- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hydraulic units

Results for

Hydraulic units - Import export

HYDRAULIK SCHWERIN GMBH

Germany

Special units 1000 to 50000 liter tank volumes, standard aggregates, motor / pump assemblies, valve stands, storage stations, filter cooling circuits, lubrication systems, engineering and delivery compl. tube sets

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Lifting height up to 1,800 mm Load capacity up to 6000 kg The lifting tables in the Middle Class are available in any preferred size. Thanks to the modular design (base frame, scissor arms, hydraulic unit, platform sizes and options) they can be easily adapted to individual needs, taking into consideration also characteristics of loading/unloading areas. Benefits Infinitely variable hydraulic height adjustment Extensive project know-how Production according to German quality standards

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

The truck dock from Lödige facilitates the loading and unloading of air cargo units onto and off trucks. Equipped with a hydraulic lifting unit and a vertical shift function, the truck dock brings conveyor elements into line with the truck loading ramp. ULDs or pallets are transferred horizontally by a powered roller conveyor. Depending on requirements, the conveyor can be replaced or combined with other technologies such as a ball deck or castor deck. A moving version of the truck dock is also available.

Request for a quote

LÖDIGE INDUSTRIES GMBH

Germany

Cost-efficient transport between floors The vehicle lift CARRICO is an interesting alternative to the TRAFFICO when lower lifting heights and less frequent use are needed. The CARRICO has been type-tested in accordance with the EU Machinery Directive 2006/42/EC. The conveying speed is limited to 0.15 m/s. Furthermore, this car lift is delivered with automatic sliding doors and cabin equipment designed for the transport of vehicles and passengers. Functions of the components Door type: automatic sliding door (depending on the cabin width - 4- or 6-leaf) Entrances: front only / through Control: Control unit with micro-processor with extensive control functions Drive: Submersible hydraulic unit incl. screw spindle pump Advantages Saves on construction space as no ramp required Especially suitable for narrow shafts Cost-effective way to transport cars Easy to operate, manual hinged doors

Request for a quote

SITEMA GMBH & CO KG

Germany

KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Electric Locking Unit The electric Locking Unit KFE is used as a stepless locking device on round rods and holds axial forces in both load directions without axial play. It is used where hydraulic or pneumatic solutions are not possible. The holding force is created by the proven spring-operated clamping system as it is used in SITEMA’s hydraulically or pneumatically operated Locking Units. At a drop of the control voltage or in case of failure of the electric supply, the Locking Unit KFE clamps automatically. Therefore, it is also suitable for use in safety relevant applications. To operate the Locking Unit KFE, a supply voltage of 24 V and a control signal for the input command “clamp/release” are sufficient. The Locking Unit is self-monitoring and provides output signals...

Request for a quote

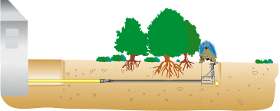

TRACTO-TECHNIK GMBH & CO. KG

Germany

For small diameter supply pipes where working is only possible with a winch cable One system for pipe replacement, single pipe bursting and pipe string relining Pipe renewal out of a keyhole possible Application up to 60 m section length at almost constant pulling force Compact modular system for application out of small pits (L x W: 1,20 x 1,00 m) or out of a keyhole (650mm diameter) Fast set up, easy transportation Simple jobsite compatible construction Driven by a hydraulic unit or alternatively via a mini excavator hydraulics Application of winch cables of different diameters by simply exchanging the cable Operation outside the construction pit using a rigboom a and a support frame high working quality, long service life low investment and low operation costs

Request for a quote

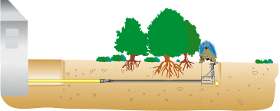

TRACTO-TECHNIK GMBH & CO. KG

Germany

For small diameter supply pipes where working is only possible with a winch cable One system for pipe replacement, single pipe bursting and pipe string relining Pipe renewal out of a keyhole possible Application up to 60 m section length at almost constant pulling force Compact modular system for application out of small pits (L x W: 1,20 x 1,00 m) or out of a keyhole (650mm diameter) Fast set up, easy transportation Simple jobsite compatible construction Driven by a hydraulic unit or alternatively via a mini excavator hydraulics Application of winch cables of different diameters by simply exchanging the cable Operation outside the construction pit using a rigboom a and a support frame high working quality, long service life low investment and low operation costs

Request for a quote

GSW SCHWABE AG

Germany

shock dampening for low operating noise levels absolutely sturdy and warpresistant body design with heavy doublepost guides to smoothly cut even toughest materials with adjustable blade clearance for a most precise cut at any thickness very precise blades made of special steel high operating safety through material guide at entrance and protective cover springactuated hold down clamp (from 250 mm stock width) top/bottom dead center control to monitor blade position counter control mounting bracket hydraulic power units in different sizes electrical control

Request for a quote

GSW SCHWABE AG

Germany

shock dampening for low operating noise levels thanks to a heavy overall frame and the sturdy, warpresistant design with heavy doublepost guides even toughest materials can be cut smoothly with adjustable blade clearance for a most precise cut at any thickness very precise blades made of special steel high operating safety through material guide at entrance and protective cover springactuated hold down clamp (from 250 mm stock width) top/bottom dead center control to monitor blade position counter control mounting bracket hydraulic power units in different sizes electrical control

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

We install the necessary hoses between hydraulic power units and press cylinders. We also create piping and circuits for thermal oils and cooling water.

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Hydraulic and pneumatic cylinders, Presses, Shock absorbers, Fittings, Controls, Piston and plunger pumps, Mobile hydraulics, Injection units

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Hydraulic and pneumatic cylinders, Presses, Shock absorbers, Fittings, Controls, Piston and plunger pumps, Mobile hydraulics, Injection units

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Hydraulic and pneumatic cylinders, Presses, Shock absorbers, Fittings, Controls, Piston and plunger pumps, Mobile hydraulics, Injection units

Request for a quote

AQUACHEM GMBH SEPARATIONSTECHNIK

Germany

The BC-series impresses with its simple and robust technology, while at the same time offering the user many features to simplify work. The optionally available semi-automatic plate shifting allows the user to shift the filter elements conveniently. The hydraulics are controlled via the HMI control system with touchscreen. This allows any feeding pump of your choosing to be integrated and controlled. There are plates available in the formats 800, 1,000 and 1,200 mm, allowing for filtration surfaces of up to 178 m². Thanks to the gasketed design, a clean environment is ensured, even during the internal flushing of the filter elements with aggressive media. The individual discharge manifold enables many functions such as displacement air drying, turbid flow, clear flow, flushing and also cake washing. The standardised hydraulic unit is used in both the BC-series and the AF-series.

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

Can be dismantled in three parts so can be used from out of the building without a core drill, i.e. for FTTX, gas connections Pneumatically driven hammer bore head assembly is ideally suited for alternating soils. If the hammer bore head meets with resistance (larger rock inclusions, solid rock, rubble deposits or brickwork), the hammer effect is activated automatically. The complete system with hydraulic power unit and mixing unit MA09 can be placed on a small trailer for safe transportation. Can be dismantled Portable Can be applied from out of a building

Request for a quote

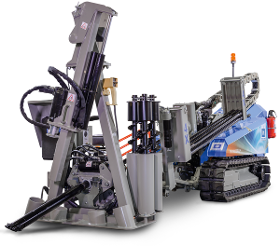

TRACTO-TECHNIK GMBH & CO. KG

Germany

Kubota diesel engine with 28 kW driving power Control station with easy to survey control panel Multifunctional joystick Hydraulic anchor bore unit swivels in three positions Remote control Drill rod magazine with 32 drill rods for 48 m bores Stabiliser blade, rubberised steel track undercarriage

Request for a quote

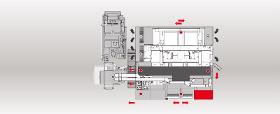

PRESSTA EISELE GMBH

Germany

0 – 300 mm adjustable pneumatic material feed and digital display Vertical hydraulic punching unit to the right of the saw blade Power 200 KN Punching tools according to profile shape Aluminium profile – finished Cut to length Vertical punching Up to 8 profiles in one operation cycle Cycle time from 13 s / 1,63 s each piece Layout of punching tools for multiple profiles Quick change punching tools according to the profile shape Pneumatic material feed 8 profiles at once Special shaped quick change support Clamps according to profile shape – changeable Hydraulic punching unit Power 200 KN, stroke 20 mm Cycle spray mist device for each die and for the saw blade

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELKON GMBH

Germany

These pumps have been designed according to the most difficult conditions and heavy work.They are high performance pumps with diesel engine and S Valve System. Both models can deliver concrete up to 100 meters vertically or 300 meters horizontally. Both ELKOPOMP S45 & ELKOPOMP S60 are equipped with axle and tires. Thus, it can be easily towed and transported to required points. Moreover, the concrete delivery pipes can be easily assembled and become ready to deliver concrete. The brand of the hydraulic control unit used in ELKON Trailer Type Concrete Pumps is BOSCH-REXROTH (Germany) and the system is an open-circuit hydraulic system. ELKON Trailer Type Concrete Pumps are equipped with high quality and chrome coated concrete delivery cylinders. The system can easily regulate itself with power regulation when it delivers the concrete to higher distance by means of hydraulic pump which has variable flow, power regulation and axial piston.

Request for a quote

ELKON GMBH

Germany

These pumps have been designed according to the most difficult conditions and heavy work.They are high performance pumps with diesel engine and S Valve System. Both models can deliver concrete up to 100 meters vertically or 300 meters horizontally. Both ELKOPOMP S45 & ELKOPOMP S60 are equipped with axle and tires. Thus, it can be easily towed and transported to required points. Moreover, the concrete delivery pipes can be easily assembled and become ready to deliver concrete. The brand of the hydraulic control unit used in ELKON Trailer Type Concrete Pumps is BOSCH-REXROTH (Germany) and the system is an open-circuit hydraulic system. ELKON Trailer Type Concrete Pumps are equipped with high quality and chrome coated concrete delivery cylinders. The system can easily regulate itself with power regulation when it delivers the concrete to higher distance by means of hydraulic pump which has variable flow, power regulation and axial piston.

Request for a quote

ECOROLL AG WERKZEUGTECHNIK

Germany

The tools HGx-1, -2, -4, -11 machine bores, complex inner contours and fillets. Depending on the pressure supply, tools types HGx-5, -7 (integrated) and HGx-9, -10, -19 (external) machine rotationally symmetrical contours. HGx-20 and -29 are intended for narrow cylinders and thin-walled components. As accessories, ECOROLL offers hydraulic units, rotary units for the connection of turret machines. Note: Tools are listed as HGx-y, where x indicates the ball size and y the design version (e.g. HG6-2 holds a ball with ∅ 6 mm and is designed for machining cylindrical bores).

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

BEST POSSIBLE ERGONOMICS & EFFICIENCY OF MAINTENANCE: FOR OPERATORS No platform required for machine loading and operating area Pivotable main control panel with good visibility into the work area FOR MAINTENANCE & SERVICE Sliding doors on the back provide generous central maintenance access to the machine, doors in the setup room can be opened wide Central and easily accessible media supply, hydraulic unit and maintenance access for A and W axis through movable housing segment

Request for a quote

KAUP GMBH & CO KG

Germany

1000-fold proven components of the KAUP modular design combined in a particular way: these make up KAUP Stationary Material Handling Equipment. They consist of project related system solutions which can be integrated in every production process. Our devices have already been implemented for handling bagged products such as sugar or cement. But also in goods handling and storage of consumer goods and beverages, when turning sheet metal or paper sheets for processing on both sides, our application orientated devices are in great demand. The majority of our equipment is driven by a hydraulic power unit. They can be controlled automatically, semiautomatically or manually and so optimally adjusted to the customer requirements.

Request for a quote

FATH GMBH

Germany

Lift castor system for a fast and flexible placing of plant and machinery or assembly tables; gear transmission ratio: 10:1 Max. Load: 500 kg per lifting unit Material: Housing: Die-cast aluminum with PTFE bearing Roller: Plastics PA with ball bearing Roller housing: Zinc plated steel Set: 4 lifting units 1 hydraulic drive unit 4 hydraulic pipes at each 3 m, pre-filled Extras: Other sets on request

Request for a quote

IPR GMBH

Germany

Technical data ED 100 To drive the nitrogen charging apparat «SL 230 SLG» and all crimping and cutting tools. Designed for continuous use Maximum pressure: 850 bar Delivery volume: up to 0,8L/min Fitting to all tools with oil demand up to 700cm³ Shiftable automatic detection of pressure requirement with switching off at the Essential working pressure from 20 to 850 bar Built in pressure sensor for improved functionality and enhanced adjustment Inching function for interrupted tool infeed Robust housing, operating elements and coupling are built in secured under body top Weight: ca.14 kg Supplied with Hydraulic power unit 3m Remote control 3m Power charger adjustable shoulder strap instruction manual

Request for a quote

IPR GMBH

Germany

Technical data UNI FUTURE with pressure transducer Pressure needs detection with switch-off upon reaching the required working pressure of 20 bis 850 bar Suitable for all tools with a oil flow to 700cm³ With built-in-pressure sensors for enhanced features and advanced settings Jogging for intermittent tool feed Power stepless adjustable, short time possible to 1,2 kW For Network and battery (24/230V) Powerful Li-Ionen battery 24 V 4,8 Ah The unit is designed so that the battery capacity is sufficient for one working day. Integrated charger Energy savin mode – Unit switches off 10 minutes after the last activity, or to low battery charge Shutdown at idle after the working cycle, prevents tool damage and saves energy Robust plastic housing Controls and coupling are set back behind the front edge of the housing Flow rate: automatically adjust to 1l/min Size L/B/H: 215 x 165 x 220mm (Handle height 40mm) Weight: ca. 6,9 kg SUPPLIED WITH Hydraulic power unit 3m Remote control 3m Power charger adjustable shoulder strap instruction manual

Request for a quote

IPR GMBH

Germany

Technical data UNI FUTURE 2050 SCU Also as a drive towards a cutting system Automatic detection with switch-off pressure required for achieving the required operating pressure of 20 bis 700 bar Suitable for all tools with a oil flow to 700cm³ With pressure gauge (1000 bar) and ground connector on the front side With pressure sensors for advanced features Detection tool with speed adjustment to (tool speed 10mm/sec) BG provision to fulfill Optional jogging for intermittent tool feed. Power adjustable,short time possible to 1,2 kW ch Network and battery (24/230V) Powerful Li-Ionen Battery 25,2 V 4,8 Ah The unit is designed so that the battery capacity is sufficient for one working day. Integrated charger Energy spaving mode– 10 minuets after the last activity or to low battery condition, switches off the unit Shutdown at idle after the working cycle, prevents tool damage and saves energy Robust plastic housing Controls and coupling are set back behind the front edge of the housing Flow rate: automatic adjustment to 1l/min Size L/B/H: 222 x 168 x 229mm (Handle height 40mm) Weight: ca. 6,9 kg Supplied with Hydraulic power unit 3m Remote control 3m Power charger adjustable shoulder strap instruction manual

Request for a quote

IPR GMBH

Germany

Technical data cube with pressure transducer and lock valve Pressure needs detection with switch-off upon reaching the required working pressure of 20 bis 850 bar Suitable for all tools with a oil flow to 700cm³ With built-in-pressure sensors for enhanced features and advanced settings Jogging for intermittent tool feed Power stepless adjustable, short time possible to 1,2 kW For Network and battery (24/230V) Powerful Li-Ionen battery 24 V 4,8 Ah The unit is designed so that the battery capacity is sufficient for one working day. Integrated charger Energy savin mode – Unit switches off 10 minutes after the last activity, or to low battery charge Keeps the pressure of max. 850 bar upon actuation of the stop valve Robust plastic housing Controls and coupling are set back behind the front edge of the housing Flow rate: automatically adjust to 1l/min Size L/B/H: 215 x 165 x 220mm (Handle height 40mm) Weight: ca. 6,9 kg The lock valve for pipe crimping tools prevents reduction of oil pressure in the tool. So it is possible to hold hydraulic pressure over not time limited space. Supplied with Hydraulic power unit 3m Remote control 3m Power charger adjustable shoulder strap instruction manual

Request for a quoteResults for

Hydraulic units - Import exportNumber of results

60 ProductsCountries

- Germany (60)

- Bonn, Düsseldorf and North Rhine and Westphalia (15)

- Frankfurt am Main and Hesse (1)

- Hamburg and region (1)

- Hannover and Lower Saxony (13)

- Kiel and Schleswig-Holstein (1)

- Mainz and Rheinland-Pfalz (2)

- Munich, Nuremberg and Bavaria (17)

- Schwerin and Mecklenburg-Vorpommern (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (7)

- Weimar and Thuringia (2)

Company type

Category

- Presses, hydraulic (8)

- Folding machine tools (7)

- Machine tools - metal machining (5)

- Machine tools - metal shaping (3)

- Sealing rings (3)

- Cylinders, hydraulic (2)

- Concrete mixers (2)

- Gas and oil - exploitation (2)

- Machine tools, metal machining - parts and accessories (2)

- Metal straightening machines (2)

- Hydraulics systems (1)

- Hydraulic equipment (1)

- Filtering equipment and supplies (1)

- Bending machine tools (1)

- Construction - Machines & Equipment (1)

- Conveyor systems (1)

- Coupling, pneumatic (1)

- Flanges (1)

- Forklift trucks (1)

- Hydraulic brakes (1)