- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heavy machines

Results for

Heavy machines - Import export

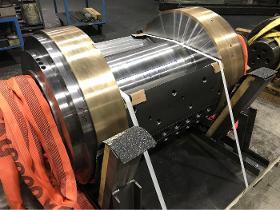

ING. KURT SCHADE GMBH & CO. KG

Germany

Our many years of experience in the fields of steel construction and CNC machining also make us a competent service provider in the field of repairs. Contact us – together we will find the optimal solution!

Request for a quote

ING. KURT SCHADE GMBH & CO. KG

Germany

With the complete assembly of assemblies, we offer you an all-round package: - We buy all the materials you need. - We straighten, staple and MIG MAG weld the individual steel construction components exactly according to your specifications and complete the components using high-precision CNC machining. - We assemble the finished, repeatedly tested components in our 2000 square meter assembly hall according to your construction plans into ready-to-install modules. - We check the final assembly down to the smallest detail. - We deliver the finished end product to you. Are you looking for a reliable service provider to implement your next project? We look forward to your inquiry.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

Rigid machine for heavy duty belt grinding. The machine can be adjusted for horizontal or vertical position. Various options include: Dust extraction, chamfering device, angle guide roller, longitudinal stop.

Request for a quote

ING. KURT SCHADE GMBH & CO. KG

Germany

With our modern CNC boring machines, CNC milling machines and CNC lathes we work on steel construction components and process forgings and castings into precision components for mechanical engineering. Our cutting machine operators work precise on parts that are up to 10 meter long and weigh 25 t - with an accuracy of 0.01 millimeters. This is how customized mechanical engineering elements are created, such as: - wind power components - press stand - gear housing for mining ... The machining technicians create the individual CNC programs together with our CAD specialists directly on the CNC machines. An integrated management system and the uniform control concept from Heidenhain guarantee a high degree of flexibility; all CNC machines for heavy-duty machining are networked and access a central data pool. This is how we guarantee you fast programming and set-up times, absolute repeatability and adherence to schedules.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With our clockwise/counterclockwise bending machines the most complex bends become reality with great accuracy. The Bending head of our fully electric CNC R/L series can be positioned horizontally and vertically, including 360° rotation axis for a change of bending direction (right- or left-hand). For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times. Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most complex geometries on tubes. Our robust machine construction means customers have come to expect decades of heavy use. This machine is supplied with an easy-to-use Siemens CNC control system, which utilizes an intuitive program in a Windows based operating system set up for networking.

Request for a quote

ELKON GMBH

Germany

With more than 44 years of experience, technological production and innovative approach in concrete machinery, ELKON has designed premium block making machine aiming at sustainable high quality and optimum performance in block production. ELKOBLOCK-36M which is specially designed by experts in their field to produce different types of blocks such as interlocks, curb stones, solid blocks, etc. has the capacity to produce concrete paving stone over 1.000 square meters in an 8 hours shift. Heavy duty design, robust machine structure and certified high grade steels used in production ensures highest durability and longest life time. Four columns system with chrome-plated guides for tamper head improves stability of machine and guarantees parallel movement of tamper head.

Request for a quote

TROTEC GMBH

Germany

With 400 watts of power, the submerged pump TWP 4006 E moves the masses. Being a flexible helper in the home, garden and business, the universally applicable submerged clear water pump with its high flow rate is suitable for recirculating and pumping only slightly contaminated clear water (with dirt particles sized up to 5 mm) out of swimming pools, wells, rain barrels, cisterns or rainwater tanks. Similarly, the submerged pressure pump TWP 4006 E with near-ground suction can be used to dry out basements and washrooms that have been flooded due to heavy rainfall, washing machine leaks or the ingress of groundwater, leaving "wipe-dry" results and a low residual water level of only 5 mm. When used as a drainage pump in a drainage shaft, the robust pump, which is protected against the ingress of water by IPX8 type of protection, ensures that the accumulated rainwater is pumped out in a controlled manner.

Request for a quote

TROTEC GMBH

Germany

With the powerful 750 W submerged pump TWP 7506 E, even large quantities of water can be transported in a very short time. The powerful high-performance pump with near-ground suction is recommended for universal use in the house, garden and business to pump out or recirculate slightly contaminated clear water (dirt particles sized max. 5 mm) in indoor and outdoor pools, whirlpools, garden wells, rain barrels, cisterns and rainwater retention basins. Moreover, the submerged clear water pressure pump can be used to dry out basements and living spaces flooded by washing machine leaks, heavy rainfall or the ingress of groundwater, leaving "wipe-dry" results and a low residual water level of 5 mm. When used in waterproofing of buildings, the TWP 7506 E pump, which is protected against the ingress of water by IPX8 type of protection, impresses as a low-maintenance and durable drainage pump for pumping accumulated rainwater or groundwater out of the drainage shaft in a controlled way.

Request for a quote

SPIROL

Germany

Some of SPIROL's standard Pin Installation Models can be equipped with a pusher punch (in place of a pin insertion quill) to press Threaded Inserts into plastic assemblies. The most appropriate Installation Machine depends on the actual insertion force required to press the Insert into the plastic hole and the desired productivity. Generally speaking, the Model PMH Heavy Duty Installation Machine is typically used for low to medium volume installation, and for medium to high volume installation, SPIROL's Model PH/PHX Platen-Style Installation Machines can be used for simultaneous installation of several Press-In Inserts at the same or different elevations. Due to the length to diameter ratio of Press -In Inserts, it is not possible to cost-effectively tube feed this type of Threaded Insert with SPIROL's automatic feeding and Installation machines.

Request for a quote

SPIROL

Germany

SPIROL's Model DP self-contained vertical drilling and pinning machine is ideally suited for moderate to high production applications that require accurate drilling and pinning of assemblies. The concept of drilling and pinning with one system eliminates tight tolerance and precision drilling of individual components to ensure proper alignment of holes for assembly. The Model DP Drilling and Pinning Machine consists of an automatic high-precision drilling unit, a SPIROL Model CR Heavy Duty Pin Insertion Machine and a precision air-powered linear slide unit to move the assembly between the drill unit and installation station. The Model DP Drilling and Pinning Machine can drill holes ranging in diameter from 0.8mm-6mm (.031”-.250”) and is capable of insertion forces up to 8 kN (1,800 lbs).

Request for a quote

FORMHAND AUTOMATION GMBH

Germany

The ability to gently grip components of different dimensions, geometries and surface structures opens up completely new possibilities. Benefit from ✅ Increased efficiency of your processes ✅ Higher availability of your personnel ✅ Increased production speed ✅ Simple plug & play commissioning thanks to decentralized blower technology ✅ Modular design to increase performance Minimize ❌ Set-up times ❌ Maintenance costs ❌ Employment of personnel ❌ Process complexity Possible applications of the FH-E3020 ✅ Industrial robot applications for components up to 25 kg ✅ Loading and unloading of machines (e.g. press shop and body shop) ✅ Transporting parts (e.g. large, flat sheet metal parts such as fenders or hoods) ✅ Transportation of fragile parts ✅ Use in systems with high component variability ✅ Tube lifter applications

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

STRONG. SOLID. LONG-TERM ACCURACY - Travelling column machining centers with modular equipment variants and particularly high performance. STABILITY, YOU CAN FEEL! - Combination of extremely rigid & stable machine - High stability during machining - Extremely high rigidity sets new standards for moving column machining centers LONG-TERM ACCURACY - Long-term machining with consistent product quality - High precision even after years of use CUSTOMIZED MACHINE SOLUTIONS - Joint development of your milling strategy - from development to commissioning - Expertise from individual to series production, also automated 24/7 - Possibility of integrated automation FLEXIBILITY THAT INSPIRES! - Wide range of options | rotary table, magnetic table, swivel table, additional magazine, partition wall, etc. - From heavy-duty machining to high-precision finishing of a wide range of materials

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK

Germany

Our workshop is equipped with CNC boring mills SCHMIDT Zerspanungstechnik's modern machinery offers a variety of options when it comes to the contract manufacturing and machining of work pieces and large machine parts. As a reliable machinist of large parts, SCHMIDT Zerspanungstechnik relies on state-of-the-art CNC boring mills whose complex movements are controlled by computer and which can be programmed. The employees working in our machine shop have modern 5-axis boring mills with axis travels of 3,500 x 2,000 x 1,500 mm at their disposal. They allow us to perform heavy-duty machining jobs as well as all other typical milling work. Our complete mastery of this flexible manufacturing process guarantees high-quality results are achieved in the most efficient way.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK GMBH

Germany

Our workshop is equipped with CNC boring mills SCHMIDT Zerspanungstechnik's modern machinery offers a variety of options when it comes to the contract manufacturing and machining of work pieces and large machine parts. As a reliable machinist of large parts, SCHMIDT Zerspanungstechnik relies on state-of-the-art CNC boring mills whose complex movements are controlled by computer and which can be programmed. The employees working in our machine shop have modern 5-axis boring mills with axis travels of 3,500 x 2,000 x 1,500 mm at their disposal. They allow us to perform heavy-duty machining jobs as well as all other typical milling work. Our complete mastery of this flexible manufacturing process guarantees high-quality results are achieved in the most efficient way.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOLZ PROCESS TECHNOLOGY GMBH

Germany

COMBER Termomix® Series TM 1000 - TM 40000 The Termomix vacuum paddle dryer/reactor is intended for monoproduction applications or bulk production facilities as mixer, reactor, precipitator and dryer. Special properties for the customer’s benefit: Economic, robust multipurpose machine for heavy industrial applications The agitator is supported on both ends providing excellent mixing characteristics, with externally interchangeable stuffing boxes or mechanical seals Large heating area resulting in an outstanding heat transfer rate by heating the vessel walls, the vessel ends as well as the agitator shaft and arms

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

This encoder can be integrated inside the "Pin Joint" of heavy machinery equipment. The mounting is straightforward. This encoder is completely integrated in the joint and avoids external parts.

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability -Particularly suitable for single-piece production if you wish to make your vice rotatable -Can be removed at any time -Swivel base supporting edge larger than the vice‘s maximum clamping range -Swivels 360° without indexing -Alignment on the machine with T-keys in slots in the swivel base -Clamping slots arranged in the form of a ring for machines with different slot spacings

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Suitable for heavy machining work, single pieces and small batches -Designed particularly for use on conventional milling machines Product features: -Clamping force preselection, 2 to 4 increments, allows accurate repetition (type 100 – 2 increments; types 125, 160 – 4 increments) -Our tried and tested HD vice enables problem-free working with high clamping force and long-term reliability -Particularly suitable for single-piece production if you wish to make your vice rotatable -Can be removed at any time -Swivel base supporting edge larger than the vice‘s maximum clamping range -Swivels 360° without indexing -Alignment on the machine with T-keys in slots in the swivel base -Clamping slots arranged in the form of a ring for machines with different slot spacings

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The millGrind series is specially developed for the requirements of machining in the turbine industry as multiple technology solution in one set-up. The modular machine system in travelling table design allows an individual configuration of the machine according to the customers' needs. Automatic tool and diamond roll changing allows the machining to machine with — Al-oxide, CBN and diamond grinding wheels — Drills — Milling cutter — Laser cladding — Measuring of the unfinished workpiece — Measuring of the machine workpiece including rework in one set-up. This guarantees that all machined surfaces run to each other and errors are avoided by repeated re-chucking. In addition to the machining of new blades and vanes for rework a laser cladding device can be added. This allows the measuring, cladding and grinding or milling of the worn areas.

Request for a quote

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

The powerLine technology machines are specifically geared towards creep-feed grinding applications. Their mono-base design allows grinding widths (Z-axis) of up to 700 mm with a maximum spindle power of 105 kW. The compact, steel base designed powerLine model is equipped with linear guides in all three axes. All three axes (X, Y, Z) are driven by servo motors via ball screws (KGT). The standard version of the multiLine comes with high-precision linear scales for positioning of the vertical axis. The direct drive of the grinding spindle from 48 kW guarantees optimal torque transfer. Different measuring devices and CD (continuous dressing) units are examples of a wide variety of available options making it easy to customize the powerLine to your individual requirements.

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

Floor type milling machines stand for flexibility, productivity, and maximum precision. All machines are hallmarked by optimum rigidity and dynamics and offer maximum productivity. The machine design guarantees optimum interaction between operator and machine. Areas of application include mechanical engineering, tool and mold making and contract manufacturing for machining large parts with heavy unit weights. - Machining of large parts in pendulum mode - Machine for large workpieces with precision Longitudinal (X): 3,000 mm – unlimited Vertical (Y): 1,800 – 8,000 mm Cross (Z): 1,300 – 1,900 mm Quill (W): 700 – 1,000 mm

Request for a quote

F. ZIMMERMANN GMBH

Germany

Extremely high structural rigidity together with very fast-acting drives. Reinforced portal, cast side stands, high structural stability. Top surface quality and excellent dynamic response. Ideal for machining steel, cast iron and heavy materials like titanium. Spindle-change concept for economical complete machining. Advantages: - top surface quality - better dynamic performance - high efficiency

Request for a quote

UNIVERSAL ROBOTS (GERMANY) GMBH

Germany

The Universal Robots UR16e delivers an impressive 16kg (35.3 lbs.) of payload within a small footprint, and is ideal for use in heavy machine tending, material handling, packaging, and screw and nut driving applications. This powerhouse robot allows for heavier end of arm tooling and multi-part handling, and is especially useful for achieving shorter cycle times. The UR16e collaborative industrial robot is easy to program, offers fast set-up, is collaborative and safe, and like our other collaborative robots, offers one of the fastest payback times in the industry.

Request for a quoteResults for

Heavy machines - Import exportNumber of results

33 ProductsCountries

- Germany (33)

- Bonn, Düsseldorf and North Rhine and Westphalia (8)

- Frankfurt am Main and Hesse (1)

- Hannover and Lower Saxony (4)

- Kiel and Schleswig-Holstein (2)

- Mainz and Rheinland-Pfalz (1)

- Munich, Nuremberg and Bavaria (8)

- Saarbrücken and Saarland (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (7)

- Weimar and Thuringia (1)

Company type

Category

- Machine tools - metal machining (6)

- Bending machine tools (4)

- Mechanical engineering - custom work (3)

- Adjustment - machine tools (2)

- Screw cutting - steels and metals (2)

- Submersible pumps (2)

- Concrete mixers (1)

- Automation - systems and equipment (1)

- Finishing of surfaces - machinery (1)

- Hand tools, non-power (1)

- Machine tools, metal machining - parts and accessories (1)

- Mechanical transmission - components (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Milling - machine tools (1)

- Milling - steels and metals (1)

- Potentiometers (1)

- Robotics (1)

- Sawmills - machinery and equipment (1)

- Steels and metals - machining (1)