- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- leak testing systems

Results for

Leak testing systems - Import export

INFICON GMBH

Germany

The Sensistor ILS500 is a fully integrated leak testing system that controls tooling, tracer gas handling, test sequencing and leak testing — all behind an easy to use color touch screen display. The compact instrument helps you get a fast start for your leak testing by guiding you through the setting of parameters. It controls the gas handling so that you have gas at the right time, the right place and at the right pressure. It makes a gross leak test before spending any tracer gas unnecessarily and also assures that the used tracer gas is evacuated after the test. The tooling in your fixture is controlled by the ILS500, and the complete system is able to execute orders from a PLC or other type of computer. With the dual probe possibility, you are even able to first leak test an object with the automatic probe and immediately thereafter do leak locating with the hand probe. The Sensistor ILS500 is the perfect system for solutions ranging from manual sniffing to being a key...

Request for a quote

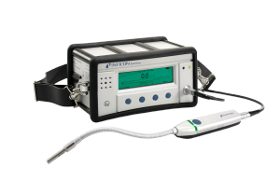

INFICON GMBH

Germany

The portable Extrima Leak Detector is the ultimate intrinsically safe instrument for leak detection in the toughest environments, including hazardous locations such as Zone 0 (corresponding to Division 1). The Extrima allows you to quickly find leaks on a wide range of industrial applications such as aircraft and hydrogen cooled generators. With the Extrima the aviation industry has a safe, accurate and yet simple solution for leak testing of complete fuel systems, both in production and maintenance situations. Thanks to its high sensitivity, the Extrima can detect even minute leaks with pinpoint accuracy. Extensive tests have shown that using the Extrima can reduce the average time by more than 50 % for identifying, locating and repairing a leak on a fighter jet during maintenance. Click here to see how easy it is to find leaks on aircraft fuel system using the Extrima (video 3:55, YouTube). It is certified for use in Zone 0, classification Ex ia, IIC T3 with ATEX, IECEx,...

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

In order to ensure that castings, valves, pumps, hoses and other components or groups have been manufactured free of leakage, they are tested in non-destructive leakage tests. Oxygen, air, nitrogen or sulfur hexafluoride (SF6) can be used as the test medium.

Request for a quote

CETA TESTSYSTEME GMBH

Germany

The CETATEST XS is a compact, fully automatic leak tester for the detection of leaking parts within the cycle time of the production process. The tester is designed for leak testing of small-volume test parts and short total testing times. It is equipped with a gauge pressure sensor, through which the leak-related pressure decay is detected during the measurement time (relative pressure method). Using the application software CETA Soft XS the parameterisation of the test programs is carried out. Measurement results and pressure variation curves can be recorded. Typical applications: Leak tests which require a large measuring range.

Request for a quote

CETA TESTSYSTEME GMBH

Germany

The CETATEST 715 series includes fully automatic working leak tester for the detection of untight parts within the cycle time of the production process. The leak tester uses a gauge pressure sensor and has a large measurement range. Therefore the CETATEST 715 is especially qualified for the simple testing of parts with large leakages, as they occur in the testing of valves. The test types "sealed component" and "dynamic pressure" can also be integrated. Typical applications: Testing of sanitary fittings, plastic welds, check valves Operating methods: Single-channel operation, two-channel operation The measurements in two-channel operation are synchronous. Measurement ranges: Max. +/-10,000 Pa Result units: Pa, hPa, PSI, Pa/s, hPa/s, mbar*l/s, ml/min, ml/h, l/min, l/h, mmHg, mmWs, Torr Pressure ranges: -1 bar, 200 mbar, 1 bar, 6 bar, 10 bar, 16 bar, 20 bar, negative gauge pressure and positive gauge pressure ranges can be combined.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CETA TESTSYSTEME GMBH

Germany

Pressure ranges: -1 bar, +/- 5 mbar, +/- 50 mbar, 200 mbar, 1 bar, 6 bar, 10 bar, 20 bar, 30 bar, 400 bar (high pressure version), negative and positive gauge pressure ranges can be combined. Measuring ranges: ± 500 Pa / ± 5,000 Pa (display resolution: 1 Pa, internal resolution: effectively 0.01 Pa) Result units: Pa, hPa, PSI, Pa/s, hPa/s, mbar • l/s, ml/min, ml/h, l/min, l/h, mmHg, mmWs, Torr Types of test: Standard: Pressure decay Optional: sealed component, dynamic pressure measurement, pressure steps, pressure rise (with double leak connector) Parameters can be exported to a USB stick or imported again. The storage of measurement series and waveforms is possible. Interfaces: Standard: Digital I / O, RS-232 Optional: Profibus DP, Profinet, Ethernet, EtherCAT, Bluetooth, USB Dimensions: 345 mm x 145 mm x 435 mm (W x H x D) In the high-pressure version, leak tests up to a test pressure of 400 bar can be carried out according to the pressure rise method.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

Package Leak Detection system using a water-based bubble test. LEAK-MASTER® EASY allows the detection even of the smallest of leaks. After the package is placed into the chamber filled with water, the head space above the water level is evacuated using a venturi vacuum (compressed-air) system. This causes the package immersed in the water to inflate, allowing any leaks and their location to be identified by a stream of bubbles. Benefits: economical and uncomplicated visual inspection allows localisation of the leak for all flexible and rigid kinds of packaging (food-, pharmaceutical-, industrial- and other packaging) short testing period (< 30 sec.) easy-to-use intuitive operation – no special skills required easy installation and start-up no trace gas required in package can also be used for altitude simulation optionally also for vacuum packaging, set order-No. 956992700 no calibration required various chamber sizes avail

Request for a quoteResults for

Leak testing systems - Import exportNumber of results

8 ProductsCountries

Company type