- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hot water boiler

Results for

Hot water boiler - Import export

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

The UT-H is suitable for processes in high temperature and pressure ranges. The boiler can also convert to climate-neutral fuels which makes it a future-proof solution. — High-pressure hot water boiler from 820 to 18,300 kW with very high efficiency levels — Versatile operation for the manufacturing industry and district heating grids with temperature levels up to 225 °C — Customer-specific design and future-proof technology — User-specific control which offers integration of other control systems and remote monitoring — Custom designs for heat recovery boilers — Proven and reliable construction Made in Germany

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

Simple operation and fully automated operation of up to four hot water or heating boilers (master/slave). Compact "plug and play" control with innovative connectivity. — Modular complete solution with cost advantage, for all single-flame-tube hot water and heating boilers — Intelligent sequence control for up to four boilers — Intuitive operation via colour touch display and function keys for quick access — Pre-configured and completely wired for quick commissioning — Integrated power supply in the compact control cabinet, e.g. for burner and pumps — Compatible with all common automation system protocols — Optional remote access via MEC Remote for maximum availability

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

The various output sizes and temperature ranges up to 190 °C of the UT-M enable flexible operation for countless process heat and heating applications. — Efficient heat and process heat for low running costs and emissions — Compact design for easy positioning and quick heating — Flexible use for industrial, commercial and district heating applications with temperatures up to 190 °C — Project-specific control solutions and optional real-time monitoring — Complete system from a single source, low-emission or CO2-neutral customer-specific operation possible — Proven and maintenance-friendly construction for a long service life and reliability — Fuel: Oil, gas, multi-fuel firing, Biogas, bio-oil, hydrogen, special fuels

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

Two independent firing units and flue gas paths create a double control range for individual heat consumption. — Very high efficiency across all power ranges — Particularly suitable for highly fluctuating heat and process heat demand — Reliable solutions for heating plants and the manufacturing industry with temperature levels up to 225 °C — Heat supply for the future: Low-NOx or CO2-neutral operation possible — Complete system with intelligent control technology and protected remote connection — Proven and durable boiler technology Made in Germany

Request for a quote

KLÖPPER-THERM GMBH & CO. KG

Germany

The energy market called for technical solutions contributing to a mains stabilization and benefiting from the potential of favourable energy prices at the same time. The warm water boilers can be delivered in a power range from 35 kW up to 1.2 MW whereas the hot water boilers are available with a capacity of max. 10 MW. By means of parallel or series connection of several systems the power range can be extended optionally. The functional principle of warm and hot water boilers relies on the direct heating of flowing water via numerous resistance heating elements. For control purposes, they are summarized in groups which are either switched in steps or triggered infinitely variable via a thyristor power controller.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Project-specific control system for optimum control of steam or hot water boilers — Maximum supply and operating reliability thanks to integrated monitoring and protection functions — Condition monitoring for consistently high system efficiency and availability of steam, hot water and heating boiler systems — Intuitive operation with graphical symbols and state-of-the-art touchscreen displays — SUC start-up, standby and shutdown system allows fully automatic high pressure steam boiler operation — Easy connection to higher-level visualisation and control systems as well as remote access via MEC Remote

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

A flue gas heat exchanger is part of the standard equipment for energy-optimised and environmentally friendly boiler operation. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 15% when using condensing technology — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting

Request for a quote

SANHA GMBH & CO. KG

Germany

The stainless steel heating circuit distributors are complemented by an extensive accessory programme. Alongside cabinets for wall-mounted and concealed installtion, there are fittings and installation kits for the primary connection and bridging joints for the secondary side. Room thermostats and actuators alloe precise control of the room temperature. The unique pre-connected circuits, with an integrated pump, can be connected directly to the heating circuit. This makes it possible to integrate a low temperature circuit into an existing high temperature circuit. This eleminates the need for a separate hot water supply from the boiler and any works entailed. At the same time, the need for a separate hot water supply from the boiler and any works entailed are eliminated. A separate control circuit with extensive pipin g and troublesome interventions in the building structure is no longer necessary. regulating valve with internal sensor and integrated non-return valve

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

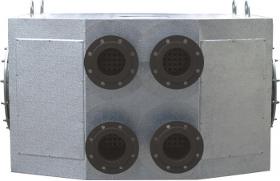

CHARACTERISTICS Decentralized application Optimal load-case design Optimized flow stream design Vibration-optimized design Leaflet: E-3015-Waterbath Heater / Type VH OPTIONS FOR HIGH PRESSURE TUBE BUNDLE Customer-specific design for various design codes (ASME, EN 13445, SVTI, AS1210, PD5500 etc.) Design according to TEMA Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Customer-specific nozzle arrangement Water jacket design as pressure vessel Water tank vessel for hot water> 100 ° C GENERAL Indirect water bath heaters type VH are heat exchangers (heat exchangers) which can heat the gas decentrally if no hot water treatment (for example a boiler system) is available. The heating of the gas is necessary in order to counteract the Joule-Thomson effect during pressure reduction or to provide a defined gas temperature for the following system components. The most common...

Request for a quoteResults for

Hot water boiler - Import exportNumber of results

10 ProductsCountries

Company type