- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high pressure dosing pump

Results for

High pressure dosing pump - Import export

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

High strength ePTFE-Graphite Characteristics Extrusion resistant even with large clearances Form stable, wear resistant, heat conductive and can be used as bull ring Shaft protecting (recommended surface hardness: HRC 25) In high pressure applications die formed rings are recommended Operating range Pressure [p max]: 30 bar, Velocity [v max]: 8 m/s Pressure [p max]: 800 bar, Velocity [v max]: 3 m/s Pressure [p max]: 500 bar Temperature: t = -200… +280 °C pH: 0 - 14 Density: 1.35 g/cm³ Main application High pressure plunger- and dosing pumps Bullrings for mixers, highpressure valves agitators, gate valves and valves Suitable for Chemical industry Petrochemical plants High pressure machine constructions Approvals BAM for liquid and gaseous oxygen 60 °C/15 bar, 40 °C/65 bar, 200 °C/50 bar Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special measurements. 03 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg...

Request for a quote

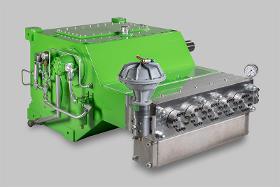

KAMAT GMBH & CO. KG

Germany

With a maximum drive power of 1000 kW, the K100000-5G high pressure pump is an extremely powerful pump. As a five-cylinder pump (quintuplex), it offers the possibility of pumping without inlet pressure in many applications. Its special five-cylinder design allows high flow rates without cavitation in the pump. Like its smaller counterpart, the K55000-5G, it is used for larger jetting or hydraulic applications. Special Features Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 10-100% depending on rod force dynamically balanced gear Gear unit with forced lubrication and oil cooling gear ratios i = 3.40 - 4.10 - 4.69 - 5.19 - 6.03 Also available to API 674, including vertical operation Filtration up to 350 µm Special media such as seawater, glycol, methanol, oils etc. on request

Request for a quote

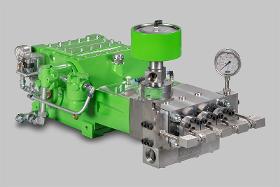

KAMAT GMBH & CO. KG

Germany

High-Pressure Cleaning, Load Change Systems and Pressure Test Systems If your application requires forced lubrication and an oil cooler may be required, the powerful K9000-3G three-plunger high-pressure pump is an alternative to the smaller K8000-3G three-plunger high-pressure pump. Like the compact K8000 model, this 90 kW high-pressure pump is suitable for smaller industrial applications such as industrial cleaning, jetting or process engineering. SPECIAL FEATURES - Capacities at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on fluid - Speed range 10-100% depending on rod force - Forced lubrication gearbox (> 75 kW with oil cooler) - Standard gear ratios i = 2.75 - 3.22 - 3.68 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request - Vertical operation possible

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for building up pressure in the polymer process. The series is the result of a complete revision of the core components used. The BOOSTER-AT is available with flange connections according to EN1092-1 and ANSI B16.5. Thanks to the new gear wheel geometries, differential pressures of up to 320 bar are possible with selected pump sizes. The new design is rounded off by the usual variety of different material combinations. Advantages: Higher efficiency, therefore Less temperature input into the polymer Wider viscosity range possible Larger volume flow range possible Increased safety against shaft breakage in case of overload due to new design

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The reliable booster pump for the polymer process. BOOSTER gear pumps from WITTE are used in the polymerisation process to increase the pressure of medium to high viscosity media. The hydraulically heated booster pump conveys very gently prepolymers and polymers, such as PET, PBT, PS, ABS and many others. Heating is by means of heat transfer oil or steam. The core components such as shafts and slide bearings come from the WITTE modular system. The booster pumps of the BOOSTER series are used wherever particularly high pressure is required for the process. High pressures are required for pelletising, fibre production or for spinning pumps, among others. The design of the BOOSTER booster pumps can be adapted to the needs of the plant and the customer's requirements.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

High pressure dosing pump - Import exportNumber of results

5 ProductsCountries

Company type

Category