- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- labelling systems

Results for

Labelling systems - Import export

BIZERBA SE & CO. KG

Germany

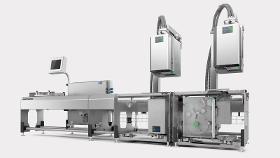

High-tech meeting the highest demands. More customer benefits for future requirements Intelligent Weigh Price goods labelling system from Bizerba. Unique in it's class and recognised as the worlds leading experts in weigh price labelling systems for the food industry. High Speed High IP protection with intuitive BRAIN software. Easy to operate and maintain incorporating the Bizerba quick belt change system that does not require tools. The flexible system will easily incorporate into existing production lines seamlessly. Additionally the system will talk to existing software packages with our _Connect BRAIN software module. The Intelligent Weigh Price goods labelling system weighs, labels rejects inferior weights automatically. Depending on the speed requirements and the lines the Weigh Price Goods Labelling System can achieve up wards of 170 packages per minute. High-tech meeting the highest demands. More customer benefits for future requirements. The intelligent labelling...

Request for a quote

BIZERBA SE & CO. KG

Germany

Big 3: Performance, Plug-In ® label and Quality Check Inside - more customer benefits for future requirements The weigh price labeller GLM-Ievo intelligently designed for automatic weighing and labelling of pre-packaged goods comes in different versions. The Weigh Price Goods Labelling System GLM-Ievo 170 will achieve over 170 packs per minute. Due to its modular design, it can be optimally configured for alternative products and offers exemplary performance requirements in the food production area. Thanks to the modular system of the weigh price labeller, there are no limits for todays and any future requirements you may have in the industrial food area. Besides its flexibility, this labelling system stands out in terms of robustness and an easy-to-clean design. With intelligent visual quality control and automated activation of process data via the new function Plug-In® Label operation it is easy to maintain and manage thereby reducing errors during the packaging...

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

Due to the ever-increasing number of parcels that are shipped every day, the need for automated solutions for the shipping process is also growing. Fully automated labeling of shipping cartons is becoming increasingly relevant for logistics and e-commerce companies. With our fully automatic labeling system, you can print and apply your goods in just one step. Convince yourself of our MPERIA A-Series labeler in combination with the QuickTamp applicator. The advantages at a glance: - Labeling from above or from the side - Cartons of different heights thanks to integrated height gauge - Height differences of up to 1 m between consecutive packages - Conveying speeds of up to 80 m/min - Applicator arm made of carbon fiber - Stroke length of up to 1,170 mm - Simple and tool-free maintenance - Labels up to 176×240 mm format - No bulky protective housing required - Intuitive control software with touch display and remote function - Less than 1 m² footprint

Request for a quote

ETIKETTENDRUCK FÖRSTER GMBH & CO.KG

Germany

We have been designing and producing UL labels for well-known industrial companies since 1990. The requirements and regulations are very complex and may require a detailed consultation in order to explain the UL-compliant marking and the different application programs. The UL certification of an end product by an OEM (Original Equipment Manufacturer) refers to every single component of the product. A label is such a component whose requirements are regulated in the UL 969 “Standard for Marking & Labeling Systems”.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Labelling machine for wrap-around labelling Basic concept of the system for bottle labelling and can labelling: With the aid of the fully automatic VRM labeller, different cylindrical or square products can be labelled quickly and precisely on the circumference - wrap-around labelling. The machine is therefore used in many industries, from pharmaceuticals to food and cosmetics. The VRM series is suitable for bottle labelling, can labelling, vial labelling or for comparable containers such as jars or bottles. Several different formats can be covered simultaneously with one model. The VRM-DS labelling system includes a 3-roll turning station and is used for outputs of up to 60 products per minute. It is characterised by the highest labelling accuracy and can optionally align the containers on the basis of a weld seam, print mark or other feature before labelling (target labelling).

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The system is used for labelling or printing flat products such as postcards, flat folding boxes, mailing bags or textile blanks, regardless of the format. The products are fed into the loading chute by the operator and are then destacked layer by layer from below and fed past the labeling or printing or inspection unit. The finished products are then collected in an exit chute or a collection box. This system was developed for a capacity range of up to 100 products/min. For processing higher numbers of products/min, the HSF model series is available which, in addition to a longer conveying distance for setting up different stations also provides the option of a product ejector to automatically remove NIO products from the process and collect them in a separate collection box. The tool-free adjustment enables the shortest changeover times for batch/product changes.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The RML labeling machine is suitable for wrap-around labeling of non-rigid cylindrical products - ampoule, cartridge, syringe labeling. The products are transported to the labeling station, which fixes the label on the circumference, by means of an intermittent roller conveyor. The labeling system is suitable for products such as ampoules, cartridges, lipsticks, syringes and vials and is therefore suitable for the pharmaceutical, medical technology, cosmetics and food industries, where reliable labeling and control processes are extremely important. Deviations and errors here can lead to life-threatening situations. From manual loading and unloading to fully automatic loading and subsequent collection of the products, this model is modularly expandable. Particularly narrow products such as ampoules or cartridges can also be processed using format sets (RML-FS).

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The PAE range is an innovative new generation of pallet labellers that can label pallets on up to three sides with either pneumatic and/or electric traversing axles. The labels are printed with individual data in real time immediately before dispensing. The series is designed to integrate thermal transfer printing modules from different manufacturers. Automatic height adjustments are available as an option in order to Application heights on the pallet to start up. The complete traceability of products is essential nowadays, which is why interest in intelligent pallet labelling processes is so high. The system can handle label formats up to DIN A4 format, enabling product labelling according to the global GS1 standards.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Due to increasing product counterfeiting, many manufacturers are forced to make their products tamper- and counterfeit-proof. Legal requirements exist in some countries for this purpose. Our TE model was developed for this task. The system enables single-sided and/or double-sided seal labeling of pharmaceutical folding boxes and can also be used in the cosmetics industry. During the development, special attention was paid to the protection of the packaging as well as the format range of the products to be processed. The basic version labels folding boxes with format widths (in the running direction) of 50-250 mm at an output of up to 300 folding boxes per minute. Models for processing wider folding cartons are based on the same line concept. As an extension, the model series is available as a combination system (TE-PV) with a b+b serialization module and b+b LineManager. In this case, the printer and camera system are integrated into the system.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Due to lower storage costs and higher flexibility, more and more manufacturers rely on the processing of unprinted tubes and mark them with a label directly before filling. The labeler TEM model was developed for this purpose and is able to apply a label to the circumference of the empty, unsealed tubes. For this purpose, the products are transported via a clocked transport system to the labeling station, where they are previously aligned and stabilized by means of a format-specific mandrel. The model can optionally be extended to include infeed and outfeed magazines and/or steep conveyors into the tube filler. As a double-cycle variant, throughput can be doubled. Special sensor technology makes target labeling possible based on print marks or lid features. Models: TEM \ Empty, unsealed tubes \ 50 - 60 products/min TEM-2T \ Empty, unsealed tubes \ 100 - 120 products/min

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The workstation enables the manual serialisation of pharmaceutical packs and their aggregation into shipping cartons. For this purpose, each individual box is first printed with order-related serialisation data by a thermal inkjet printing system and then manually placed in a shipping carton. As soon as this is filled, the downstream thermal transfer printer creates an individual serialisation label. The correct print data and print quality are monitored by a camera system. The operator places the drug packs to be labelled at a reference edge of the conveyor belt. As soon as the printer has printed the serialisation data, it is checked for correctness by the integrated image processing system. In case of an error, the product stops at a certain position, which is marked by red LEDs. Depending on the number of products in the shipping carton/number of aggregation levels, approx. 10-12 products/min are serialised.

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

High-performing, robust labelers for applying decorative, informative and branding labels in demanding environments in continuous operation, 24 hours per day, 7 days a week. Integrated design with a small footprint makes this ALS range easy to install in your new or existing production line, regardless of whether the label has to be applied on the top, on the side, around or on the bottom of your product. Intelligent features like dispensing edge, pneumatic applicators, Ethernet, IP65, tandem function and many more make the ALS range your preferred labeler.

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

Modular labeling system ALS 30x, especially developed for the most extreme labeling conditions and environments. Built to perform and support continuous labeling by using large label rolls, tandem application and fast service modules. Increase your productivity and production line performance by using our NOVEXX Solutions high-performance Labelers ALS 306 and ALS 309.

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

Whether it is canisters, large containers, drums or pallets, from barrels to aerosols – the new labeling system ALS 209 from NOVEXX Solutions will win you over with its labeling of a wide variety of products and packaging units. The ALS 209 applies labels with a very large width (up to 229 mm or 9 inches) and is extremely precise and reliable, even in harsh environments. Moreover, due to its extreme compactness, the ALS 209 can be used in a very flexible way. And thanks to its optional tandem function, down time when changing the material is a thing of the past. With the ALS 209, NOVEXX Solutions provides a very efficient and at the same time economically profitable labeling system. Whether it is canisters, large containers, drums or pallets, from barrels to aerosols – the new labeling system ALS 209 from NOVEXX Solutions will win you over with its labeling of a wide variety of products and packaging units.

Request for a quote

HERMA GMBH

Germany

High performance without compromise The wrap-around labeler is available in two versions: HERMA 132M - With the continuously rotating starwheel, up to 400 products/minute can be labeled. HERMA 040M - With the clocked starwheel, up to 120 products/minute can be labeled: Precision and reliable production make this easily convertible solution unbeatable - the clocked rotary star guarantees precise labeling with extreme performance. The compact, modular design from standard components enables the machines to be precisely and yet very economically assembled for individual requirements of individual users. Cylindrical products with one or two labels on the circumference can be labeled more cost-effectively and in less time. In addition to cost-effectiveness, the labeling system for wrap-around labeling offers a high standard of safety.

Request for a quote

HERMA GMBH

Germany

HERMA wrap-around labeler 152C: precise labeling at low cost Equipped with the high-performance labeler HERMA 500, it is suitable for up to 200 cylindrical products per minute The easy-to-maintain solution with a folding belt and back pressure plate offers amazing performance and a fast return on investment Most adjustments can be made without tools with little time required With the optional roller prism technology, even spiral misalignment is almost completely eliminated; even aligned labeling succeeds perfectly Clean Design with closed holes, minimum gaps and grooves, and rounded corners protects the 152C from contamination and makes it easy to clean and maintain Installation of a printer unit such as a hot stamp or thermal transfer printer is possible without any problems Is now available much faster due to the Clean Design and digitized ordering processes, optionally in EU or US versions.

Request for a quote

BIZERBA SE & CO. KG

Germany

Big 3: Performance, Plug-In ® label and Quality Check Inside - more customer benefits for future requirements The Weigh Price Goods Labelling System with the Big 3: Performance, Plug-In® label and Quality Check Inside - with more customer benefits for any future requirements. The intelligent labelling line GLM-Ievo Weigh Price goods labelling system designed for automatic weighing and labelling of pre-packaged goods comes in different versions depending on the products that need to be weighed and labelled. Due to its modular design, it can be optimally configured for products and performance requirements in the food production area. Additionally they will seamlessly integrate with inspection systems. Thanks to the modular system, there are no limits for today and any future requirements in the industrial food manufacturing area. In addition to its flexibility, this labelling system stands out in terms of technology, robustness and an easy-to-clean design. With intelligent...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BIZERBA SE & CO. KG

Germany

Optimizes package handling in material flow systems By channeling up to 6 product lanes into a single line the LCE allows controlled product feeding from the packaging machine to the price labeler. Due to specially formed and Teflon-coated alignment rails the converger belt proves its effectiveness especially for flat packages. It can be infinitely adjusted from 10 - 80 m/minute and individually set for each PLU.

Request for a quote

BIZERBA SE & CO. KG

Germany

For the formation of pre-defined package units downstream of a Bizerba labeling system The fully automatic TU 100 unit maker consists of an electrically driven, two-part package removal station with an electro-pneumatic diverter arm. It makes units according to predefined criteria, optimizing the packing process and the control of sum labels for the packages. Up to 100 packages per minute are possible. The TU 100 can be optionally fitted with a roller conveyor or a belt conveyor. (optional)

Request for a quote

BIZERBA SE & CO. KG

Germany

Thermal direct / thermal transfer printer for more features, more convenience, more functionality. Regardless if used as stand-alone printer, total printer or if used for weight-related product labeling, the GLP maxx with its Intel® Atom™-based hardware is the ideal solution for today's and tomorrow's requirements. The GLPmaxx can be used as a label printer for product labeling in the food processing industry as well as in manufacturing trade and logistics. It is perfectly suitable for dispatch and stock labels. In combination with the Bizerba weighing technology it is the perfect starter kit for manual price labeling.

Request for a quote

BIZERBA SE & CO. KG

Germany

Suitable as a stand alone printer, total printer or for weight-related product labeling The Label printer GLP-Imaxx in combination with the Bizerba weighing technology is the perfect starter kit for manual price labeling. GLP-Imaxx is suitable for label rolls with a diameter of up to 300 millimeters. Thus retrofitting time is reduced - especially with large labels. The printers are network compatible and can also be controlled directly via the Internet. Settings and maintenance of the printer unit can be made without need of any tools - reducing costs and increasing print quality.

Request for a quote

BIZERBA SE & CO. KG

Germany

Whether as a Windows® printer or part of a system network, the robust, stainless steel GLP-58 thermal printer impresses with its fast, reliable handling and multifunctionality. In combination with a range of Bizerba labeling systems, checkweighers and industrial terminals, it offers a wide variety of potential applications - both in manual labeling and statistical work. The label printer GLP 58-K on the ST terminal allows printing of up to three barcodes. It is possible to use not only standardized printing images but also custom layouts. The Windows® printer driver can be used to print out labels created using Windows® applications and the Bizerba Label Designer (BLD).

Request for a quote

BIZERBA SE & CO. KG

Germany

Industrial Barcode Label Printer with Thermal direct / thermal transfer printer for more features, more convenience, more functionality. Regardless if used as stand-alone printer, total printer or if used for weight-related product labeling, the GLP maxx with its Intel® Atom™-based hardware is the ideal solution for today's and tomorrow's requirements. The Industrial Barcode Label Printer with Thermal direct and thermal transfer printer packed with more features, more convenience, and more functionality. Regardless if used as stand-alone printer, total printer or if used for weight-related product for labelling, the GLP maxx with its Intel® Atom™-based hardware is the ideal solution for today and tomorrow's requirements. Future proof your business. The GLPmaxx Industrial Barcode Label Printer can be used as a label printer for product labelling in the food processing industry as well as in manufacturing trade and logistics. It is perfectly suitable for dispatch and stock labels....

Request for a quote

BIZERBA SE & CO. KG

Germany

Thermal direct / thermal transfer printer for more features, more convenience, more functionality. Regardless if used as stand-alone printer, total printer or if used for weight-related product labeling, the GLP maxx with its Intel® Atom™-based hardware is the ideal solution for today's and tomorrow's requirements. The GLPmaxx can be used as a label printer for product labeling in the food processing industry as well as in manufacturing trade and logistics. It is perfectly suitable for dispatch and stock labels. In combination with the Bizerba weighing technology it is the perfect starter kit for manual price labeling. The printers are network compatible and can also be controlled directly via the Internet. Settings and maintenance of the printer unit can be made without need of any tools - reducing costs and increasing print quality.

Request for a quote

METO INTERNATIONAL GMBH

Germany

Labeling and security in a single operation with electromagnetic and radio-frequency labels for Checkpoint merchandise security systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Labelling systems can be integrated, whether it is laser, needle or inkjet, to mark and identify the tubes. Other options that can be integrated are welding seam detection, length control or measurement of processed tubes. The corresponding sensor and camera technology can be implemented for the specific product. The following step can be carried out without any problems, whether it is cutting, punching, deburring of holes or seal testing with external systems. Smart data evaluation All the systems can be equipped with different control and IPC panels. Interfaces to data caption systems for consumption and operation make the digitalization and evaluation of the data. Marking system, Welding seam detection, Camera control system, Internal and external cleaning processes, Cleaning and suction, Hole punching, Deburring – chamfering

Request for a quote

BIZERBA SE & CO. KG

Germany

Checkweighing for dry areas and non-food applications Bizerba CWDmaxx series checkweighers are designed as entry-level checkweighing models for up to 250 weighings per minute. With an IP54 protection level the CWDmaxx is the first choice for all applications not requiring wet cleaning. It is built with a modular construction allowing for configurations of up to 5 belt modules to be made on one checkweigher, tailored to the specific application or areas that it is sited. Additionally the checkweighing systems are extremely flexible. Due to the modular design all the Bizerba checkweighing systems can easily be integrated with existing inspection systems to include x-ray food, food metal detectors and vision inspection systems. You may also be looking for weigh price labelling systems. Our GLM-Ievo range can boast a labelling speed of up to 170 packages per minute. The dynamic checkweighing system CWDmaxx is ideal for non food, we have an entire range of inspection systems for all...

Request for a quote

BIZERBA SE & CO. KG

Germany

For radiant surfaces Your high-quality machines deserve to be treated with care. Our stainless steel cleaner removes fingerprints and other traces from high-quality stainless steel and other metal surfaces without harming them. Area of Use Meat and bone saws Mincers Tenderizer / strip cutter Price labeling systems Logistics systems Checkweighers Compact and precision scales Load receptors Terminals Highlights Simple and gentle care for stainless steel and other metals High hygiene standard: NSF registration in category C1 Nonfood Compounds Anti-static effect prevents re-soiling

Request for a quote

BIZERBA SE & CO. KG

Germany

Efficient control of packaging and label content in labeling lines The Bizerba LabelSecure vision inspection system automatically checks label position and texts. Bizerba LabelSecure can be integrated in conveyor lines with dynamic checkweighers. Thereby offering a high level of flexibility and adaptability to existing systems. Used with an inline dynamic checkweigher the system will add another level of protection on your production line. Consider the Dynamic checkweigher CWEmaxx. The system will checkweigh and reject any over filled and under filled packages. In addition, the vision inspection system performance is impressive, automatic control of label position, texts and film colour. Any packages that do not conform to the programmed or set criteria will be rejected. Also, package sizes and bar codes are verifiable. All packages that fall outside of the date range set up in the Vision Inspection System will be rejected, Ensuring out of date or short sell by dated products...

Request for a quoteResults for

Labelling systems - Import exportNumber of results

98 ProductsCountries

Company type

Category

- Labelling machines (51)

- Food industry - machinery and equipment (13)

- Seals and packing material (6)

- Automation - systems and equipment (5)

- Fittings, pipe, tube and hose - plastic (5)

- Bar codes - printing machines (2)

- Chemicals and pharmaceuticals - packaging machinery (2)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Chemistry - laboratory products (1)

- Cleaning - steel and metals (1)

- Copper and copper alloys (1)

- Food Industry - Machines & Equipment (1)

- Measurement - Equipment & Instruments (1)

- Monitoring and control equipment (1)

- Pipes and tubes - ferrous metal (1)

- Potting equipment (1)

- Printers - computer (1)

- Sheet metals - stamping (1)

- Software (1)