- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hydraulic fluids

Results for

Hydraulic fluids - Import export

SITEMA GMBH & CO KG

Germany

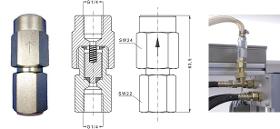

Mechanical Safety Catcher KRM Electric Locking Unit KFE Special customer requirements Applications Overview Presses Machine Tools Automatization + Feeders Lifting Gear + Mobile Hydraulics Production Technology Special Machinery CAD Download Contact Auto Bleeder The SITEMA Auto Bleeder has been specially designed for the use with a SITEMA clamping head. It makes sure that the hydraulic system is constantly bled. Air bubbles in the hydraulic fluid might combust spontaneously under certain conditions (so-called Diesel effect). As a consequence, seals and sealing surfaces can be damaged, causing leakages. Clamping heads are especially susceptible for this phenomenon, as they have only a very small hydraulic volume and are not flushed through at each activation. Air can therefore easily accumulate in the clamping head. This is the reason why the usual initial bleeding at commissioning is often not enough, especially when the line leading to the clamping head points upwards...

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

MBS hydraulic cylinders of the MZR-1006 series are block-type differential cylinders for use in mold, tool and jig construction. The cylinder connection is very variable due to various mounting holes on the housing and piston rod. Connections with connection holes are available for pipe connections to BSPP ISO 1179-2. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of the types H, HL and HLP according to DIN 51525-1. If you have any questions about areas of application or other options, we are happy to answer them. Download the data sheet for detailed information

Request for a quote

IDG-DICHTUNGSTECHNIK GMBH

Germany

Kaplan turbines are typically used for river power plants on calm waters. The blade angle runner blades (Kaplan blades) is adjustable. The pressure of the water flow, which is controlled by the guide vanes of the upstream wicker gate, can then be efficiently converted into energy. The bidirectional MANOY® system seal WP, type 444, in the form of a continuous ring was developed to protect the hydraulic adjustment device and prevent hydraulic fluid leakage. Type 449 is particularly useful for maintenance work because rather than being continuous in circumference, the seal is open and has a guide blade.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of temperature-stressed machine parts, e.g. rolling bearings, friction bearings, slideways, chains, rollers or moving parts in hot forming, heat treatment or drying Dry lubrication, e.g. of kiln and rack-truck bearings, bearings of pouring ladles, converters or hot-air blowers at temperatures over 250°C Lubrication of plastic and rubber at normal temperature when the materials concerned are not resistant to mineral oil Advantages and benefits Highly effective due to the strong affinity of the MoS₂ for metals Extremely low friction at highest loading capability Broad range of applications at temperatures up to 200°C as paste, over 200°C to 450°C as dry lubricant Resistant to water, fuels and lubricants, chemicals and hydraulic fluids For best adhesion, clean the threads and sliding surfaces from dirt and other lubricants. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner.

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1004 series are synchronized cylinders for use as actuating and control cylinders. All cylinders work with low friction and run stick-slip-free. The connection is made via a head flange attachment and a threaded attachment on the piston rod. For flexible use, fittings for pipe fittings according to BSPP ISO 1179-2 and venting connections are available on both sides. Lift and piston rod protrusion are also variable selectable. Our cylinders are prepared for use with position sensor and position monitoring. With the exception of the piston rod and the centering surfaces, the entire cylinder is protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of the types H, HL and HLP according to DIN 51525-1. If you have any questions about areas of application or other options, we are...

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1021 series are designed as differential cylinders for applications with high quality requirements in stationary mechanical engineering. All cylinders work with low friction and are characterized by a stick-slip free run. Hub and piston rod protrusions are variable selectable. The cylinder is connected via a head flange mounting with centering shoulder and a threaded shoulder on the piston rod. There are connections for high pressure flanges to SAE 6.000 P.S.I as well as vent holes for a free installation position. With the exception of the piston rod and SAE flange surfaces, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy...

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS standard cylinder series is characterized by a variable and stroke-independent welded construction. Due to the uniform force transitions between the different sizes and the different connection situations, they are often used in the areas of mobile and stationary hydraulics. Cylinder connection is via welded rod ends and bolted radial bearings. Connections with threaded holes for pipe fittings according to BSPP ISO 1179-2 are planned. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the data sheet for detailed information:

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1001 series are differential cylinders for applications with high quality requirements in stationary mechanical engineering. All cylinders work with low friction and are characterized by a stick-slip-free run. Lift and piston rod overhang are variable selectable. The cylinder is connected via a head flange mounting with centering shoulder and a threaded shoulder on the piston rod. There are connections with screw-in holes for pipe fittings to BSPP ISO 1179-2 as well as vent holes for a free installation position. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP in accordance with DIN 51524 / 51525-1. If you have questions about areas of application or other options, we are happy to answe

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1005 series are synchronized cylinders with spring return for use as actuating and control cylinders. The spring characteristic is freely selectable according to customer specifications. Also hub and piston rod protrusion are variable. The cylinder connection takes place via a head flange attachment and a threaded attachment on the piston rod. For flexible use there are connecting pieces for pipe fittings to BSPP ISO 1179-2 and venting connections on both sides. The cylinders are prepared for use with position sensor and position monitoring. With the exception of the piston rod and the centering surfaces, the entire cylinder is protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of the types H, HL and HLP according to DIN 51525-1. If you have any questions about areas of...

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1007 series are synchronized cylinders with pivot pins for robust, high-frequency use in general mechanical engineering. The cylinder is connected via a pivot pin ring, which can be variably screwed to the cylinder tube, and a threaded neck on the piston rod, which is designed for rod ends according to DIN24338 / ISO6982. There are also connection bores for pipe connections according to BSPP ISO 1179-2. Hub and piston rod overhang are variably selectable. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the data sheet for detailed information

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinder MZR-1008 is designed as a discharge cylinder of direct support systems on mobile devices, such as Cranes have been constructed. The integrated position measuring system enables the exact position of the support cylinder to be detected. This is hydraulically fixed in connection with the piped double check valve. The cylinder connection is via plain bearing bushes. There are connecting bores for pipe fittings according to BSPP ISO1179-2 in the valve block. Hub and piston rod overhang are variably selectable. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the data sheet for...

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1002 series are direct support cylinders for vehicle construction. A robust cylinder connection is made possible by welding blocks. The support plates are ± 15 ° swivel. The cylinder connections have threaded holes for pipe connections according to BSPP ISO 1179-2. Hub and piston rod overhang are variably selectable. Control of the cylinders is possible on both sides via integrated hydraulically operated check valves in plate construction. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the data sheet for detailed information:

Request for a quote

MBS-HYDRAULIK GMBH & CO KG

Germany

The MBS hydraulic cylinders of the MZR-1019 series are lightweight cylinders where weight is of crucial importance. They were designed for the areas of mobile hydraulics, crane and aerial work platform construction. All cylinders work with low friction and are characterized by a stick-slip-free run. Lift and piston rod overhang are variable selectable. The cylinder connection is via plain bearing bushes. Connections are provided on the valve plate or a control block, which are flanged to the cylinder via welded pipes, in accordance with DIN EN 280. With the exception of the piston rod, all surfaces are protected against corrosion with a black primer. On request alternative surface treatments are possible. The surface of the piston rod is hard chromed, ground and polished. The cylinders are suitable for hydraulic fluids of types H, HL and HLP according to DIN 51524/51525. If you have questions about areas of application or other options, we are happy to answer them. Download the...

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors react when a filling level is exceeded or falls below a limit. Aqueous mediums like coolants, AdBlue®, fresh water, waste water, bilge water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Since they contain no mechanical moving parts, their function will not be influenced by dirt particles or other influences. No electrical current is sent through the medium via an electrode with BEDIA sensors, an electrolysis of the medium is not possible. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that arises when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator, causing it to oscillate. Then this signal is processed by a microprocessor-based evaluation circuit.

Request for a quote

BEDIA MOTORENTECHNIK GMBH & CO. KG

Germany

BEDIA level monitoring sensors are used to monitor the filling levels of liquids. The sensors detect when a filling level is exceeded or falls below a limit. Water-based liquids like coolants, AdBlue®, fresh water, waste water and oil-based liquids like motor oils, hydraulic oils, fuels and brake fluids can be monitored. Operating Principle The function of the sensor is based on the capacitive principle. It detects the change in capacitance that occurs when an electrode surrounded by air is immersed into a liquid medium. This change in capacitance at the electrode of the sensor excites an oscillator. This signal is processed by a microcontroller-based evaluation circuit which activates or deactivates an output stage. Types of Media The level monitoring sensors are designed for two different media types: For electrically conductive liquid media with relative permittivity within a range of εr 35 … 85 (water, coolant, water/glycol mixture) For electrically non-conductive liquid media

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Designed as tubular support, vibration and noise absorber and protection element for rigid return lines entering the hydraulic reservoir Features ▪ For all commonly available Metric and imperial pipe and tube diameters from 6 ... 42 mm and 1/4 ... 1-1/2 in ▪ Easy installation ▪ Chemically resistant against oil and solvents Materials ▪ Bushing made of Polypropylene (PP) or Thermoplastic Elastomer (TPE) with a hardness degree of 87 Shore-A Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Designed as in-tank suction strainer elements for direct installation into suction lines of pumps; should always be installed below the minimum fluid level of the reservoir Features ▪ Available with female BSP thread (ISO 228) or female NPT thread (ANSI B1.20.1) Materials ▪ Threaded end cap made of glass-fibre reinforced Polyamide (PA) or Aluminium ▪ Lower end cap and support tube made of Steel, zinc-plated ▪ Standard filter material is Stainless Steel Mesh (125 μm); alternative micron ratings of 60 μm and 250 μm on request Consult STAUFF for alternative materials. Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Technical Data ▪ Operating temperature range: -20 °C ... +100 °C / -4 °F ... +212 °F ▪ Integrated bypass valve with an opening pressure of 0,2 bar (3 PSI) to reduce the risks of high-pressure drops that can be caused by contaminated strainer elements or high-viscosity fluids Special sizes, designs, materials and...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The Oil Condition Sensor OCS is designed for continuous monitoring of hydraulic systems. Permanently installed in the system the OCS sensor monitors the condition of hydraulic fluids and lubricating oils in real time, whereby water ingress and oxidation can be detected in time. The OCS sensor is 60 times more sensitive than dielectric sensors on increasing contamination and protects the system from cost-intensive downtimes and reduces machine downtimes. Thanks to its robust construction the OCS sensor can even be used under extreme conditions and temperatures. ▪ Robust construction ▪ ƒƒUsage under extreme conditions with temperatures from -20 °C ... +120 °C /-4 °F ... +248 °F ▪ ƒƒSuitable for use at operating pressures up to 20 bar / 290 PSI Materials ▪ ƒƒStainless Steel (corrosion-resistant Steel) AISI304, 1.4301. Dimensions ▪ ƒƒ90 x 37 mm / 3.54 x 1.46 in Weight ▪ ƒƒ160 g / .35 lbs Sealing Material ▪ FPM (Viton®) Max. Burst Pressure ▪ 20 bar / 290 PSI Media Temperature ▪ -20 °C...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Visual fluid level indication in hydraulic reservoirs with maximum tank pressures not exceeding 2 bar / 29 PSI Nominal Sizes and Designs ▪ 6 nominal sizes from 76 mm / 2.99 in to 305 mm / 12.00 in ▪ Display either undivided (SNA 076 ... 176) or subdivided by strut(s) into 2 (SNA 254) or 3 sections (SNA 305) Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Materials ▪ Housing made of Steel St 12, black powder coating ▪ Sight tube and plugs made of Polyamide (PA) ▪ Sealings made of NBR (Buna-N®) ▪ Scale plate made of PVC Special sight tube materials for improved UV or chemical resistance and use with special media (such as bio-degradable fluids, diesel oils, gasolines, etc.) as well as special sealing materials, e.g. FPM (Viton®), and scale plate materials, e.g. Aluminium, are available on request. Technical Data ▪ IP 65 protection rating: Dust tight and protected against water jets (IP 67 on request) ▪ Operating temperature...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Visual / electrical fluid level indication in hydraulic reservoirs with maximum tank pressures not exceeding 2 bar / 29 PSI Nominal Sizes and Designs ▪ 5 nominal sizes from 127 mm / 5.00 in to 305 mm / 12.00 in ▪ Display either undivided (SNK 127 ... 176) or subdivided by strut(s) into 2 (SNK 254) or 3 sections (SNK 305) Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Materials ▪ Housing made of Aluminium, black powder coating ▪ Sight tube and plugs made of Polyamide (PA) ▪ Float made of Polyamide (PA) ▪ Sealings made of FPM (Viton®) Special sight tube materials for improved UV or chemical resistance and use with special media (such as bio-degradable fluids, diesel oils, gasolines, etc.) as well as special sealing materials are available on request. Electrical Specifications ▪ Magnetic float activates switch when fluid level drops below contact level within 60 mm / 2.36 in of lower banjo bolt ▪ Available as a break contact...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Visual / electrical fluid level indication in hydraulic reservoirs with maximum tank pressures not exceeding 2 bar / 29 PSI; ideal for applications in which space is limited Nominal Sizes and Designs ▪ 5 nominal sizes from 127 mm / 5.00 in to 305 mm / 12.00 in ▪ Compact design allows space-saving installation: ▪ Always 40 mm / 1.57 in shorter than Level Gauges SNK of the comparable nominal size ▪ Display either undivided (SNKK 127 ... 176) or subdivided by strut(s) into 2 (SNKK 254) or 3 sections (SNKK 305) Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Materials ▪ Housing made of Aluminium, black powder coating ▪ Sight tube and plugs made of Polyamide (PA) ▪ Float made of Polyamide (PA) ▪ Sealings made of FPM (Viton®) Special sight tube materials for improved UV or chemical resistance and use with special media (such as bio-degradable fluids, diesel oils, gasolines, etc.) as well as special sealing materials are...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Visual fluid level indication in hydraulic reservoirs with maximum tank pressures not exceeding 2 bar / 29 PSI; ideal for custom applications in terms of reservoir capacities and dimensions Nominal Sizes ▪ Special sizes beyond the normal of 305 mm / 12 in up to a maximum nominal size of 950 mm / 37.4 in – even for small and medium quantities ▪ High-precision manufacturing within 1 mm tolerance to customer requirements Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Designs ▪ Robust design thanks to one or more struts that subdivide the display into 2 or more sections ▪ Positioning of the strut(s) based on engineering considerations and/or according to particular customer requirements ▪ Precise visual indication of the fluid level by use of scale plates (only available for nominal sizes smaller than 670 mm / 26.4 in) or by use of a coloured floating element (recommended option for nominal sizes larger than 670 mm /...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Test Couplings with ball check for normal hydraulic applications and hydraulic applications with high-viscosity fluids. Area of Application ▪ Monitoring and control of pressure ▪ Venting ▪ Sampling in high- and low-pressure systems Advantages ▪ Coupling at system pressure level ▪ Leakproof connection before ball check is open ▪ Simple connection to measuring, control and switching devices Media ▪ Suitable for hydraulic oils and other mineral oil based fluids (Check compatibility of sealing material) ▪ For use in conjunction with other liquid media please consult STAUFF Working Pressure ▪ Max. working pressure 400 bar / 5801 PSI For SMK style G and K the recommended working pressure of fitting manufacturer has to be applied. Materials Metal parts made of: ▪ Steel, zinc/nickel-plated = C6F (CrVI-free) Ball made of Stainless Steel Sealings made of: ▪ P = NBR (Buna-N®) Temperature range -20 °C ... +100 °C / -4 °F ... +212 °F ▪ V = FPM (Viton®) Temperature range -20 °C ... +200 °C...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF is completing its extensive range of Mobile Filtration Systems of the SMFS series with another type: The SMFS-U-DL-015-G is the first unit that has the filtration components including a high-quality motor/pump unit used along with a sturdy transport cart for 200l / 52 US GAL oil drums with a weight up to 250 kg / 551 lbs. Either compact and versatile on the one hand, but also made for high loading capacity on the other hand, this filtration system is an essential tool for the in-plant service and preventive maintenance, either when transferring fresh fluids or purifying hydraulic and lubrication oil systems. Replacement Filter Elements ▪ Filter Elements of the Spin-On series SFC-57/58 ▪ Micron rating available from 3 ... 125 μm ▪ Also available with a blank filter element (SFC-5700) for the reason of used oil to be removed from the hydraulic reservoir Clogging Indicator ▪ Visual Pressure Clogging Indicator Type SPG-040 Lance ▪ Length 300 mm / 11.82 in Hose ▪ Available...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Test Couplings with piston valve for: ▪ Hydraulic applications with low-viscosity fluids (e.g. water, cooling lubricants, etc.) ▪ For high, pulsating pressures ▪ For customer philosophy “Soft sealing / non metal to metal seal” ▪ Pneumatic applications ▪ Natural gas applications with DVGW requirement SKK-DVGW ▪ Other gas applications without DVGW requirements SKK-GAS ▪ Filling (flow in opposite direction) SKK-FÜLL Area of Application ▪ Monitoring and control of pressure ▪ Venting ▪ Sampling in high- and low-pressure systems ▪ Filling of accumulators (special filling-version) Advantages ▪ Coupling at system pressure level ▪ Leakproof connection before ball valve is open ▪ Simple connection to measuring, control and switching devices ▪ Self locking metal guard cap Media ▪ Suitable for hydraulic oils and other mineral oil based fluids (Please pay attention to the sealing materials used) ▪ For use in conjunction with other liquid or gaseous media please consult STAUFF ▪ In case of...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Test Couplings with ball check for normal hydraulic applications and hydraulic applications with high-viscosity fluids. Area of Application ▪ Monitoring and control of pressure ▪ Venting ▪ Sampling in high- and low-pressure systems Advantages ▪ Coupling at system pressure level ▪ Leakproof connection before ball check is open ▪ Simple connection to measuring, control and switching devices ▪ Self locking metal guard cap Media ▪ Suitable for hydraulic oils and other mineral oil based fluids (Check compatibility of seal material) ▪ For use in conjunction with other liquid media please consult STAUFF Working Pressure ▪ Max. working pressure 630 bar / 9137 PSI For SMK style G and K the recommended working pressure of fitting manufacturer has to be applied. ▪ Joining under pressure up to 630 bar / 9137 PSI max. Materials Metal parts made of: ▪ Steel, black zinc/nickel-plated = C6F* (CrVI-free) Optional: ▪ Stainless Steel V2A (1.4305 / AISI 303) on request ▪ Stainless Steel V4A...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Test Couplings with piston valve for: ▪ Hydraulic applications with low-viscosity fluids (e.g. water, cooling lubricants, etc.) ▪ For high, pulsating pressures ▪ For customer philosophy “Soft sealing / non metal to metal seal” ▪ Pneumatic applications ▪ Filling (flow in opposite direction) SKK-FÜLL Area of Application ▪ Monitoring and control of pressure ▪ Venting ▪ Sampling in high- and low-pressure systems ▪ Filling of accumulators (special filling-version) Advantages ▪ Coupling at system pressure level ▪ Leakproof connection before ball valve is open ▪ Simple connection to measuring, control and switching devices ▪ Self locking metal guard cap Media ▪ Suitable for hydraulic oils and other mineral oil based fluids (Please pay attention to the sealing materials used) ▪ For use in conjunction with other liquid or gaseous media please consult STAUFF ▪ In case of ultimate tightness requirements for gaseous media, a special Gas-type is available Working Pressure ▪ Max. working...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Test Couplings with ball check for normal hydraulic applications and hydraulic applications with high-viscosity fluids. Area of Application ▪ Monitoring and control of pressure ▪ Venting ▪ Sampling in high- and low-pressure systems Advantages ▪ Coupling at system pressure level ▪ Leakproof connection before ball valve is open ▪ Simple connection to measuring, control and switching devices ▪ Self locking metal guard cap Media ▪ Suitable for hydraulic oils and other mineral oil based fluids (Check compatibility of sealing material) ▪ For use in conjunction with other liquid or gaseous media please consult STAUFF ▪ In case of ultimate tightness requirements for gaseous media, a special Gas-type is available Working Pressure ▪ Max. working pressure 630 bar / 9137 PSI For SMK style G and K the recommended working pressure of fitting manufacturer has to be applied. ▪ Joining under pressure up to 400 bar / 5801 PSI max. Materials Metal parts made of: ▪ Steel, zinc/nickel-plated = C6F...

Request for a quoteResults for

Hydraulic fluids - Import exportNumber of results

36 ProductsCountries

Company type