for permanent lubrication, protection, maintaining and impregnation Neutral behaviour against plastic and elastomers Resistant against water and atmospheric influences

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent at foundry operations injection moulding, blowing and extruding processes of plastics and elastomer Avoids the sticking of e.g. adhesives and sealing excess or water wetting Sliding agent against noisy rubbing of plastics, elastomers and metals together or against each other Lubrication of cutting edges in the paper, cardboard, veneer layer and textile processing machines For easy retracting of plastic and rubber profiles, e.g. in the door and window production Advantages and benefits High efficiency because of excellent netting of the surface and building of extremely thin lubricating films Separating effect with antistatic properties Manifold applications for permanent lubrication, protection, maintaining and impregnation Neutral behaviour against plastic and elastomers Resistant against water and atmospheric influences NSF H1-registered

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent at foundry operations injection moulding, blowing and extruding processes of plastics and elastomer Avoids the sticking of e.g. adhesives and sealing excess or water wetting Sliding agent against noisy rubbing of plastics, elastomers and metals together or against each other Lubrication of cutting edges in the paper, cardboard, veneer layer and textile processing machines For easy retracting of plastic and rubber profiles, e.g. in the door and window production Advantages and benefits High efficiency because of excellent netting of the surface and building of extremely thin lubricating films Separating effect with antistatic properties Manifold applications for permanent lubrication, protection, maintaining and impregnation Neutral behaviour against plastic and elastomers Resistant against water and atmospheric influences

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent at foundry operations injection moulding, blowing and extruding processes of plastics and elastomer Avoids the sticking of e.g. adhesives and sealing excess or water wetting Sliding agent against noisy rubbing of plastics, elastomers and metals together or against each other Lubrication of cutting edges in the paper, cardboard, veneer layer and textile processing machines For easy retracting of plastic and rubber profiles, e.g. in the door and window production Advantages and benefits High efficiency because of excellent netting of the surface and building of extremely thin lubricating films Separating effect with antistatic properties Manifold applications for permanent lubrication, protection, maintaining and impregnation Neutral behaviour against plastic and elastomers Resistant against water and atmospheric influences

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Dry lubrication for applications where pastes or powders have been used up until now Chain lubrication of heavily loaded chains in temperature ranges in which oil or grease lubrication is not possible For example, in annealing, stoving and baking ovens for aluminium tube manufacturing, in painting systems or in baking lines Advantages and benefits Hygienically harmless as defined in German LFGB Approved by Nuremberg LGA for use in food processing technology NSF H2 registered Economical due to low consumption Optimum wear protection at high pressures and extreme temperatures Can be mixed with water in ratio of up to 1:5

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent at foundry operations injection moulding, blowing and extruding processes of plastics and elastomer Avoids the sticking of e.g. adhesives and sealing excess or water wetting Sliding agent against noisy rubbing of plastics, elastomers and metals together or against each other Lubrication of cutting edges in the paper, cardboard, veneer layer and textile processing machines For easy retracting of plastic and rubber profiles, e.g. in the door and window production Advantages and benefits High efficiency because of excellent netting of the surface and building of extremely thin lubricating films Separating effect with antistatic properties Manifold applications for permanent lubrication, protection, maintaining and impregnation Neutral behaviour against plastic and elastomers Resistant against water and atmospheric influences MOSH/MOAH-free NSF H1-registered

Request for a quote

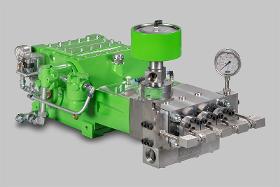

KAMAT GMBH & CO. KG

Germany

High-Pressure Cleaning, Load Change Systems and Pressure Test Systems If your application requires forced lubrication and an oil cooler may be required, the powerful K9000-3G three-plunger high-pressure pump is an alternative to the smaller K8000-3G three-plunger high-pressure pump. Like the compact K8000 model, this 90 kW high-pressure pump is suitable for smaller industrial applications such as industrial cleaning, jetting or process engineering. SPECIAL FEATURES - Capacities at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on fluid - Speed range 10-100% depending on rod force - Forced lubrication gearbox (> 75 kW with oil cooler) - Standard gear ratios i = 2.75 - 3.22 - 3.68 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request - Vertical operation possible

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SFZ are designed for sandwich plate mounting in hydraulic and lubrication applications, with a maximum operating pressure of 315 bar / 4.560 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for sandwich plate mounting ▪ Available as left or right version Operating Pressure ▪ Max. 315 bar / 4.560 PSI Nominal Flow Rate ▪ Max. 30 l/min / 8 US GPM Materials ▪ Filter head: Free Cutting Steel ▪ Filter bowl: Cold Drawn Steel Media Compatibility ▪ Mineral oils, other fluids on request

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SF-SM are designed for manifold block mounting in hydraulic and lubrication applications, with a maximum operating pressure of 315 bar / 4.560 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for manifold mounting ▪ Threaded mounting holes and fluid ports on side of head ▪ Option of standard or two-part top loader version Operating Pressure ▪ Max. 315 bar / 4.560 PSI Nominal Flow Rate ▪ Max. 1.135 l/min / 300 US GPM Materials ▪ Filter head: Spheroidal Graphite Cast Iron ▪...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Medium Pressure Filters type SMPF are designed for in-line hydraulic and lubrication applications, with a maximum operating pressure of 110 bar / 1.600 PSI. Used together with STAUFF SME series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass valve Clogging Indicator ( available as an option ) ▪ Visual or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SME series Construction ▪ Medium pressure filter designed for in-line assembly Operating Pressure ▪ Max. 110 bar / 1.600 PSI Nominal Flow Rate ▪ Max. 90 l/min / 25 US GPM Connections ▪ Option of BSP or SAE O-ring thread Materials ▪ Filter head: Aluminium ▪ Filter bowl: Aluminium Media Compatibility ▪ Mineral oils, other fluids on request

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SF-TM are designed for manifold block mounting in hydraulic and lubrication applications, with a maximum operating pressure of 315 bar / 4.560 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for manifold mounting ▪ Threaded mounting holes and fluid ports on top of head ▪ Option of standard or two-part top loader version Operating Pressure ▪ Max. 315 bar / 4.560 PSI Nominal Flow Rate ▪ Max. 1.135 l/min / 300 US GPM Connection ▪ BSP Materials ▪ Filter head: Spheroidal...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Medium Pressure Filters type SFA are designed for in-line hydraulic and lubrication applications, with a maximum operating pressure of 160 bar / 2.320 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ Medium pressure filter designed for in-line assembly ▪ Threaded mounting holes on top and fluid ports on side ▪ Low weight and compact design Operating Pressure ▪ Max. 160 bar / 2.320 PSI Nominal Flow Rate ▪ Max. 240 l/min / 70 US GPM Connections ▪ Option of BSP, NPT, SAE thread or SAE flange (ISO 6162-1) Materials ▪ Filter head: Cast...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF High Pressure Filters type SF are designed for in-line hydraulic and lubrication applications, with a maximum operating pressure of 420 bar / 6.000 PSI. Used together with STAUFF SE series Filter Elements, a high efficiency of contaminant removal is assured. The high dirt-hold capacity of the elements ensures long service life and, as a result, reduced maintenance costs. Valves (available as an option) ▪ Bypass, reverse flow, non-return or multi-function valve Clogging Indicator ( available as an option ) ▪ Visual, electrical or visual-electrical differential pressure indicator Filter Elements ▪ Filter elements of SE series Construction ▪ High pressure filter designed for in-line assembly ▪ Threaded mounting holes on top and fluid ports on side ▪ Option of standard or two-part top loader version Operating Pressure ▪ Max. 420 bar / 6.000 PSI Nominal Flow Rate ▪ Max. 1.135 l/min / 300 US GPM Connections ▪ Option of BSP, NPT, SAE thread or SAE flange (ISO...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF manufactures one of the most comprehensive ranges of replacement filter elements for hydraulic and lubrication applications which are compatible with most of the common competitor products. The STAUFF Replacement Element Program includes replacement elements for over 10.000 part numbers covering almost every major international brands of filter elements. The majority of these are available from stock. Continuous improvement of the materials used as well as strict quality controls which take into consideration international standards guarantee the consistently high performance data of the filter elements. ▪ Innovative research, design and development ▪ Modern production lines with complete monitoring of production ▪ Certified work processes in accordance with: - ISO 9001:2008 (Quality management), - ISO 14001:2004 (Enviromental protection) - OHSAS 18001:2007 (Occupational health and safety) ▪ Comprehensive stocks and quick delivery ▪ Customised products in accordance with...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100% GORE-GFO ® e-PTFE-Fiber with Incorporated Graphite and Silicone Run-In Lubricant Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Characteristics Extremely wide range of applications for all kind of industries. Easy and safe installation and handling No ageing process Easy to disassemble Protection of shaft against wear (HRC 25) Superb heat conductivity Not recommended for abrasive media Operating range Pressure [p max]: 25 bar, Velocity [v max]: 25 m/s Pressure [p max]: 250 bar, Velocity [v max]: 2 m/s Pressure [p max]: 150 bar Temperature: t = -100… +280 °C pH: 0 - 14 Density: 1.50 g/cm³ Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Main application Centrifugal pumps Mixer Kneader Agitators Autoclave Refiner Vacuum pumps Suitable for Chemical industry Power plant technology Pulp and paper industry FOR INDUSTRIAL USE ONLY. Not for use in food, drug, cosmetic or...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Carbon Staple fiber with special Graphite Impregnation and silicon free Run In lubricant Practical useful application data: max. temperature: +200 °C Characteristics Volume stable, pressure stable High Cross section density due to special impregnation Excellent Value for money Graphitized all-round packing with Emergency run Capabilities Good wear resistance against abrasive and crystallizing products Recommended shaft surface hardness: HRC 45 Operating range Pressure [p max]: 20 bar, Velocity [v max]: 20 m/s Pressure [p max]: 250 bar, Velocity [v max]: 2 m/s Pressure [p max]: 150 bar Temperature: t = -50… +250 °C pH: 2 - 12 Density: 1.15 g/cm³ Practical useful application data: max. temperature: +200 °C Main application Centrifugal pumps Valves Mixer Kneader Agitators Suitable for Chemical industry Pulp and paper industry Waste water technology Community facilities Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Carbonized synthetic fiber with PTFE impregnation and run in lubricant Practical useful application data: max. temperature: +140 °C Characteristics Good flexibility Rot proof Form stable packing Good value for the money Recommended surface hardness HRC50 Operating range Pressure [p max]: 15 bar, Velocity [v max]: 15 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -50… +200 °C pH: 3 - 12 Density: 1.30 g/cm³ Practical useful application data: max. temperature: +140 °C Main application Centrifugal pumps Mixer Kneader Agitators Refiner Autoclave Gate valves Filter Suitable for Pulp and paper industry Sugar industry Waste water technology General maintenance Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special measurements. 04 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 - 25 mm on 5 kg spool Special length, pre-cut or die formed rings on request. 1 kg...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Carbonfiber with special impregnation and siliconfree dynamic high performance lubricant Practical useful application data: max. temperature: +250 °C max. pressure centrifugal pumps: 25 bar Characteristics Strong against abrasive mediums, yet low friction on shaft surface. Recommended shaft/sleeve hardness HRC 45 Volume stabile, minimal shrinkage, good heat conductivity Suitable as bullrings Operating range Pressure [p max]: 30 bar, Velocity [v max]: 25 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -50… +300 °C pH: 2 - 12 Density: 1.45 g/cm³ Practical useful application data: max. temperature: +250 °C max. pressure centrifugal pumps: 25 bar Main application Boilerfeed pumps Refiner Suitable for Chemical industry Pulp and paper industry Power plant technology Boiler houses Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special measurements. 04 - 09 mm on 1...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Combination Braid of ePTFE with incorporated Graphite and Polyimid Fiber with Run-In Lubricant Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Characteristics Combination braid with extended pH-range of 0 - 12 Improved heat conductivity and increased mechanical strength due to special material combination Reduced wear of the shaft surface. Recommended shaft surface hardness: HRC 35; Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 250 bar, Velocity [v max]: 2 m/s Pressure [p max]: 150 bar Temperature: t = -100… +280 °C pH: 0 - 12 Density: 1.50 g/cm³ Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Main application Centrifugal pumps Mixer Kneader Agitators Refiner Suitable for Chemical industry Chemical Sewage Universal use Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Combination Braid of ePTFE with Incorporated Graphite and Para-Aramid Fiber Surface reinforcement with Run-In Lubricant Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Characteristics Even and reduced shaft surface wear Excellent heat conductivity Recommended shaft surface hardness: HRC 45 Safe and universal packing with abrasive media Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 250 bar, Velocity [v max]: 2 m/s Pressure [p max]: 150 bar Temperature: t = -100… +280 °C pH: 2 - 12 Density: 1.45 g/cm³ Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Main application Centrifugal pumps Mixer Kneader Agitators Filter Refiner Suitable for Chemical industry Pulp and paper industry Waste water technology Variant S12K Plunger with Para-Aramid Cornerreinforcement, available 6 mm and above Form of delivery This packing can be manufactured from...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

PTFE-Graphite Fiber with Paraffin Run-In Lubricant Practical useful application data: max. temperature: +180 °C max. pressure centrifugal pumps: 20 bar Characteristics Special lubricating graphite minimizes friction and guarantees greater heat conductivity Shafts or shaft sleeves in HRC 25 recommended Universal PTFE/Graphite packing with good value for money Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 250 bar, Velocity [v max]: 2 m/s Pressure [p max]: 150 bar Temperature: t = -50… +280 °C pH: 0 - 14 Density: 1.65 g/cm³ Practical useful application data: max. temperature: +180 °C max. pressure centrifugal pumps: 20 bar Main application Centrifugal pumps Mixer Kneader Agitators Autoclave Refiner Gate valves Suitable for Chemical industry Power plant technology Pulp and paper industry General industries Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Polyimid Fiber with PTFE Impregnation and Silicone Run-In Lubricant Practical useful application data: max. temperature: +180 °C High fatigue strength and flexibility Good acid resistance High cross section density through PTFE blocking agent, good for crystallizing media Recommended shaft surface hardness: HRC 35 Good pliability, therefore perfect adaption of uneven shaft surfaces Operating range Pressure [p max]: 20 bar, Velocity [v max]: 15 m/s Pressure [p max]: 60 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -100… +280 °C pH: 0 - 12 Density: 1.30 g/cm³ Practical useful application data: max. temperature: +180 °C Main application Centrifugal pumps Mixer Kneader Agitators Filter Extruder Refiner Suitable for Chemical industry Sugar industry Pulp and paper industry Mining Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special measurements. 04 - 09 mm on 1 kg spool 10 - 15 mm on...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Synthetic Fiber with PTFE Impregnation and siliconfree dynamic Run in Lubricant Practical useful application data: max. temperature: +180 °C Characteristics High fatigue strength and flexibility Good acid resistance (e. g. hydrofluoric acid 15 % / 50 °C) High cross section density through PTFE blocking agent, good for crystallizing media Recommended shaft surface hardness: HRC 35 Good pliability, therefore perfect adaption of uneven shaft surfaces Operating range Pressure [p max]: 20 bar, Velocity [v max]: 15 m/s Pressure [p max]: 60 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -50… +280 °C pH: 1 - 13 Density: 1.35 g/cm³ Practical useful application data: max. temperature: +180 °C Main application Centrifugal pumps Mixer Kneader Agitators Filter Extruder Refiner Suitable for Chemical industry Sugar industry Pulp and paper industry Mining Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Para-Aramid Fiber Packing with PTFE Impregnation and Run-In Lubricant Practical useful application data: max. temperature: +200 °C Characteristics Volume stable, pressure stable High cross section density through PTFE blocking agent, safety against penetration of crystallizing media Offers excellent value for the money Good protection against wear, with abrasive and hardening media Recommended shaft surface hardness: HRC 50 Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -50… +250 °C pH: 2 - 12 Density: 1.20 g/cm³ Practical useful application data: max. temperature: +200 °C Main application Centrifugal pumps Mixer Agitators Autoclave Filter Refiner Kneader Paddle dryer Suitable for Pulp and paper industry Sugar industry Power plant technology Waste water technology Mining industry Variant Trapez shape TP7 P7A without lubricant for valves, armatures, gate valves S7G...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100 % Para-Aramid continuous Fiber with PTFE-Blocking Agent and Silicone free dynamic Run-In Lubricant Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Characteristics Excellent in highly abrasive products Wear resistent universal packing Minimized monitoring, short run-in period Shafts or shaft sleeves in HRC 60 recommended Operating range Pressure [p max]: 25 bar, Velocity [v max]: 25 m/s Pressure [p max]: 500 bar, Velocity [v max]: 1.5 m/s Pressure [p max]: 250 bar Temperature: t = -50… +280 °C pH: 2 - 12 Density: 1.25 g/cm³ Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Main application Centrifugal pumps Mixer Kneader Agitators Autoclave Refiner Suitable for All industries Chemical industry Waste water technology Pulp and paper industry Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special...

Request for a quote

HPM TECHNOLOGIE GMBH

Germany

Our Breeze technology has many enormous advantages over the previous classic lubrication applications. Discover enormous savings potential for mass production when using our LSJ Mini in your process. This system can be used optimally in the event of always consistent tool operations. For the machining process, an average of between 5 and 50 ml of lubricant is used per process hour and tool. These consumption values can also be briefly — depending on the requirements of the individual operation — increased to up to 200 ml per process hour. In addition to this excellent advantage over the previous method, the HPM Breeze method offers further enormous advantages from an economic and ecological point of view. • For optimum use with a cooling channel diameter of 0,9 mm² and up. • Manual adjustment of the pressure parameters • Optimally suited for consistent series processes with one parameter

Request for a quoteResults for

Lubricant application - Import exportNumber of results

46 ProductsCountries

Company type