- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- load stops

Results for

Load stops - Import export

ROLLON GMBH

Germany

“Lift and move” motion profile with multiple stations and long travel lengths. Synchronized movement system with hard anodized profiles. Polyamide nylon wheels with a rack and pinion system manage horizontal and vertical movement. Column modules carry out lifting movement via a recirculating ball screw drive. The column modules are operated with a single geared motor through a transmission with shafts and corner stops. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ELKON GMBH

Germany

The cement stored in the cement silos can be quickly discharged to the cement trailers (bulk carrier) by means of ELKON telescopic cement loading bellow. This system has a special structure with support legs allowing the bulk carrier parking under the discharge point and is equipped with a suitable bellow for feeding the material. ELKON telescopic cement loading bellow is equipped with level indicator to stop loading and lift up the bellow when it is in contact with the cement (material filling process is finalized). The bellow is also equipped with fan filter system to prevent powder during the material filling process. The system includes a control panel as well.

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The preferred field of application for the (gas) hydraulic industrial buffer (COMPENSER®) of the S-series is in the medium to heavy engineering industry sector. As a heavy duty shock absorber it is used in large crane systems (e.g. harbour crane, shipyard crane or container crane), metallurgical plants, rolling mills, loading systems or as end stop integrated in a rail buffer stop. Design & Function: The gas-filled inner tube 2 enters the outer tube 9. The damping medium flows from the pressure chamber 6 through the throttle orifices 8 of the metering tube 7 into the volume balance chamber 5. The separating piston 4 simultaneously moves in the direction of the impact cap 1 and compresses the nitrogen gas filling. In the gas space 3, the energy is stored which is required for the reset of the inner tube. When the inner tube 2 returns to the initial position, the separating piston 4 moves in the opposite direction and presses the damping medium back into the pressure chamber 6.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

In the aircargo industry, lift platforms are used as lifting devices for large loads under rough ambient conditions, i.e. in airfreight systems. Especially for cargo clearance processes at airports or hauliers, safety and reliability are paramount. This is why LAWECO lifting solutions based on the proven scissor lift tables are used world wide to overcome differences in height. LAWECO with its decades of experience and innovative lifting technology is a partner for efficient cargo handling in the future, especially where extraordinary tasks have to be solved. 10 feet workstation incl. load cells and fixed stops in front of the running rollers. Used to pack or unpack aircargon container or pallets. Dimension: 3200 x 2200 mm Operating stroke: 2100 mmm Rated load: 7000 kg

Request for a quote

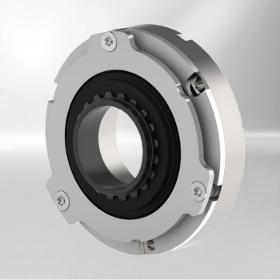

KENDRION (VILLINGEN) GMBH

Germany

The spring-applied brakes which are ideally suited for robotics is designed for robotics solutions and loads of up to appr. 20 kg, but it can also be used in other applications requiring small geometrical dimensions. With regard to their power density the slim single-disc brakes are flatter and lighter than the market standard, and due to their large inner diameter they are well suited for hollow-shaft drives. This makes them perfect for applications in lightweight robots with integrated drives. There is a growing demand for safety technology in order to avoid injuries by collisions, especially if the control technology or even the power supply fails. In this case electromagnetic brakes are usually the method of choice. As safety brakes they bring moving masses to a stop, keep loads in position and therefore prevent humans and material assets from being affected.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NORIS GROUP GMBH

Germany

NORISYNC 4 is our new power management system (PMS) and optimises the generation and use of electricity. Core of the system is the new power management controller NORISYS 4 PMC. It is based on our open automation platform NORISYS 4 that was especially developed to automate marine applications. As a customised solution, NORISYNC 4 efficiently manage the power distribution, load depending start and stops of diesel generators, the load sharing, synchronising the generator set power and also the use of the energy storage system (ESS) of hybrid and fully electric propulsion systems. CPU based multi-master system for flexible system scalability Safety through redundant communication Different operation modes Easy system configuration Intelligent control of energy storage systems Standardised interfaces to higher level systems Remote access for maintenance and service Approvals in preparation: BV, DNV-GL, LR

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The MaxxReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions. Construction MaxxReach Telescopic Boom Conveyors are built to the highest standard with a 10mm thick main case providing one of the strongest, most robust, conveyors of its type on the market. Boom End Lights Two low energy powered LED units are fitted to the front of the conveyor to provide light directly in front of the loading area. Extension Stop Bar A springloaded bar is fitted to the front of the telescopic boom conveyor and it acts as a failsafe stop when the conveyor is extending. If activated, the boom conveyor will stop all functions.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

The BestReach Telescopic Boom Conveyor will transport items quickly, safely and efficiently by extending directly into the trailer without the need for support. The use of this unit will reduce load/unload times significantly whilst improving operator working conditions. Construction BestReach Telescopic Boom Conveyors are built to the highest standard with a 10mm thick main case providing one of the strongest, most robust, conveyors of its type on the market. Boom End Lights Two low energy powered LED units are fitted to the front of the conveyor to provide light directly in front of the loading area. Extension Stop Bar A springloaded bar is fitted to the front of the telescopic boom conveyor and it acts as a failsafe stop when the conveyor is extending. If activated, the boom conveyor will stop all functions.

Request for a quoteResults for

Load stops - Import exportNumber of results

9 ProductsCountries

Company type