- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- lifting table

Results for

Lifting table - Import export

GSW SCHWABE AG

Germany

A stationary production aid everywhere where bigger loads have to be lifted or lowered, e.g. as loading table behind compact feed lines Stroke from 800 1600 mm Electrohydraulically driven lifting and lowering, controlled via hand sensor device (Totmann) on a 3m cable.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

LAWECO lift platforms are mainly used for rationally stacking and destacking wood up to a stack weight of 120 tons. Additional typical applications include overcoming height differences as well as rapid raising and lowering of individual pallets. In use with a two-floor magazine

Request for a quote

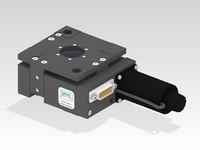

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

The high-accuracy lift tables (stages) are used where elements have to be positioned with high accuracy. With flexible adaptor plates, they fit seamlessly into UHL's modular component system. With recurring assembly dimensions, the lift tables likewise the rotary and swivel stages allow diversification when combining with other UHL's positioning systems. Backlash-free pre-loaded roll bearing guarantees a high sequence accuracy. A stepper motor and multiple threads (HT4) or 2 opposed-running wedges (HT7) are used as standard drive for the stroke. Mounting bore holes are available for the assembly of holding fixtures in the upper plate.

Request for a quote

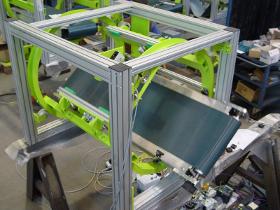

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

DAMBACH lift tables are efficient transfer units for mergers, crossings or branches in flows of materials. Roller or chain conveyors can be integrated as required. The interlocking lift mechanism combined with a rigid frame protects the unit loads and ensures optimum availability. As an option, variable intermediate lift positions can be included to ensure greater flexibility. The compact dimensions and safety guards expand the range of applications. Turntable with Roller or Chain Conveyor Turntables can divide or merge flows of materials without changing the orientation of the unit loads. The highly dynamic turntable drives from DAMBACH are interlocking units and ensure precise rotational angles of up to 270° with any number of intermediate stops. For optimum occupational safety, our turntables can be fully enclosed. In addition, the innovative modular design guarantees numerous and diverse applications and ease of servicing at the same time.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Lifting height up to 1,800 mm Load capacity up to 6000 kg The lifting tables in the Middle Class are available in any preferred size. Thanks to the modular design (base frame, scissor arms, hydraulic unit, platform sizes and options) they can be easily adapted to individual needs, taking into consideration also characteristics of loading/unloading areas. Benefits Infinitely variable hydraulic height adjustment Extensive project know-how Production according to German quality standards

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Lifting height up to 12,500 mm Load capacity up to 100 t To bridge variable levels and for very heavy loads, we have developed highly effective solutions in the form of our Giant series of Lorry Lifts. These Lorry Lifts are designed for loads weighing up to 100 t and elevations of up to 15 m. The Giant HS 20 is capable of raising or lowering an entire truck of up to 20 m in length to the desired loading level. Benefits Platforms for all conventional types of truck Customer-specific superstructures Save time by conveying straight to the desired level Save space with the scissor lift platform instead of a ramp Compliant with the EU Machinery Directive 2006/42/EC Compliant with DIN EN 81-2 (on request)

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Space-saving parking of one or two cars Park the car on the platform and let it magically disappear in a pit The car scissor lift VERTICAR from Lödige is a perfect solution for parking one or two cars in a very confined space. A significant advantage of VERTICAR is minimum space requirement. This is successfully achieved through the integration of the machine into a pit. Thanks to an overhead canopy, a flat and even surface is provided and the lifting table, i.e. the parking position is fully covered. As a result a vehicle is parked in a pit and the overhead surface remains completely intact. Furthermore, as it requires a low installation height, a classic shaft is not necessary. Benefits of the car scissor lift Saves on construction space as a ramp is not required Creates two car parking spaces in even the tightest locations Safe operation with fingertip control Bio-oil used to protect the environment

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Precision handling for heavy loads From end-of-line, through rack handling, to automated storage: Lödige has complete control of all the materials handling processes required in the press shop — including tool handling and systems for improved tool maintenance. Your advantages using Lödige solutions in the press shop: Ergonomic tool maintenance Coil handling up to 40 t Safe provision of pressed components Lifting and tilting tables up to 40 t Connection to pressed component storage Linked materials handling systems

Request for a quote

IGUS® GMBH

Germany

drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The latest development in lifting platform technology is based on mechanical drive technology using belts. Hydraulic oil is not required. Due to a patented catch system, BELT-LINE meets the safety requirements laid down in DIN EN 1570. The combination of exemplary positioning accuracy, smooth running and long service life is the reason the BELT-LINE is an economical precision solution, and not only for sensitive areas. Exemplary smooth running BELT-LINE convinces with a low noise and harmonious movement sequence, paired with maximum lifting speed and positioning precision. Minimum maintenance time and costs without hydraulic oil In particular in sensitive areas, the robust BELT-LINE technology with its long operating life is the best possible solution. The low-wear components can be quickly replaced due to the modular design. Excellent load change behaviour In the design phase, particular emphasis was placed on developing an excellent load change behaviour. The resilient suspension behaviour is only surpassed by LAWECO push-chain lift platforms.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

LAWECO lift platforms are mainly used for rationally stacking and destacking wood up to a stack weight of 120 tons. Additional typical applications include overcoming height differences as well as rapid raising and lowering of individual pallets. for double-sided feeding

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The predominant use of LAWECO lifting platforms in the paper industry is for the formation and separation of stacks. Additional application possibilities are the handling of paper rolls and rack loading. Movable lifting table to feed a printing machine with foil material. Dimension: 1700 x 840 mm Operating stroke: 700 mmm Rated load: 2500 kg

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The predominant use of LAWECO lifting platforms in the paper industry is for the formation and separation of stacks. Additional application possibilities are the handling of paper rolls and rack loading. Lifting table to load and unload storage carts for printing cylinders incl. control station for operator. Dimension: 5350 x 2500 mm Operating stroke: 2850 mmm Rated load: 2500 kg

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

LAWECO lift platforms are mainly used for rationally stacking and destacking wood up to a stack weight of 120 tons. Additional typical applications include overcoming height differences as well as rapid raising and lowering of individual pallets. With a hydraulically driven deposit device

Request for a quote

GSW SCHWABE AG

Germany

Moving solutions for all who need to transport or lift an object but have no fork lift or crane available Our Lift Trolleys, Lift Tables and Box Tilters will not let you down.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The predominant use of LAWECO lifting platforms in the paper industry is for the formation and separation of stacks. Additional application possibilities are the handling of paper rolls and rack loading. Lifting table with automatic ejecting device for paper rolls Dimension: 2700 x 750 mm Operating stroke: 1750 mmm Rated load: 5000 kg

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

In the aircargo industry, lift platforms are used as lifting devices for large loads under rough ambient conditions, i.e. in airfreight systems. Especially for cargo clearance processes at airports or hauliers, safety and reliability are paramount. This is why LAWECO lifting solutions based on the proven scissor lift tables are used world wide to overcome differences in height. LAWECO with its decades of experience and innovative lifting technology is a partner for efficient cargo handling in the future, especially where extraordinary tasks have to be solved. To handle air cargo container or pallets including adjustable driven ram protection, walkways, a winch and hydraulic side-shift function. Dimension: 830 x 4230 mm Operating stroke: 1200 mmm Rated load: 14000 kg

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

In the aircargo industry, lift platforms are used as lifting devices for large loads under rough ambient conditions, i.e. in airfreight systems. Especially for cargo clearance processes at airports or hauliers, safety and reliability are paramount. This is why LAWECO lifting solutions based on the proven scissor lift tables are used world wide to overcome differences in height. LAWECO with its decades of experience and innovative lifting technology is a partner for efficient cargo handling in the future, especially where extraordinary tasks have to be solved. 10 feet workstation incl. load cells and fixed stops in front of the running rollers. Used to pack or unpack aircargon container or pallets. Dimension: 3200 x 2200 mm Operating stroke: 2100 mmm Rated load: 7000 kg

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Working range Blind rivet nuts from M3* up to M6 alu and up to M5 steel, brass and stainless steel Technical data Weight: 600 g Total length: 260 mm Stroke: 7 mm Accessories Standard: Threaded mandrel and nosepiece M5 (optional also with M4 or M6) Maintenance instructions with spare parts list Stroke table Features • Simple lift setting via a knurled nut for safe and complete setting of the blind rivet nuts • Threaded mandrel protection via spring ring for fast tool-free replacement of the threaded mandrel • With opening spring for simple handling • Body in high-quality die cast aluminium • Body head made of forged chrome-vanadium steel • Ergonomic handles

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

anti-backlash pre-loaded rolling bearing for high accuracy different assembly bore holes in the lifted plate for devices and holding fixtures

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

We provide a wide range of precise high valuable accuracy classified linear stages, open or closed frame XY stages, micropositioning elements and rotary or lift tables. Closed loop operation is supported by using optional steel or glas linear scales or rotary encoders. Standard stands in grey iron cast or granite are available additionally. The positioning systems can be driven by high resolution 1-, 2- or 3-axis motion controllers with joystick and RS232/USB/LAN interface.

Request for a quote

ALPHA LASER GMBH

Germany

This stable work table can be used with laser sources from 300 - 900 W, which are integrated in the work table. The modular design allows the use of various optics and focal lengths, so that you can optimally carry out your tasks. The system can be operated either manually - with our instantly responding joystick - and semi-automatically or automatically with the WINLaserNC software. When welding, workpieces are moved precisely on the three axes of movement of the work table. An axis of rotation is also available. The Z axis of the table lifts workpieces up to 450 kg. The laser and motion system are conveniently operated via the control console with an intuitive touchscreen. With the AL-TW you can weld without restricting the work area. This enables the processing of large workpieces. We support you with the implementation of the laser safety measures with our laser safety concept.

Request for a quote

SCHMITZ U. SÖHNE GMBH & CO. KG

Germany

Even the underside of the DIAMOND operating table, so often a critical issue from the point of view of hygiene, can be conveniently cleaned by means of the cleaning shuttle: The DIAMOND Operating table is moved into the device with the table top in its highest position,the frame of the cleaning shuttle is positioned under the seat section of the table. Lowering the table top then lifts the table base off the floor and gives access to its underside for cleaning.

Request for a quote

SIM AUTOMATION GMBH

Germany

Entire system solution from a single source: — from construction of the laser cell to integration of your chosen KEYENCE laser — self-contained and high-performance solutions for laser labeling small batches of individual parts SIM-Marker Mini Equipment options: Standard version — Manual setting of the focal point with mechanical lift table — Door opening by hand — Connection to PC via LAN or USB — Set up: directly on a desk or mounted onto the movable base frame — Latest three-axis laser marking systems offers a laser labeling system that can be precisely adjusted to the materials and part geometries that shall be labeled Advantages of integrated optical three-axis technology: — focal point to be freely set and is especially impressive — mark on any shape with outstanding sharpness, including on slanted surfaces, cylinders and cones Size of the labeling field: between 120 x 120 mm and 330 x 330 mm.

Request for a quote

KLN ULTRASCHALL AG

Germany

The LVW series covers smaller applications with machines of approx. 500 mm width and large applications up to a width of 2000 mm, like pallets, bumpers and more. As a principle our standard machines are equipped with an hydraulic lifting table. Depending on the machine size a contact force of up to 70 kN can be applied. This is necessary for large suction pipes made of PA 6.6 GV30 with heavy distortion or very large welding surfaces. Our vibration welders are fitted with our patented CPC system. This kind of regulation which is integrated in the converter stimulates the vibration unit with optimal resonance frequency. A low energy consumption is guaranteed during the friction phase. It is not necessary to enter the frequency parameter in the machine, as it is permanently “optimized”. This, the KLN drive systems are independent from the tool weight. The tool weight is solely limited in height, caused by the mechanical design and the high accelerating powers arising in these systems.

Request for a quote

FATH GMBH

Germany

Lift castor system for a fast and flexible placing of plant and machinery or assembly tables; gear transmission ratio: 10:1 Max. Load: 500 kg per lifting unit Material: Housing: Die-cast aluminum with PTFE bearing Roller: Plastics PA with ball bearing Roller housing: Zinc plated steel Set: 4 lifting units 1 hydraulic drive unit 4 hydraulic pipes at each 3 m, pre-filled Extras: Other sets on request

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Oswald Metzen, a METZEN Industries’ brand, is specialised in conveyor technology. We provide you with everything you need under one roof: from planning to production and assembly of our innovative, custom conveyor technology which meets the highest quality requirements. Our conveyor systems portfolio: Screw conveyors Construction of silos, containers and their dispensers Belt conveyors Link conveyors Roller conveyors Rotary tables Bucket lifts Two-shaft shredders Big bag systems Transfer lines/return conveyors with inclined lifts Turning stations Transfer devices Pallet conveyors/changers Interlinking systems Chip conveyors We apply our senior engineers’ expertise in the latest technology and our certified welders’, fitters’, steelworkers’ and electricians’ years of experience to our work in our high-tech manufacturing centres and in your plant. We create in-house or externally designed components and systems. We can step in if you require short-term

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description Workpiece support Indexing table unit 360x1° / no lifting off NC special indexing table SDV-NC3.5/3H and NC thrust bearing - Duplex-worm gear i=85 with i=5 with belt drive - Division 360x1° - with hydraulic locking, indexing table 1,350 Nm, incl. thrust bearing 2,050 Nm Special charateristics: - 3 channel media supply from below (device tensioning, release, blast air) - Media supply from top, Hirth-ring tensioning, release, sealing air, hydraulic clamping

Request for a quoteResults for

Lifting table - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Lifts and escalators (14)

- Goods lifts (4)

- Lifting - vehicles (4)

- Lifts (4)

- Measurement - Equipment & Instruments (3)

- Conveyor systems (2)

- Machine tools, metal shaping - parts and accessories (2)

- Lifting equipment (1)

- Automation - systems and equipment (1)

- Car lifts for garages (1)

- Laser - cutting and welding machines (1)

- Rivets (1)

- Storage equipment and systems (1)

- Surgical apparatus and equipment (1)

- Welding, plastics - machinery (1)