- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser lines

Results for

Laser lines - Import export

QUELLTECH GMBH

Germany

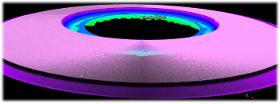

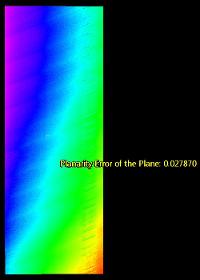

Particular Challenge: For the assessment of rotating parts, numerous parameters have to be taken into consideration: Concentricity, radial run-out and axial run-out (i.e. wobble); furthermore thickness, diameter, planarity and the absence of surface defects had to be examined. The solution developed by QuellTech consists in a configuration of three Q6 Laser Laser Scanners.Each of the lateral surfaces is assigned to its own scanner. In order to enable the thickness precisely to be determined, both laser lines are mutually oriented in opposite direction. The third scanner inspects the outer circumference of the wheel, this way measuring diameter and radial run-out. All of these scanners are subject to encoder signals supplied by the rotary axis and synchronously triggered, so possible defects on the wheel can precisely be localized. The measurement takes place at a resolution of ca. 30 µm, and a cloud comprising several millions of points are obtained.

Request for a quote

QUELLTECH GMBH

Germany

QuellTech Solution: The performance of a manual inspection cannot be compared with the speed and the repeatability of a contactless QuellTech Q4-1000 laser scanner. It is even possible to install several instruments in parallel to cover the whole width of the ingot with one single scan. These instruments are mounted on an existing portal and correctly synchronized, so that interaction of the laser light originating from the other scanners is excluded. The QuellTech laser line scanners produce 3D point cloud of the raw ingot surface, and the software calculates the coordinates of the highest and deepest levels of this surface. After scalping the flat surface can be scanned again for any defects. Benefits for the Client: Thanks to QuellTech’s wide area laser line scanners, the cycle times for ingot scalping could considerably be reduced, and excessive material scrap due to a too low scalping level is prevented.

Request for a quote

QUELLTECH GMBH

Germany

Rotationally symmetrical driving gears in a line producing for automotive industry are mutually connected by electron beam welding. The camera inspection carried out until was not able to assess the quality of the weld seams at the required precision. Non-contact laser measurement system Particular Challenge: As the welding seams show a high reflectivity and are located at a position hard to access, inspection is difficult, all the more so as they dispose of a width of only 500µm. Therefore it is quite a challenge for the laser measurement system. The QuellTech solution: A QuellTech Laser Scanner Q4-5 with extremely small shape factor and high resolution proved to be perfectly suited for this application. In order to suppress reflections from elements in the surroundings, a particular algorithm has been integrated. Furthermore, this laser measurement system features a particularly adapted laser wavelength and an ultrafine laser line.

Request for a quote

QUELLTECH GMBH

Germany

Testing requirements for a manufacturer in electronics industries had changed: For an assembly included in a smartphone, the absence of contact between speaker ultra fine wires and adjacent components is essential. Fulfillment of this condition, until now only subjected random sampling by microscopy, from now on has to be verified in a 100% procedure. Due to labor cost, microscopy for this amount of inspection is no more lucrative. Detection of ultra fine wires in electronic device The particular challenge The fine wires made of copper in smartphone speakers dispose of a high reflection and only a small diameter. The QuellTech Solution A high-resolution QuellTech 2D/3D Q4-5 Laser, featuring a particularly adapted laser wavelength and an ultrafine laser line in the corresponding installation, is combined with a linear axis equipped with a convenient encoder output. Due to its special chip analysis, the Quelltech sensor delivers a stable and highly reproducible signal on the fine wires

Request for a quote

QUELLTECH GMBH

Germany

Plastic Mold Part (AC Controller) Inspection At this point the manufacturer is looking for scratches and chips and dimension specifications manually. In this respect manual inspection is not a repeatable or trustworthy method to guarantee steady quality of goods. It will be demanding for a human worker to detect this for a long period. QuellTech Solution Plastic Mold Parts are easily measurable materials for QuellTech scanners. Using the QuellTech Q4-120 Laser Line Scanner it is possible to obtain very precise reflection free 3D point clouds. A Software making necessary detections in 3D point clouds can effortlessly check dimensions and find scratches or any other defect which allows the manufacturer to automatically parse outparts that do not pass the tolerance levels.

Request for a quote

MICRO-EPSILON

Germany

The optoNCDT LL laser sensors produce an oval-shaped light spot of just a few millimeters in width which reminds of a short "laser line" (LL). This oval light spot compensates for inhomogeneous surface structures and the so-called "speckling" effect which particularly occurs with metallic surfaces. Combined with special software algorithms, interferences caused by surface roughness, defects, indentations or holes are filtered out. This enables stable and precise measurement results.

Request for a quote

MICRO-EPSILON

Germany

thicknessGAUGE C.LP sensor systems use laser profile scanners for the thickness measurement. These scanners project a laser line onto the surface to be measured. The laser line compensates for strip tilting and enables profile averaging. The laser line measuring technique makes it possible to measure the thickness of structured materials such as embossed surfaces and perforated plates.

Request for a quote

SITEC INDUSTRIETECHNOLOGIE GMBH

Germany

Together with our customers, we develop scalable control and automation solutions for their assembly, laser and ECM lines to meet their requirements. In doing so, we attach great importance to the topicality and future-proof development of the technology used. Programming under SIEMENS SPS, SIEMENS NC, BECKHOFF HMI and robot technology are our specialties. We are experts in realization drive and feedback control engineering, electrical project planning, control-cabinet construction, software development and control engineering.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

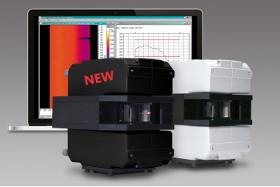

The MP Linescanner Series from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and product. Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized applications and industrial environments. With scan speeds up to 300Hz and the ability to scan up to 1024 data points in a single scan, the MP Linescanner Series can provide a complete picture of even the highest speed manufacturing processes. Additionally, with a 90° field-of-view and up to 200:1 optics, each spot on the target surface is capable of being sampled up to three times, ensuring an accurate temperature reading. Each linescanner also includes a built-in line laser for rapid

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The HBP1100 - HBP1500 / HBP1100A - HBP1500A are series of semi-automatic and automatic large bandsaws manufactured by Behringer. The large-scale universal machines from BEHRINGER can handle any job that is needed. Their expertise: Handling heavy-duty workpieces with ease and slicing through the material with extreme cutting performance. When processing long solid workpieces – rolled or rough turned – or processing large pipes, these benefits make for dramatic improvements in productivity. Round or rectangular – the results are equally impressive. In the BEHRINGER semi-automatic models, the material is positioned by eye, for instance with the aid of a line laser. For longer cut piece lengths, we recommend using a measuring device for precise positioning. The use of a feed gripper allows automatic sawing of solid material or pipes.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

• Real-time thermal imaging, scan speed up to 300 Hz • Up to 1024 measurement points per line • Wide choice of spectral and temperature ranges • High-quality brushless motor (MTBF 40,000 h) • Built-in Ethernet TCP/IP communications • PC independent alarm output • PC independent 4-20 mA interfaces (3 outputs) • I/O module support for up to 10 sectors/zones (PC independent) • Internal Line Laser for accurate alignment • Rugged, waterproof IP65 enclosure • Air purge keeps window free of dirt and condensation • Built-in water cooling for ambient up to 180 °C (356 °F)

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Raytek MP150 infrared linescanner is designed for temperature monitoring in demanding industrial environments. It generates accurate thermal images of moving objects, scanning up to 90° wide fields of view with a motorized mirror at up to 1024 points per line and at a max. 150 Hz frequency. An internal high-speed microprocessor calculates the temperature of the individual measurement points. — Real-time thermal line-scanner system for continuous or discrete process measurements — Optical resolution up to 200:1 — Built-in line laser for rapid alignment — On-board Ethernet TCP/IP communication — Wide choice of models and spectral responses The Raytek MP150 includes provision for air or water-cooling, three configurable analog outputs, and two-way digital communications. It can be used in standalone mode, connected to a single PC or integrated into a process control system using the Windows-based DataTemp DP software for remote configuration and real-time process monitoring.

Request for a quote

ERGOPACK DEUTSCHLAND GMBH

Germany

713X \ 726X \ 745X – WITH ELECTRONICALLY CONTROLLED DRIVE & CONTROL VIA JOYSTICK – LITHIUM BATTERY – CHARGER – LINE LASER – ERGOPACK TOOL-LIFT – SEALING TOOL – CONTROL VIA INDUSTRY TOUCHSCREEN INTERESTED? WE WOULD BE HAPPY TO VISIT YOU AND CONFIGURE THE SYSTEM INDIVIDUALLY WITH YOU ON SITE. 700X WITH ELECTRONICALLY CONTROLLED DRIVE & CONTROL VIA JOYSTICK LITHIUM BATTERY CHARGER CONTROL VIA INDUSTRY TOUCHSCREEN

Request for a quote

TOPTICA PHOTONICS AG

Germany

The FPI 100 is a confocal, scanning Fabry-Perot interferometer with a built-in photodetector unit, designed for measuring and controlling the mode profiles of continuous wave (cw) lasers. The FPI is available with different mirror sets and photodetectors for wavelength ranges between 330 nm and 3000 nm. The standard mirror reflectivity is 99.8 %, corresponding to a typical finesse of > 400, resolving even narrow laser lines.

Request for a quote

TOPTICA PHOTONICS AG

Germany

TOPTICA's iChrome CLE is a compact laser engine that combines four laser lines in one box. All integrated colors are provided via one polarization-maintaining single-mode fiber. It is available with 405, 488, 561 and 640 nm and more than 20 mW guaranteed output power after the fiber each. The system guarantees a plug & play installation since it includes TOPTICA's proprietary COOLAC automatic alignment technology.

Request for a quote

3D-MICROMAC AG

Germany

Applications: - Excimer Laser-Lift-Off using line-beam systems - Laser drilling and ablation using scanner systems or mask projection - Laser engraving of optical materials - Materials: polymers, polymer compounds, glass materials

Request for a quote

SHINING 3D TECHNOLOGY GMBH

Germany

FreeScan UE Pro Laser Handheld 3D Scanner inherits the highprecision, metrologygrade accuracy, and lightweight design of FreeScan UE, while improving the ability of fine scanning and global precision control of largescale workpiece scanning. It adopts 26+5+1 blue laser lines and integrates a photogrammetric module. Taking into account speed, accuracy and details, this professional 3D metrology solution can be applied to different sized scanning scenarios and perform metrologygrade accuracy inspection, reverse design, additive manufacturing and other applications.MetrologyGrade High Accuracy Accuracy up to 0.02mm, delivers consistent scanning results with high precision.Integrated photogrammetry function no need to apply coded targets, quickly locks the spatial position of the target frame.13 cross laser lines to scan large objects quickly, 5 parallel laser lines to scan fine details and single laser line for deep hole and pocket area scanning.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

3D-MICROMAC AG

Germany

3DMicromac’s microMIRA™ LLO system provides highly uniform, force free lift off of different layers on wafers at high processing speed. The unique line beam system is built on a highly customizable platform that can incorporate different laser sources, wavelengths and beam paths to meet each customer’s unique requirements. The laser system can be used for a variety of applications, such as GaN lift off from glass and sapphire substrates in microLED display manufacturing as well as in semiconductor manufacturing. Additional applications include laser annealing and crystallization for surface modification. Force free and extremely fast line beam laser processing No damage due to thermo-mechanical effects Low production costs Elimination of costly and polluting wet chemical processes Integration of adjacent manufacturing steps for higher fab productivity

Request for a quote

COGNEX CORPORATION

Germany

DSMax is the fastest and highest definition laser line 3D displacement sensor on the market for acquiring images and inspecting products in 3D. It is the only sensor that offers: — High scan rates (up to 18 kHz) at full measurement range — Maximum resolution images (2,000 profile points) — Fast high dynamic range (HDR) image These features make it the ideal solution for measuring and inspecting very small parts, such as electronic components, which can contain highly reflective or dark features.

Request for a quote

ROTHBUCHER SYSTEME

Germany

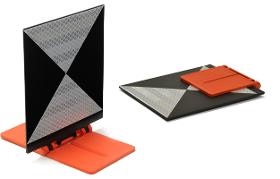

Target with foldable base RSLT10 The laser target RSLT10 has been developed for quickly setting up a line laser into an accurate position along the axis. Position the laser target at your reference point opposite your laser. Afterwards direct the laser with the activated axis line to the centre of the laser target by moving the laser to the left and to the right so you can see the line on the target. Important: The target makes the laser line visible only if you stand in line with your head at the same height as the laser. The laser target can be used up to a distance of 30 meters even on sunny days. The laser target is foldable and can easily transported directly in the laser case.

Request for a quoteResults for

Laser lines - Import exportNumber of results

21 ProductsCountries

Company type

Category

- Sensors (4)

- Laser - cutting and welding machines (2)

- Measurement - Equipment & Instruments (1)

- Construction - Machines & Equipment (1)

- 3D scanner (1)

- Infrared tubes (1)

- Light-emitting diode LED (1)

- Machine vision system (1)

- Measurement and regulation equipment and instruments - temperature (1)

- Measurement equipment and instruments - position and distance (1)

- Palletising machinery (1)

- Sawing machine tools (1)