- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- large parts

Results for

Large parts - Import export

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

Sensors of the IFE family with a length of up to 900 mm are used to detect large metallic objects and offer a switching distance of up to 180 mm. The sensors are very robust, water-tight according to IP 68 and thus also suitable for outdoor use. The proximity switches are based on the proven inductive principle and switch con tactless when a metallic object moves close. Sensors of the family replace several inductive sensors connected in series. With their large sensor surface the reliably detect large moving metal parts. The sensors check for example the reinforcement in cast concrete parts during quality control or report the presence of railway rails for onward transport.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Storage systems from Lödige provide a total integrated solution for parts and tools to be stored in an efficient and save-spacing saving way. Lödige storage systems can be fully automated to store and transport anything from small parts to very large and heavy aircraft parts and tools. We develop high-throughput storage systems in line with customer requirements to support your dispatch reliability and speed.

Request for a quote

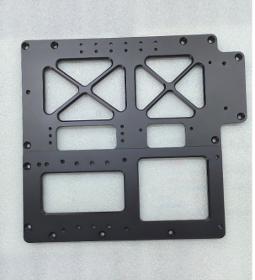

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

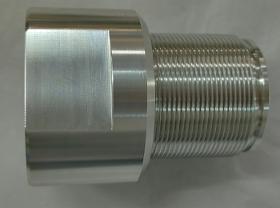

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Large mechanical aluminum screw fittings.

Request for a quote

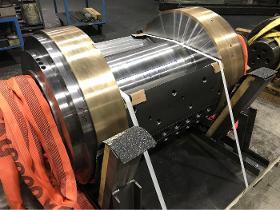

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accssoris used in large machinery parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Large machinery parts,Textile machine accessories.China cnc machining workpiece

Request for a quote

SPRIMAG SPRITZMASCHINENBAU GMBH & CO. KG

Germany

coating machine for large parts

Request for a quote

ING. KURT SCHADE GMBH & CO. KG

Germany

Our many years of experience in the fields of steel construction and CNC machining also make us a competent service provider in the field of repairs. Contact us – together we will find the optimal solution!

Request for a quote

ING. KURT SCHADE GMBH & CO. KG

Germany

With the complete assembly of assemblies, we offer you an all-round package: - We buy all the materials you need. - We straighten, staple and MIG MAG weld the individual steel construction components exactly according to your specifications and complete the components using high-precision CNC machining. - We assemble the finished, repeatedly tested components in our 2000 square meter assembly hall according to your construction plans into ready-to-install modules. - We check the final assembly down to the smallest detail. - We deliver the finished end product to you. Are you looking for a reliable service provider to implement your next project? We look forward to your inquiry.

Request for a quote

CINCHSEAL EUROPE GMBH

Germany

Production of elastic and plastic components for all industrial sectors up to racing technology. No matter if single piece - sample production - small series - large series or the production of prototypes. Almost EVERYTHING is possible - and this means from the smallest miniature component (Ø 1 mm) up to large parts (currently Ø 2500 mm).

Request for a quote

SPANSET SECUTEX GMBH

Germany

Machine elements and casted parts must be turned frequently during the manufacturing process and for shipping. The components are getting bigger and bigger and the demands on quality and time are getting higher and higher. Expensive cranes are often blocked for hours for the challenging turning operations and a large part of the production areas cannot be used during this time. SpanSetsecutex coatings for lifting slings and protective sleeves are used daily for lifting and moving sharpedged loads. For the safe and economical turning of heavy and difficult loads, secutex has now developed the turning slings with the new secuWave coating (patent pending). The unique feature of the secutex turning slings is the new wave profile. It combines the wellknown advantages of secutex coatings – excellent cut resistance and flexibility as well as a very high wear and abrasion resistance

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Milling of complex components for automotive and mechanical engineering. Production of prototypes, test parts, small and large series according to data records, drawings, samples or specifications. Machining of cast and forged blanks. Attachment of decorative surfaces.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 0.02 class calibration resistors excel in their modern design and small mechanical dimensions. Their ruggedness also ensures a long life. Calibration resistors of the 1240 series are used wherever very constant operating standards are required. Typical main areas of application therefore include: — When normal resistors prove to be too large scale — For test and calibration of resistance measurement devices — For tests on electrical temperature measuring equipment — For laboratory setup of a Wheatstone bridge — As shunt resistor for accurate current measurement — As part of standard equipment in research laboratories — For a large part of measurements in calibration laboratory. Features: — Range 10 μΩ ... 100 kΩ — Low capacitance and low inductance design — Suitable for direct current and technical frequencies — High stability < ± 0.01 % over years

Request for a quote

TFP TECHNOLOGY GMBH

Germany

With our CNC-fiber laying technlogy we can manufacture carbon preforms up to 2500x2000mm. That way producing composite parts in large dimensions will not be a problem. The usage of different fibers (carbon, glass and aramid) is possible too. Please contact us.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We offer customized die-cast parts, stamped parts, deep-drawn parts, turned parts, milled parts and contact springs, both as small-precision and large parts. Partial or complete plastic and rubber injection molding of metal parts is also part of our portfolio. The manufactured metal parts can be completed with sealing elements, threaded inserts and bearing bushes. We also offer processes for cold pressing, as well as cost-effective surface finishing. We accompany our customers throughout the entire project process and organize the tool and sample production as well as the production (including surface finishing) and optionally also the assembly of the series parts.

Request for a quote

HE-JA VERPACKUNGSMASCHINEN GMBH

Germany

Spare parts supply, retrofits, upgrades, consulting and service for HE-JA and Höller/Weldotron machines, all from one source. We have a large stock of critical spare parts in order to be able to help quickly in an emergency. Talk to us, we will help you!

Request for a quote

CIC - KLAUS CZERWONKA

Germany

CNC sheet metal processing, CNC laser parts, stamped parts, fine stamped parts, bent parts, pipe processing, cold forming, heat shielding sheets, deep-drawn parts, sheet metal parts from progressive dies, sheet metal parts assembled, sheet metal parts with surface treatment, sheet metal parts in large series, one-off production, prototypes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

We process the following materials: ■ chrome-nickel steel ■ various types of steel ■ non-ferrous metals ■ various aluminium alloys steel processing, stainless steel, machine engineering, tool engineering, metal processing, sheet steel processing, material 16 Mo3, Hardox, 1.4301, 1.4571, 1.4404, S355, S235, metal products, steel products, supplier construction machinery, power station, energy station, offshore equipment, pipes, steel halls, metal construction, profiles, handrails, balconies, stairs, roofing, pallet warehouse, pallet inverters, scrap conveyors, transport racks, special frames, devices, die blocks, barrel press, fork shoes, fork extensions, industrial gates, fences, customized constructions, industrial service, furnaces, playgrounds, sports fields, cladding, casing, housing, covers, noise-protection cabins, machine frames, large milled parts, conveyor technology, conveyor line, plunge pools, tank barrels and much more

Request for a quote

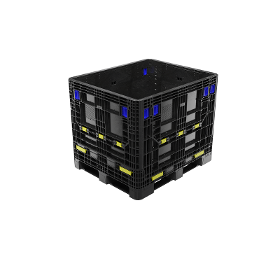

ORBIS EUROPE

Germany

ORBIS reusable bulk containers are designed to protect and transport heavy parts in automotive and industrial applications. Engineered for rugged applications, the plastic bulk containers are extremely robust and offer comprehensive product protection over a long service life. The 1200 x 1000 plastic bulk containers are available in multiple heights for increased packing density. The collapsible design with a return ratio of up to 1 : 3 reduces the shipping of air during return transport to a minimum. Key features: - manufactured from recycled material - multiple heights, access door and bottom configurations - durable all-plastic design - improved workplace safety - easy, on-site repair and part replacement - 100% recyclable

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently grip components of different dimensions, geometries and surface structures opens up completely new possibilities for you. Benefit from ✅ Increased efficiency of your processes ✅ Higher availability of your personnel ✅ Increased production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Personnel deployment ❌ Process complexity Possible applications of the FH-R15 ✅ Industrial robot applications for components up to 8 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Transporting parts (e.g. large sheet metal parts such as fenders or hoods) ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Use with collaborative robots

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently grip components of different dimensions, geometries and surface structures opens up completely new possibilities. Benefit from ✅ Increased efficiency of your processes ✅ Higher availability of your personnel ✅ Increased production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Employment of personnel ❌ Process complexity Possible applications of the FH-E3020 ✅ Industrial robot applications for components up to 25 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Transporting parts (e.g. large, flat sheet metal parts such as fenders or hoods) ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Tube lifter applications

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Change over from O.D. clamping to jaw clamping or centric clamping in 2 minutes – without clamping device change-over and without having to align ? No problem, with the jaw modules. Because the basic unit, into which the jaw module is inserted, is a HAINBUCH chuck or stationary chuck. If at times the clamping head reaches its limits because it must clamp a larger area, then use one of the jaw modules. The 3-jaw module is best suited for round workpieces, and if you have cubic workpieces, then rely on the 2-jaw module. This means that for a large parts spectrum you are completely flexible and always have the solution that is ideally suited for the respective clamping situation. Both are small, lightweight, and can be quickly changed over – an ingenious solution for small-series production.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Change over from O.D. clamping to jaw clamping or centric clamping in 2 minutes – without clamping device change-over and without having to align ? No problem, with the jaw modules. Because the basic unit, into which the jaw module is inserted, is a HAINBUCH chuck or stationary chuck. If at times the clamping head reaches its limits because it must clamp a larger area, then use one of the jaw modules. The 3-jaw module is best suited for round workpieces, and if you have cubic workpieces, then rely on the 2-jaw module. This means that for a large parts spectrum you are completely flexible and always have the solution that is ideally suited for the respective clamping situation. Both are small, lightweight, and can be quickly changed over – an ingenious solution for small-series production.

Request for a quote

ROLEC GEHÄUSE-SYSTEME GMBH

Germany

taraPLUS was developed for light to medium loads. It is quick and easy to assemble on site and the large openings in the system parts allow cables to be easily fed through. The special design combines round and square profiles, thereby achieving high static equilibrium. taraPLUS is a tried and trusted system with ingress protection of IP 54.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

HAND-Demagnetizers be used for degaussing of large parts or workpieces, which cannot be done to the device for other reasons, for example, Injection molds, stamping tools, vices built, clamped tools, etc. This portable model can be used for a maximum of 10 minutes of continuous operation. It is equipped with a thermostat that switches it off when the maximum permitted temperature (60ºC) is reached; it can only be used again once the temperature has dropped. The device is moved by hand over the workpiece, as close as possible to the surface, but without touching it.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Chamber dryers are ideal for small lot sizes and intermittent drying. Chamber dryers are suitable for the batch drying of the most diverse goods and for large-format parts with long drying times. The drying process can be individually adapted to the parts by means of the drying duration or temperature. The dryers are fed either manually or fully automatically.

Request for a quote

COMET YXLON GMBH

Germany

The YXLON UX20 system for X-ray and CT inspection of medium to large cast parts makes inspections easier than ever. The award winning user interface Geminy enables an easy inspection, both for your 2D and 3D inspection needs. Our efficient workflows with automation, wizards and presets guide the user. From novice to expert, all levels will discover intuitive controls. The operator makes consistent inspection decisions with our optimized image chain. It combines x-ray tube, detector and image processing providing benchmark image quality. Easy inspection is the sum of many parts. The operator desk, for example, has the absolute essentials you need. You can also vary the height of the desk to accommodate operation from a sitting or standing position. A number of options and upgrades offer possibilities to let the system grow with the demands of the operator. This ensures that the investment is future-proof and benefits from technical advancements for a lifetime.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Water-sprinkled spray walls and spray booths with automatic paint sludge filtration system In wet separation, the overspray meets the water film of the spray wall and is thereby bound in the water. The sludge formed by this is discharged using sludge filtration systems. Water-sprinkled spray walls The overspray is sucked in in the lower area of the vertical water drain surface and is bound in water when it meets the film of water. The paint mist is washed out further in the lower section of the washout tower using a vortex washing system with downstream baffle plate separator. In order to replace the water lost due to evaporation, it is recommended to fit an automatic water level controller. The entire quantity of water is fed to the automatic paint sludge filtration system via the disposal pump. A coagulant is added to the water by an automatic dosing unit, as a result of which the paint sludge in the circulating water is disbonded and can be separated more easily. The cleaning of the circulating water takes place in the separately arranged paint sludge filtration system. Depending on the paint system and plant version, the separation system is operated using a full or partial current method. Water-sprinkled spray walls/booths with underfloor paint mist extraction For the painting of large parts with a high paint throughput. The paint mist is sucked in under the grating cover. A substantial part of the overspray is already bound in the water by the constant sprinkling of the entire floor of the basin. The paint mist is washed out further in the lower section of the washout tower using a vortex washing system with downstream baffle plate separator. Optimum capture of the paint mist is guaranteed by the laminar air flow inside the booth. A further advantage over comparable systems is the low water basin height and the associated low foundation depth. The sludge formed by this is discharged using sludge filtration systems. Advantages

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Standard advantages: RTS-Rotation – low-maintenance dry spray booth Overspray dry separation demonstrates its strengths in practice above all when relatively large quantities of paint have to be processed and the overspray portion cannot be reduced any further. Spray booth with dry separation are usually equipped with disposable filters or manually regenerative filters. These cause costs for spare filters, maintenance and disposal. In addition to that, operation has to be interrupted in order to exchange the filters. The ‘RTS rotation’ system was developed by Rippert in order to reduce these costs and tooling times. Maintenance intervals and filter service lives are prolonged significantly in comparison with conventional systems due to the new brush pre-filtration. How the ‘RTS-Rotation’ system works Overspray separation in the RTS-Rotation system takes place by means of a pre-filter and a fine filter stage. The pre-filter stage is formed by vertical, slowly rotating brush rollers. The bristles present a very large total surface area and absorb the adhesive particles from the overspray. During the slow rotation, the paint particles can dry on the tips of the bristles. This results in slowly growing cakings on the bristles. Scrapers are mounted in the area behind the brush rollers that continuously remove these cakings from the bristles. The dislodged, hardened material falls into the drawers arranged under the brushes and can thus be simply disposed of. The dry paint dust may often be disposed of as ‘commercial waste’. The brushes otherwise require little maintenance and do not need to be exchanged or renewed. The fine filter stage is formed by a special fleece filter, which is arranged above the brush rollers and must be manually maintained or exchanged in the standard version. The maintenance intervals depend on the paint material used. Automatic cleaning or an external fine filter with automatic cleaning is also possible as an option. Over 10 years of operational experience shows that around 75 to 95% of the overspray is separated out by the pre-filter stage and the rest by the fine filter stage. The degree of separation depends strongly on the type of paint and the drying reactivity during the flying phase. Use of the RTS-Rotation with the following paints Before practical use, the paints are tested and approved in Rippert’s own pilot plant. Stove enamels and 100% UV paint systems cannot be used. The horizontal version Furthermore, it is possible to use the system as a horizontal underfloor extraction system. This version is used, for example, by a machine manufacturer for large parts. In addition, a drag conveyor with gulley extraction is used there in order to automatically transport the particles cleaned off the brushes out of the pit. Conclusion The RTS-Rotation system is particularly useful when relatively large quantities of paint with an unavoidable overspray portion have to be processed, as otherwise a great deal of residual waste would result using conventional technology. Compared to water-sprinkled spray walls and normal dry spray booths the amortisation period is shorter; it is frequently less than two years.

Request for a quoteResults for

Large parts - Import exportNumber of results

83 ProductsCountries

- Germany (83)

- Bonn, Düsseldorf and North Rhine and Westphalia (32)

- Bremen and region (1)

- Frankfurt am Main and Hesse (4)

- Hamburg and region (1)

- Hannover and Lower Saxony (6)

- Kiel and Schleswig-Holstein (1)

- Leipzig and Saxony (1)

- Munich, Nuremberg and Bavaria (7)

- Potsdam and Brandenburg (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (25)

- Weimar and Thuringia (4)

Company type

Category

- Vacuum cleaners, domestic (6)

- Printers - computer (4)

- Sandblasting equipment (3)

- Cleaning machines, industrial (3)

- Machine tools - metal machining (3)

- Machine tools, metal machining - parts and accessories (3)

- Laser - cutting and welding machines (2)

- Metallurgy - machinery and installations (2)

- Milling - machine tools (2)

- Automation - systems and equipment (2)

- Electrical components and parts (2)

- Mechanical engineering - custom work (2)

- Metal industrial presses (2)

- Vehicles - mechanical components and parts (2)

- Components and parts for large household appliances (1)

- Adjustment - machine tools (1)

- Aeronautical equipment manufacturers (1)

- Boxes, plastic (1)

- Carbon by-products (1)

- Clothing accessories (1)