- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- inkjet printing

Results for

Inkjet printing - Import export

MATTHEWS MARKING SYSTEMS

Germany

Matthews Marking Systems offers specialized inkjet and software solutions for the metal industry which can handle high temperatures, oily or dusty surfaces and changing material compositions. The MPERIA® V-Series enables clear marking on various materials and can be integrated into production systems. It is particularly suitable for machine builders and OEMs, with benefits such as specialty inks, low maintenance, high availability, robust design and flexible printhead mounting. Matthews' specialty inks are highly adhesive, fast drying and temperature resistant, ideal for aerospace and marine applications. The V-Series printheads are durable, low maintenance and enable automated cleaning processes. Large ink containers reduce maintenance cycles. The MPERIA® V-Series integrates into existing production lines and enables printing from different angles. Central control is provided by the MPERIA® universal controller, also in a version for harsh environments.

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

Industrial inkjet printers enable flexible, contactless and cost-effective marking of packaging, goods and pallets. They are suitable for various substrates and applications without disrupting the production process. Inkjet printers create the printed image by selectively releasing ink droplets and offer easy maintenance, a large distance between the print head and substrate, variable print content and flexible integration. Important selection criteria include production environment, size of print image, resolution, surface texture of the substrate, space and line speed. Matthews Marking Systems uses various inkjet printing processes and offers inks for porous and non-porous surfaces. The printers are suitable for many materials, including wood, plastic, metal, pallets, tires and corrugated cardboard. They can be adapted to individual space requirements and offer solutions for both dusty and clean production environments.

Request for a quote

MATTHEWS MARKING SYSTEMS

Germany

The piezo inkjet printer (PIJ) is an inkjet printer with a contactless printing process. This industrial marking and coding system is ideal for printing high-resolution text, graphics, barcodes and more on a variety of products and packaging materials. Compared to other brands, our piezo inkjet printer uses up to 35% less ink. The printheads are mainly used in industrial areas for marking secondary packaging (e.g. cartons, corrugated cardboard boxes and tray packs). However, our piezo inkjet printers also achieve excellent legibility on porous materials. By combining several print heads, it is possible to apply large-area markings and graphics. This ensures that your product information, logos and graphics are always presented in high quality and clear legibility. By replacing labeling systems or pre-printed cartons with a PIJ printer, you can reduce your production costs. Discover the outstanding print quality of our piezo inkjet printers and arrange a no-obligation test print.

Request for a quote

REA ELEKTRONIK GMBH

Germany

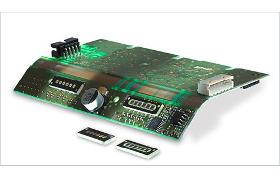

Coding, marking, pre-treatment in rough industrial environments. Print heads without compromises. The next generation is ready to take over. Speed potential pushed to another level, wear and tear significantly reduced. Print head brain work which pays off for our customers For improving our most legendary sturdy REA JET DOD large character print heads further on, we have been driven by two decisive customer needs: — Duplication of speed potential to up to 600 m/min — Multiplication of their durability by lowering wear and tear 7 nozzles = 5-27 mm 16 nozzles = 5-67 mm 32 nozzles = 5-140 mm

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

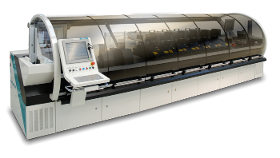

The LSS-PV model was developed to serialize small product batches cost-effectively and according to the requirements of country-specific FMD guidelines. The products are fed manually. A transport system with product carriers guarantees a precise and continuously accurate alignment of the products. After the printing process performed by a thermal inkjet printing system (TIJ), the print data is inspected. If the inspection result is positive, the products are either collected on the collection table at the outfeed of the system or glide over an optionally available transfer plate into an outer shipping case. Defective products are reliably separated from the GOOD products by the product reject station. This process is verified twice in the PLC.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This workstation enables the manual serialisation of drug packages and their aggregation into shipping cases. For this purpose, each individual box is first printed with order-related serialisation data by a thermal inkjet printing system as it passes by and then manually placed in a shipping carton. As soon as it is filled, the downstream thermal transfer label printer creates an individual serialisation label. The correct print data and print quality are permanently monitored by a vision system. The operator places the medicine products to be serialized on a reference edge at the infeed. As soon as the thermal inkjet printer has printed the serialisation data, the integrated vision system checks that the data is correct. If an error is detected (e.g. insufficient grading), the product stops at a certain position marked by red LEDs. The removal of the rejected product must be confirmed by pressing a button on the HMI.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The workstation enables the manual serialisation of pharmaceutical packs and their aggregation into shipping cartons. For this purpose, each individual box is first printed with order-related serialisation data by a thermal inkjet printing system and then manually placed in a shipping carton. As soon as this is filled, the downstream thermal transfer printer creates an individual serialisation label. The correct print data and print quality are monitored by a camera system. The operator places the drug packs to be labelled at a reference edge of the conveyor belt. As soon as the printer has printed the serialisation data, it is checked for correctness by the integrated image processing system. In case of an error, the product stops at a certain position, which is marked by red LEDs. Depending on the number of products in the shipping carton/number of aggregation levels, approx. 10-12 products/min are serialised.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This powerful HSF friction feeder is the optimal solution when empty folding boxes have to be marked with variable data offline from the production line. The modular design of the system enables an easy integration of the desired marking technology. The HSF separates the folding boxes from the stack in the infeed magazine. The cartons are guided to the printing station by two parallel running belt conveyors. Print information could be e.g. serialisation data in the form of bar codes or data matrix codes and text. Depending on requirements, thermal inkjet, laser coders or label print- and apply systems can be used (also in combination). The printed data is inspected and verified by an integrated vision system. The b+b Linemanager recognized all 21CFR Part 11 data for each serial number and is able to report this back to the Siteserver system (e.g. b+b Siteserver).

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

s with the MS-PV-AG model, the products are fed manually by the operator. Product carriers and adjustable guide rails ensure a stable product transport. As soon as the thermal inkjet printer has printed the serialisation data, the integrated vision system checks that the data is correct. If an error is detected (e.g. insufficient grading), the product is removed from the process and fed to a lockable collection box. It is not taken into account during the formation of the aggregation pedigree and is ejected and marked in the shift register as soon as the error is detected. As soon as the filling quantity per carton is reached according to the specified packing scheme, the system automatically generates a serialized label for the shipping carton. It is applied manually by the operator and confirmed by a handheld scanner that the aggregation label has been applied.

Request for a quote

RUHLAMAT GMBH

Germany

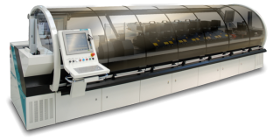

The LP2100 passport personalisation machine automatically handles passports and e-passports in ICAO ID-3 size. Colour printing, laser engraving, various monochrome printing systems, and contactless chip encoding stations can be installed on the machine according to the specific project requirements. Thus a customised configuration with a high level of flexibility and standardisation can be realised. A sophisticated multi-step transportation mode allows parallel processing to reach a high throughput. Several software solutions create a high level of security and make operation very easy. • High-quality personalisation (laser engraving or colour inkjet printing) • Printing of UV reflecting elements • Precise quality control (visual/electronic) • Highly modular design - easy to operate and maintain • Universal personalisation software - Data Mastery (DMS) as open platform • Production Data Management System (PDMS) optionally available • Solid machine design for precise quality...

Request for a quote

RUHLAMAT GMBH

Germany

Advanced customer expectations, strong market dynamics, new security threats, and cost pressure require new levels of efficiency and economy in card personalisation. The Pearl ID delivers the reliability, flexibility, security, and profitability to meet your specific needs in centralised card personalisation. With a throughput of up to 3,300 cards/hour, it is the ideal system for the high-speed production of ID cards, driver’s licences, health cards, payment cards, commercial cards, and other smart cards. You can choose from a comprehensive range of technologies, depending upon your personalisation requirements, production volumes, and growth objectives. The Pearl ID is supplied as tailor-made solution with automated inline quality control, and enables to combine laser engraving, industrial inkjet printing, security lamination, smart card encoding, and other technologies. Different laser systems for marking and optical personalisation can be integrated, with up to six laser heads...

Request for a quote

RUHLAMAT GMBH

Germany

The Pearl ID is a fast and modular personalisation system for all kind of personalisation tasks with unrivalled productivity. Superior quality, proven technologies and robust software allow you to meet even the most demanding production environments. Provides all the features and security you require for centralised card personalisation, including laser engraving, industrial inkjet printing, overlay lamination, and chip encoding. PowerPerso DLE - Decentralised Card Personalisation With the PowerPerso DLE you get a compact device for decentralized personalisation of ID documents. The high-quality laser engraving technology combined with a contact, contactless or Dual Interface encryption method for personal data offers you maximum security for highly secure ID documents. Pearl ID - Centralised Card Personalisation Pearl ID - Centralised Card Personalisation The Pearl ID is a fast and modular personalisation system for all kind of personalisation tasks with unrivalled...

Request for a quote

PAUL LEIBINGER GMBH & CO. KG

Germany

The JET3up PI is a pigment ink printer primarily used for cables and many other products with dark backgrounds. Data on dark surfaces such as cable must be printed with bright inks. But those present a major challenge for conventional inkjet printers because the pigments in contrast inks settle out. But not with the JET3up PI! The industrial inkjet printer has a unique stirring device that keeps the pigments in motion, thus keeping the ink in the printer always ready for use. This way LEIBINGER guarantees maximum print quality and highest reliability even for the use of pigmented inks. With the automatic nozzle seal "Sealtronic" in the JET3up MI, LEIBINGER can guarantee that the ink does not dry, even after long-term shut-downs. When production stops, the gutter and the nozzle form an airtight circuit: No ink may leak from the circulation and no air can come in. Even after long downtimes LEIBINGER inkjet printers are ready to print within a minute – without cleaning cycles.

Request for a quote

PAUL LEIBINGER GMBH & CO. KG

Germany

The LEIBINGER JET3up is an extra flexible inkjet printer and is therefore suitable for conventional as well as for complex demands in product marking and coding. Over 800 practical functions, numerous options, a wide range of equipment and expanded computer software solutions are available for the users. Possible are up to 5-line print jobs and a print quality up to 32 drop resolution. With the automatic nozzle seal "Sealtronic" in the JET3up, LEIBINGER can guarantee that the ink does not dry, even after long-term shut-downs. When production stops, the gutter and the nozzle form an airtight circuit: No ink may leak from the circulation and no air can come in. Thus, the ink remains liquid as in a closed can of lacquer and the inkjet printer is always ready for use. Even after long downtimes LEIBINGER inkjet printers are ready to print within a minute – without cleaning cycles.

Request for a quote

PAUL LEIBINGER GMBH & CO. KG

Germany

The JET2neoS was developed specifically for smaller fonts and higher production speeds. The JET2neoS is equipped with all the advantages of the JET2neo series but features a smaller 60µ nozzle. This allows the CIJ printer to print considerably faster and finer than the JET2neo. The JET2neoS is tried-and-tested in the industrial marking of extrusion parts, food and drink packaging and plastics, among other uses. With the automatic nozzle seal "Sealtronic" in the JET2neoS, LEIBINGER can guarantee that the ink does not dry, even after long-term shut-downs. When production stops, the gutter and the nozzle form an airtight circuit: No ink may leak from the circulation and no air can come in. Even after long downtimes LEIBINGER inkjet printers are ready to print within a minute – without cleaning cycles.

Request for a quote

PAUL LEIBINGER GMBH & CO. KG

Germany

Whenever a lot of information must be printed on a small area or if the product code should be as discreet as possible, the JET3up MI is the right choice. The small character inkjet printer with an extra fine nozzle is suitable for micro prints with a height up to 0.7 mm. With the automatic nozzle seal "Sealtronic" in the JET3up MI, LEIBINGER can guarantee that the ink does not dry, even after long-term shut-downs. When production stops, the gutter and the nozzle form an airtight circuit: No ink may leak from the circulation and no air can come in. Thus, the ink remains liquid as in a closed can of lacquer and the inkjet printer is always ready for use. Even after long downtimes LEIBINGER inkjet printers are ready to print within a minute – without cleaning cycles.

Request for a quote

PAUL LEIBINGER GMBH & CO. KG

Germany

The stainless steel cabinet of the LEIBINGER JET3up PRO has the protection class IP65 and is dust proof and protected against spray water. Also, the solvent resistant touch screen is durable and easy to clean. Thus, the industrial inkjet printer is ideal for the food and beverage industry and all other industries where strict hygiene regulations are applied. With the automatic nozzle seal "Sealtronic" in the JET3up PRO, LEIBINGER can guarantee that the ink does not dry, even after long-term shut-downs. When production stops, the gutter and the nozzle form an airtight circuit: No ink may leak from the circulation and no air can come in. Thus, the ink remains liquid as in a closed can of lacquer and the inkjet printer is always ready for use. Even after long downtimes LEIBINGER inkjet printers are ready to print within a minute – without cleaning cycles.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ASTRONOVA GMBH

Germany

At GetLabels we have spent years developing and manufacturing inkjet materials for aqueous dye and pigment ink that can be used in all aqueous type inkjet printers from leading manufactures. The Top-Coating is responsible for brighter and more vibrant color. Without an inkjet receptive top-coat your printed output will appear dull and oversaturated with loss of resolution and contrast. Inkjet coating also allows for printing on a multitude of different material types including textured paper to gloss synthetic PET. Our label materials are tried and true. We have successfully supported applications and requirements in the Food and Beverage, Pharmaceutical, E-Juice and Chemical industries just to name a few. Whatever requirement your application needs we have the solution for you. Do not settle for material that is not suited for your inkjet printer - contact us if you have questions on your specific application or have special requirement needs. We are up for the challenge!

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec is a technical services provider that develops and produces electronic assemblies and systems according to customer-specific requirements – from the idea to the finished product. Efficient production processes and reliable execution of the overall implementation are characteristic for RAFI Eltec. As a result of our many years of experience in energy measurement technology and in radio and network applications, we have accumulated unique production and testing expertise. This is also naturally to your advantage in regard to the final assembly of your devices. Final assembly - Assembly presses and screw fittings - Ultrasonic welding - Adhesive robots - Semi-automatic and fully automatic assembly - Automated testing - Laser or inkjet printing technologies - Leak tests - Box build You can rely on support from the right contact partner for you – whether you are approaching us for the first time or during the production process.

Request for a quote

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Design features: solid construction Longitudinal sealing rotary foil wrapping head Main shaft drive frequency-controlled three-phase drive Rotary shear cut knife Film removal control Product insertion control continuous product transport through the folding switches continuously working forehead sealing quick format adjustment Protective doors made from Makrolon, relieved of gas pressure springs PLC control Additional devices: Tear-off thread with tip cut Photoelectric print control Marking printing devices Coding (inkjet / laser) two film rolls automatic reel change Brochure and sample inserts external control devices Vibration equalization for granular contents Roller and belt leveler for powdery products Height sensing and ejection station for container completeness control Processing of heat sealable paper Discharge stack and turning device full-surface, double-sided face sealing oversized film roll Servo drives Machine mobile

Request for a quote

PETRI VERPACKUNGSTECHNIK GMBH

Germany

Design features: solid construction Longitudinal sealing Main shaft drive frequency-controlled three-phase drive Paper cutting knife Film removal control Product insertion control intermittent product delivery clocked forehead sealing frameless protective doors made of 15mm Makrolon PLC control Additional devices: Tear-off thread with tip cut Photoelectric print control Marking printing devices Coding (inkjet / laser) two film rolls automatic reel change Brochure and sample inserts external control devices Vibration equalization for granular contents Roller and belt leveler for powdery products Height sensing and ejection station for container completeness control Processing of heat sealable paper Discharge stack and turning device full-surface, double-sided face sealing oversized film roll Servo drives Machine mobile

Request for a quoteResults for

Inkjet printing - Import exportNumber of results

22 ProductsCountries

Company type

Category

- Marking - diverse products (6)

- Chemicals and pharmaceuticals - packaging machinery (4)

- Bar codes - printing machines (2)

- Crate packing machinery (2)

- Electric and electronic components - machines for manufacturing (1)

- Electrical & Electronic Components (1)

- Labelling machines (1)

- Labels - stationery (1)

- Metallurgy and iron and steel industry - machinery and installations (1)