- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial parts

Results for

Industrial parts - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The pin screw, which is made by stainless steel, application in many kinds fileds, such as valve industrial,construction manufacturing industry and so on.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are little screw used in construction industry,machinery parts ,and so on ...

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

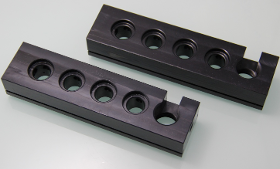

Aluminium CNC milling part in black anodize finish Tolerance:+/-0.05mm, Critical holes and threads Surface rougness:Ra1.6 CNC Machining parts, Machining in Aluminium stainless steel,brass,copper, titanium,POM and so on. Aluminium housing, Blocks, flanges, valve seat, supporter CNC Turning parts ,Machining in Aluminium stainless steel,brass,copper, titanium,POM and so on.

Request for a quote

BORNEMANN GMBH

Germany

Shaping dies adopt a central role in many areas of the manufacturing and processing industries. They are of particular significance in the sheet-processing industry. We produce these parts in accordance with your requirements – also in small series. Contact I have read and agree to the privacy policy. *Pflichtfelder

Request for a quote

WEBER GMBH & CO. KG, KUNSTSTOFFTECHNIK UND FORMENBAU

Germany

From the initial concept to a safe and reliable series delivery, our customers get everything from a single source. They benefit from our decades of experience in manufacturing interiors as well as exteriors for the automotive industry.

Request for a quote

PRESSTECK S.P.A.

Germany

For our customers in the automotive and housing industry, we produce deep-drawn stainless steel pots with an integrated axle as a monobloc component. These are used in water pumps for electric vehicles. Our customer from the automotive industry needs pots with an integrated axle that holds a rotor. Up to now, the pot and axle have been joined in a centred manner by means of welding. The customer's wish was to produce a one-piece component to avoid welding. Deep drawing is the ideal technology for this. The size of the component required larger presses than were previously available. Therefore, we first developed tools as prototypes for larger presses on behalf of the customer. After practical tests at the customer's premises as well as at the end customer's, our client decided on a tool that was ideally suited for the production of the component in series.

Request for a quote

ORBIS EUROPE

Germany

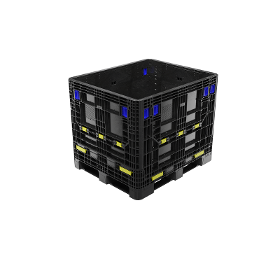

ORBIS reusable bulk containers are designed to protect and transport heavy parts in automotive and industrial applications. Engineered for rugged applications, the plastic bulk containers are extremely robust and offer comprehensive product protection over a long service life. The 1200 x 1000 plastic bulk containers are available in multiple heights for increased packing density. The collapsible design with a return ratio of up to 1 : 3 reduces the shipping of air during return transport to a minimum. Key features: - manufactured from recycled material - multiple heights, access door and bottom configurations - durable all-plastic design - improved workplace safety - easy, on-site repair and part replacement - 100% recyclable

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Stampings (and stamped parts) are versatile and you find them in a wide range of applications for many different industries. Lesjöfors delivers stamped parts from our standard program as well as customized solutions.

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

Drop-forgings of carbon and alloyed steel, nickel, duplex, titanium and superalloys like Monel® or Hastelloy®, Inconel®, Incoloy® for pressurized components like forged valves or valve parts like bodies and yokes or bonnets, flanges for boiler systems, fittings for piping, non-corroding parts for shipbuilding, marine technology, slings and lifting gear, hooks, eyebolts, nuts, chain links, military vehicles, transportation and defense. Every nut, bolt, and screw - forgings for harsh environments: forged valve bodies, bonnets, yokes and flanges, pipe connections, pressure applications like boiler parts, hoists, chain links, eyebolts, hydraulic components, corrosion and acid-resistant parts for chemical and fertilizer industries, as well as shipbuilding and drill equipment. Pressure equipment and nuclear power (valves, boilers, piping): PED 2014/68/EU, AD 2000-W0, ASME/ASTM, KTA, RCC-M Shipbuilding and maritime industry ABS, BV Marine & Offshore, DNV, LR Shipping, ClassNK

Request for a quote

NAGLER NORMALIEN GMBH

Germany

Copper drawing parts for industrial applications

Request for a quote

PERO AG

Germany

The parts are immersed in the wet medium. Dirt is dissolved from the surface by the heated wet medium. By moving the parts while immersed, cleaning is assisted by a mechanical effect. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quote

PERO AG

Germany

The wet medium is sprayed through nozzles onto the surfaces of the parts. Particles are removed from the parts by kinetic energy, and then washed away. The cleaning result is primarily determined by the position and shape of the nozzles, the spray pressure and the volume of media applied to the parts. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quote

KLN ULTRASCHALL AG

Germany

The machine of series KT can be applied universally. It is designed for the industrial part cleaning. Application fields: metal degreasing, electrical industry, optical industry, medical technology, maintenance and service etc. The compact design of the machine as 3-tank system guarantees a high cleaning quality together with space-saving location. The basic version consists of a heated ultrasonic tank (tank 1) and heated cascade rinsing (tank 2 and 3). Additionally a separate dryer corresponding to the size of the compact unit can be made available. The tanks are incorporated in a solid frame. Optionally a stainless steel base frame can be delivered. Armatures, tank and frame are made of stainless steel. All valves can be easily operated at front of the machine. All electrical operating elements are on the front of the machine. They are each assigned to the tanks.

Request for a quote

PERO AG

Germany

In industrial parts cleaning, wet media are used in 70 to 90 % of all cleaning processes. Wet media include aqueous solutions – similar to detergents we use to wash our dishes or laundry – as well as nonaqueous solvents. For each cleaning task, project engineers must choose the best wet medium, taking into account ecological and economic considerations. Workpieces and parts are produced in finetuned production processes that often require the use of special consumables and process chemicals. Parts are generally made from specific materials, and their contamination after machining is determined by the processes they have undergone. When assessing the environmental impact of cleaning media, one sometimes comes to surprising conclusions. First of all, the energy input and use of resources must be assessed.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Industrial parts cleaning with the Perkute Frontloader Series The PERKUTE parts cleaning machines from the Frontloader series are specially conceived for the simple and effective cleaning and de-greasing of both, high-volume components as well as heavy components, as well as those with complex and sensitive geometries. The workpieces are loaded through crane charging or with loading trolleys or loading ramps onto the product slide and then into the washing system. The stainless steel frontloader washing machines with their space-saving, compact design, either work with a driven rotating basket or in the case of sensitive parts, with a nozzle pipe system transported by means of a double-chain, with the products being at rest. All the process stages like washing, rinsing (not in the case of the FR Series) and drying take place in the same treatment chamber. A large number of options for preparing the process media leaves almost nothing to be desired.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Industrial parts cleaning with the Perkute Toploader Series The PERKUTE rotating basket cleaning machine from the Toploader series is used wherever effective and inexpensive cleaning of parts of any kind is necessary. The rotating basket, designed for large weights, is powered by means of a low-wear friction wheel drive and the aqueous cleaning in the spray process takes place by means of a nozzle pipe system with special flat-spray nozzles that is arranged on 3 sides. A powerful washing pump supplies the system with the necessary pressure and volume flow. The parts cleaning machines, made completely of non-rusting special steel, istinguish themselves by their compact and robust construction as well as simple handling. They are mobile to deploy and designed to be space-saving. Customisation for individual cleaning tasks can be optimised through a comprehensive range of accessories.

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Our custom blow molded parts such as containers, air conduction tubes, connection tubes and drainage tubes are 3D blow molded, suction blow molded and manipulated by a robot (3-D Roboter Blow Moulding Machine). They are 100 percent leak-proof and guarantee consistent wall thickness. Since the blow molds are developed by and tailored to customer specific requirements, a perfect fit is guaranteed, the number of assembly steps is reduced, weight is reduced and the risk of leakage is minimized. Available materials / maximum operating temperature: PE / -40°C up to + 70°C PP / -40°C up to +105°C Dimensions: max: 900x500x300mm min: 50x20x100mm eight/pc.: 10-3.000 Gramm diameter: min. 8-10 mm Application: Industrial applications, such as home appliances, air conditioning, medical technology, etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our compacting presses for titanium sponge are used in numerous dierent industries. Component parts made of titanium and titanium alloys play an important role in the aerospace industry for plane engines or highly stressed parts such as the undercarriage or supporting structures of an aircraft. Titanium is also indispensable for orthopedic applications as well as the chemical industry. The compression speed of our presses, which can be precisely adjusted to the product, oers operators highest repeat and size accuracy. Features Press capacity < 80 MN single or double-acting design automated tool change concept remote access for service support

Request for a quoteResults for

Industrial parts - Import exportNumber of results

19 ProductsCountries

Company type

Category

- Cleaning machines, industrial (4)

- Automation - systems and equipment (1)

- Forming - steels and metals (1)

- Milling - machine tools (1)

- Aerosol valves (1)

- Boxes, plastic (1)

- Foundries - copper, bronze and brass (1)

- Hoses, pipes and tubes - plastic (1)

- Hot forming (1)

- Import-export - steels and metals (1)

- Presses, hydraulic (1)

- Roofing - works (1)