- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- linear motors

Results for

Linear motors - Import export

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

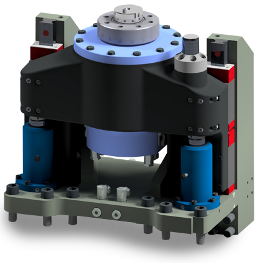

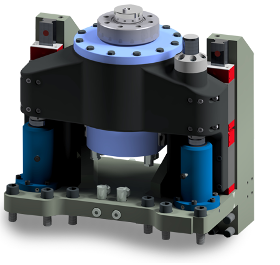

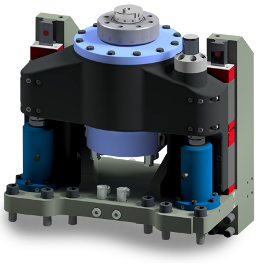

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

IGUS® GMBH

Germany

drylin® SAW-1040 linear module, drylin® W aluminium profile, surface: hard-anodised, Trapezoidal lead screw TR10x2, machined lead screw end 69x15mm, guide carriage, aluminium shaft end support. Stroke length: 500mm, carriage length: 69mm, NEMA23 stepper motor with JST connector. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

IGUS® GMBH

Germany

Lightning fast opening and closing with Zipper E-Chain® und E-Tubes - Zipper E-Chain® satisfy by their practicability and performance. The "zip fastening" function shortens the installation time. The small pitch, the rugged elastic zipper band and the heavy duty links amaze in high accelerations. The Zipper series is one of the most popular igus® E-Chain® series in the sophisticated industrial sectors. Other information Series 047 Inner height hi: 9 mm Inner widths Bi: 10 - 16 mm bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, rip-open along the outer radius Series 07 Inner height hi: 10,3 mm Inner widths Bi: 6 - 64 mm bending radii R: 18 - 48 mm Pitch: 20 mm E-Chain®, rip-open along the outer radius Series 09 Inner height hi: 15 mm Inner widths Bi: 10 - 50 mm bending radii R: 28 - 48 mm Pitch: 20 mm E-Chain®, rip-open along the outer radius Series 15 Inner height hi: 17 mm Inner widths Bi: 15 - 100 mm bending radii R: 38 - 180 mm Pitch: 30,5 mm E-Chain®, rip-open along the outer radius Series 17 Inner height hi: 32 mm Inner widths Bi: 15 - 100 mm bending radii R: 63 - 125 mm Pitch: 30,5 mm E-Chain®, rip-open along the outer radius Series R07 Inner height hi: 10,3 mm Inner widths Bi: 10 - 50 mm bending radii R: 38 - 48 mm Pitch: 20 mm E-Tube, rip-open along the outer radius Series R09 Inner height hi: 15 mm Inner widths Bi: 10 - 50 mm bending radii R: 48 - 100 mm Pitch: 20 mm E-Tube, rip-open along the outer radius Series R15 Inner height hi: 17 mm Inner widths Bi: 25 - 80 mm bending radii R: 63 - 180 mm Pitch: 30,5 mm E-Tube, rip-open along the outer radius Series R17 Inner height hi: 32 mm Inner widths Bi: 15 - 63 mm bending radii R: 63 - 125 mm Pitch: 30,5 mm E-Tube, rip-open along the outer radius Clean room Class 1 (ISO class 3) for Series 15, tested by the Dryden Engineering Company, California. iF-Design-Award for Zipper-Design UL94-V0 classification on request 58 dB(A) determined at the igus® laboratory, v = 1.0 m/s unsupported, Series 09.50.028.0 Lightning fast opening and closing with Zipper E-Chain® und E-Tubes - Zipper E-Chain® satisfy by their practicability and performance. The "zip fastening" function shortens the installation time. The small pitch, the rugged elastic zipper band and the heavy duty links amaze in high accelerations. The Zipper series is one of the most popular igus® E-Chain® series in the sophisticated industrial sectors. Series 047 Inner height hi: 9 mm Inner widths Bi: 10 - 16 mm bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, rip-open along the outer radius Series 07 Inner height hi: 10,3 mm Inner widths Bi: 6 - 64 mm bending radii R: 18 - 48 mm Pitch: 20 mm E-Chain®, rip-open along the outer radius Series 09 Inner height hi: 15 mm Inner widths Bi: 10 - 50 mm bending radii R: 28 - 48 mm Pitch: 20 mm E-Chain®, rip-open along the outer radius Series 15 Inner height hi: 17 mm Inner widths Bi: 15 - 100 mm bending radii R: 38 - 180 mm Pitch: 30,5 mm E-Chain®, rip-open along the outer radius Series 17 Inner height hi: 32 mm Inner widths Bi: 15 - 100 mm bending radii R: 63 - 125 mm Pitch: 30,5 mm E-Chain®, rip-open along the outer radius Series R07 Inner height hi: 10,3 mm Inner widths Bi: 10 - 50 mm bending radii R: 38 - 48 mm Pitch: 20 mm E-Tube, rip-open along the outer radius Series R09 Inner height hi: 15 mm Inner widths Bi: 10 - 50 mm bending radii R: 48 - 100 mm Pitch: 20 mm E-Tube, rip-open along the outer radius Series R15 Inner height hi: 17 mm Inner widths Bi: 25 - 80 mm bending radii R: 63 - 180 mm Pitch: 30,5 mm E-Tube, rip-open along the outer radius Series R17 Inner height hi: 32 mm Inner widths Bi: 15 - 63 mm bending radii R: 63 - 125 mm Pitch: 30,5 mm E-Tube, rip-open along the outer radius E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining and separating of the Zipper E-Chain®. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. Zipper Zipper E-Chain® Short installation time: Lightning fast opening and closing of lids with zipper Zipper lid can be separated and joined in any chain link Small pitch for low-noise, silent operation High accelerations: 100 m/s² and more Interior separation possible Zipper E-Tube resistant against chips and dirt Closed E-Tube with zip-open system Protection against dirt and chips Lightning fast opening of the lid in a band Modular design - simple lengthening and shortening Small division for low-noise, silent operation, high accelerations Typical industrial sectors and applications Automatic insertion machines Semiconductor devices Linear motors, handling systems Any kind of technical equipment Measuring instruments Machine tools (Zipper E-tube) Clean room Class 1 (ISO class 3) for Series 15, tested by the Dryden Engineering Company, California. iF-Design-Award for Zipper-Design UL94-V0 classification on request 58 dB(A) determined at the igus® laboratory, v = 1.0 m/s unsupported, Series 09.50.028.0

Request for a quote

IGUS® GMBH

Germany

DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv DryLin® N - Technical data DryLin® linear guide systems in the cleanroom DryLin® N - Applications DryLin® N - Design rules System selection & service life calculation NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. DryLin® N - Low profile linear guide system NK-02-17 DryLin® N - Low profile linear guide system NK-22-17-40 drylin® N - Low profile linear guide system NK-22-17-30 NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor DryLin® N low profile guide systems offer you low profiles in various widths. Like in all drylin® products, the carriage runs without lubrication in anodized aluminum profiles. The material used and the unique design make DryLin® N a cost-efficient and flexible guide system. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Rail made of anodized aluminum 2 Gliding elements made of iglidur® J or J200 3 Carriage made of chromated zinc or plastic 4 Carriage with threaded hole or through hole Advantages: Small installation height between 6 and 12 mm Lightweight Numerous carriage options – also with pretension Maintenance-free, self lubricating Corrossion-resistant Low wear with low coefficient of friction Rails in silver or black anodized When not to use ? When precision below 50 μ is required In high loads over 50 kg drylin® T drylin® R drylin® W When high resistance to chemicals is required drylin® W drylin® R DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv Standard, preload and floating bearing NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. 1. NW-01-27 standard 01 with through hole g 2. NW-02-27 standard 02 with threaded hole 3. Preload with through-hole or threaded hole 4. uinjection-molded with through-hole or threaded hole 5. NW-21-27-60P Vollkunststoffschlitten mit Durchgangsbohrung 6. NW-22-27-60P solid polymer carriage with through hole 7. NW-11-27-80 double carriage with through hole NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 1. Standard 02 with threaded hole 2. Injection-molded with threaded hole 3. Standard 01 with through hole NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P 1. Standard 02 with mounting nuts 2. Injection-molded with mounting nuts NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor

Request for a quote

FÖHRENBACH GMBH

Germany

The highest accuracy class “Ultra-Precision plus” impresses with an accuracy of 0.0005 mm, thus 0.5 µm. Due to the fact that the control unit of the Föhrenbach slides is compatible with the interfaces of almost all measuring systems, this extraordinary repeatability does not depend on a particular system or a specific provider. Föhrenbach profiled guide slides with integrated linear motor are available in the series PFL (with bellows covers) and PCL (with sheet metal covers). For both series three sizes are available. We developed three resp. two linear motors of different force.

Request for a quote

MAGNESCALE EUROPE GMBH

Germany

The BH25 is a high resolution exposed linear encoder with interferometric measurement signal generation. The BH25 scale has a graduation period of 1µm. The interferometric laser scale principle generates a sinusoidal measurement signal with a signal period of 250nm in the read head. The BH25 is characterized by its small size and high signal quality. It is suitable for resolutions of up to 3.8pm. Due to the reflective scanning and the small design it is perfectly suited for high accuracy X/Y stages with linear motor drive as well as for measurement applications

Request for a quote

FRANKE GMBH

Germany

Franke FDH linear guides are suitable for linear movement tasks, especially in dynamic pick-&-place applications. They have rollers with angular contact ball bearings for the highest acceleration and speed values, for example when using linear motors as the drive source. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

Request for a quote

FRANKE GMBH

Germany

Franke FDH linear guides are suitable for linear movement tasks, especially in dynamic pick-&-place applications. They have rollers with angular contact ball bearings for the highest acceleration and speed values, for example when using linear motors as the drive source. Rail elements can be manufactured in lengths from 200 mm to 4000 mm and can be coupled endlessly.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

Traverse path: 800 x 900 x 600 A axle ± 140° C – axle 360° (endless) High precision machining centre in gantry construction All axles are double-equipped with motor and linear scales Zero point clamping system

Request for a quote

WIGTEC FISCHEREDER KG

Germany

Traverse path: 1250 x 1250 x 870 A axle ± 140° C – axle 360° (endless) High precision machining centre in gantry construction All axles are double-equipped with motor and linear scales Rotary axles are driven by torque motors Zero point clamping system

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 2400 is a fully automated, linear motor driven, filling, foil application, foil sealing and capping machine, suitable for creamy to liquid filling media. Capacity: 35-40 pcs per minute Available versions: Fill/Seal, Fill/Cap, Seal/Cap, Fill/Seal/Cap machine frame from aluminium profile indexing transport system for jars horizontally working conveyor for jar infeed and discharge position control for jars in indexing rotary transport dosing pump from 1.4404 10 l hopper with level control filling nozzles driven by LinMot-e-motor pick and place system for pre-cut foils from magazines driven by LinMot-e-motor 1 spot sealer to fix the foil at the sealing rim of the jars sealing system with conduction sealing head capping station with LinMot-e-motor infeed conveyor for caps electric cabinet with operation panel manual central lubrication system safety doors with aluminium profile frame and windows from makrolon

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

In principle, in the parallel arrangement, the vertically aligned rotary drive axis (swivel motor) is placed next to the linear drive axis, which is also vertically aligned and preferably consists of two linear cylinders. The swivel motor is inserted and lifted in a motor support mounted separately in linear guides. The pallet holder is mounted directly on the shaft of the swivel motor or in a separate pivot bearing in the motor support. Tilting moments caused by large asymmetrical loading conditions are thus safely absorbed. We offer customized solutions for various applications. Our qualified team will be happy to advise you.

Request for a quote

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

WiTEC Performance is the perfect solution for the most precise and fastest machining of your sheet material! The Performance is the flagship solution of the WiTEC machine family. A machine concept based on a FEM optimized design, built using premier precision components, and equipped with linear magnet motor technology, the Performance is able to achieve the highest levels of precision and speed, up to 80m/min! Thanks to the combination of Wissner’s innovative and patented hold&press Technology and sophisticated Vacuum System, you can mill even the smallest parts all the way through the finishing cut-out! No need for any adhesive paper or foil, no need for leaving connector tabs, and no deburring or cleaning is necessary! The ready-finished parts will go directly from the machine table to the end customer!

Request for a quote

NANOSYSTEC GMBH

Germany

The work area of 700 x 900 mm offers sufficient space. The motion system works with linear motors and linear optical encoders which guarantee extremely high resolution and precision – even at the high speed due to the excellent acceleration of the linear motors. The empty surface of the vertical stage is equipped with an interface for fast tool changing. Sensors measure the force applied by the tools to the device. The desired forces can be programmed so that each device is handled ideally.Eutectic bonding is performed with high energy laser radiation and with a wavelength matched to the device. Temperature sensors transmit the values to the control electronics and the power is precisely adapted. In this way, the temperature follows the desired profile fast and accurately. NanoBond utilizes precision dispensers for gluing processes. These instruments apply a volume from nanoliters to several milliliters. In most application

Request for a quoteResults for

Linear motors - Import exportNumber of results

36 ProductsCountries

Company type

Category

- Electric motors and parts (18)

- Machine tools, metal machining - parts and accessories (3)

- Bearings - ball, needle and roller (2)

- Adjustment - machine tools (2)

- Vacuum cleaners - industrial (2)

- Import-export - electrical and electronic equipment (1)

- Milling - machine tools (1)

- Package stamping machinery (1)

- Packing and packaging - machinery and equipment (1)

- Precision measuring instruments (1)

- Robotics (1)

- Slide production (1)